Ultrasonic flow meter

A flow measuring device and component technology, which is applied in measuring devices, measuring flow/mass flow, liquid/fluid solid measurement, etc., can solve problems such as unsuitable flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

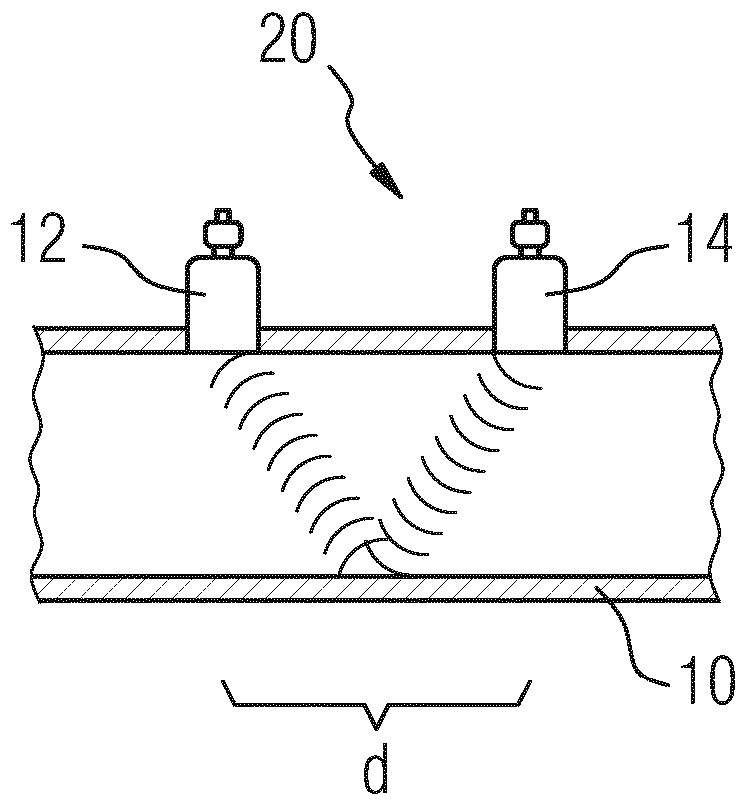

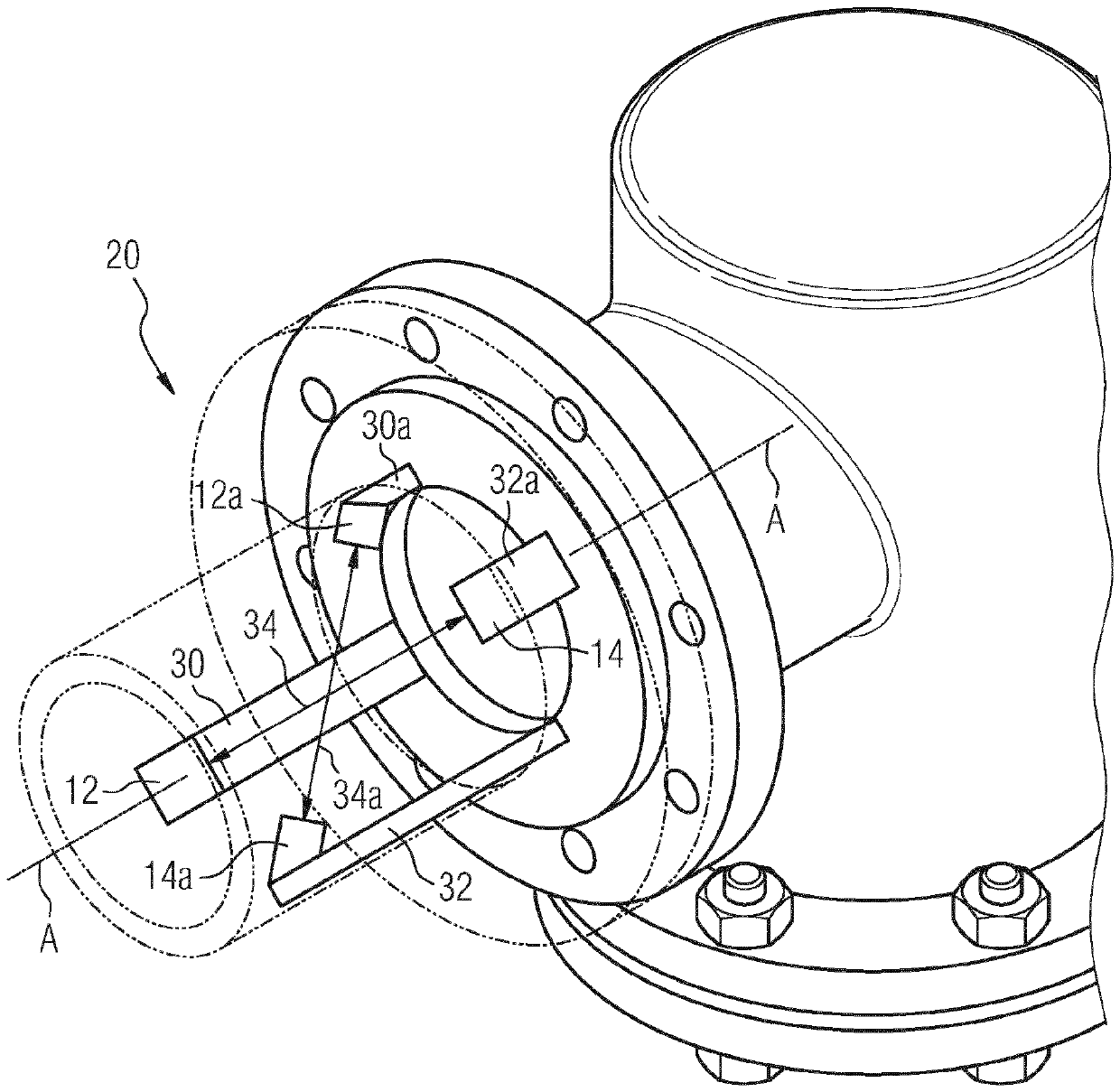

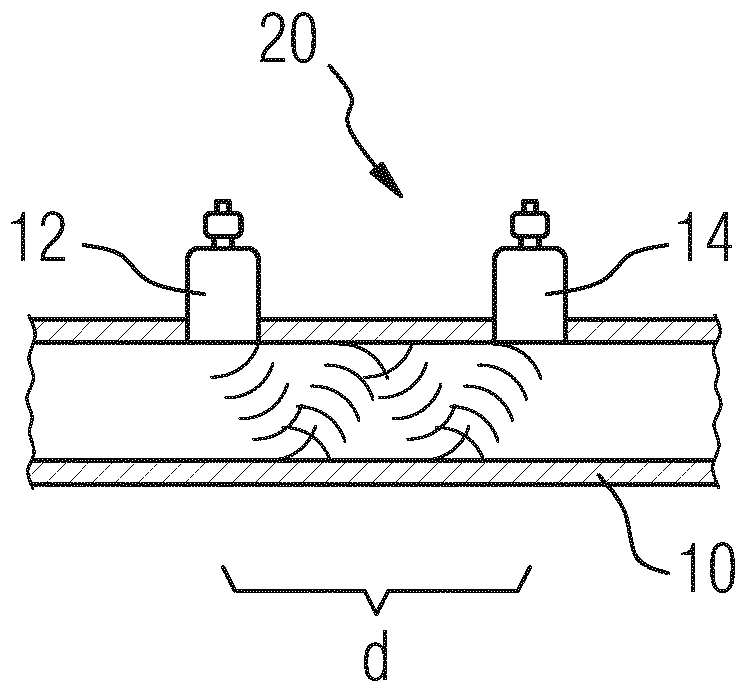

[0023] The measurement of the flow velocity of the medium in line 10 by means of ultrasound is known per se. The diagrammatic simplifications of FIGS. 1 , 2 and 3 show different configurations. A sensor pair is then assigned to the line 10 through which the medium flows, the flow velocity of which is to be ascertained. The sensor pair comprises a first ultrasonic sensor 12 and a second ultrasonic sensor 14 . The two ultrasonic sensors 12 , 14 , sometimes referred to below as sensors 12 , 14 for short and collectively as sensors 12 , 14 , operate as ultrasonic transmitters and ultrasonic receivers. The sensors 12 , 14 are arranged at a distance from one another in the flow direction of the medium flowing through the line 10 , ie in the axial direction of the line 10 .

[0024] Both sensors 12 , 14 function together as a flow measuring device 20 . The sensor signals of the sensors 12, 14 are evaluated by means of an evaluation device 22 belonging to the flow measuring device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com