Steel ball size automatic sorting device

An automatic sorting and steel ball technology, applied in classification, solid separation, filtering and screening, etc., can solve the problems of monotonous work, complex structure, and low efficiency of sorting steel balls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

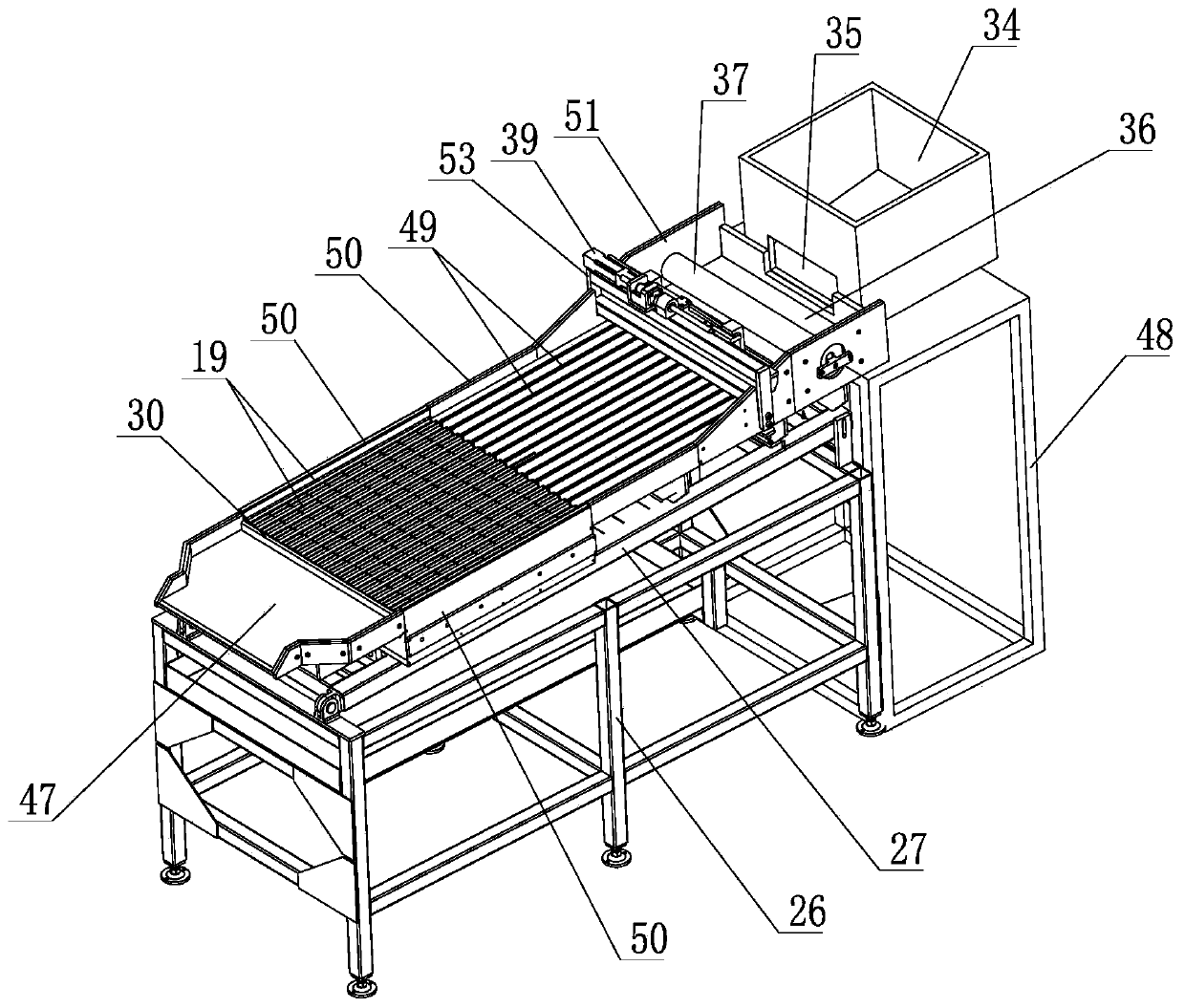

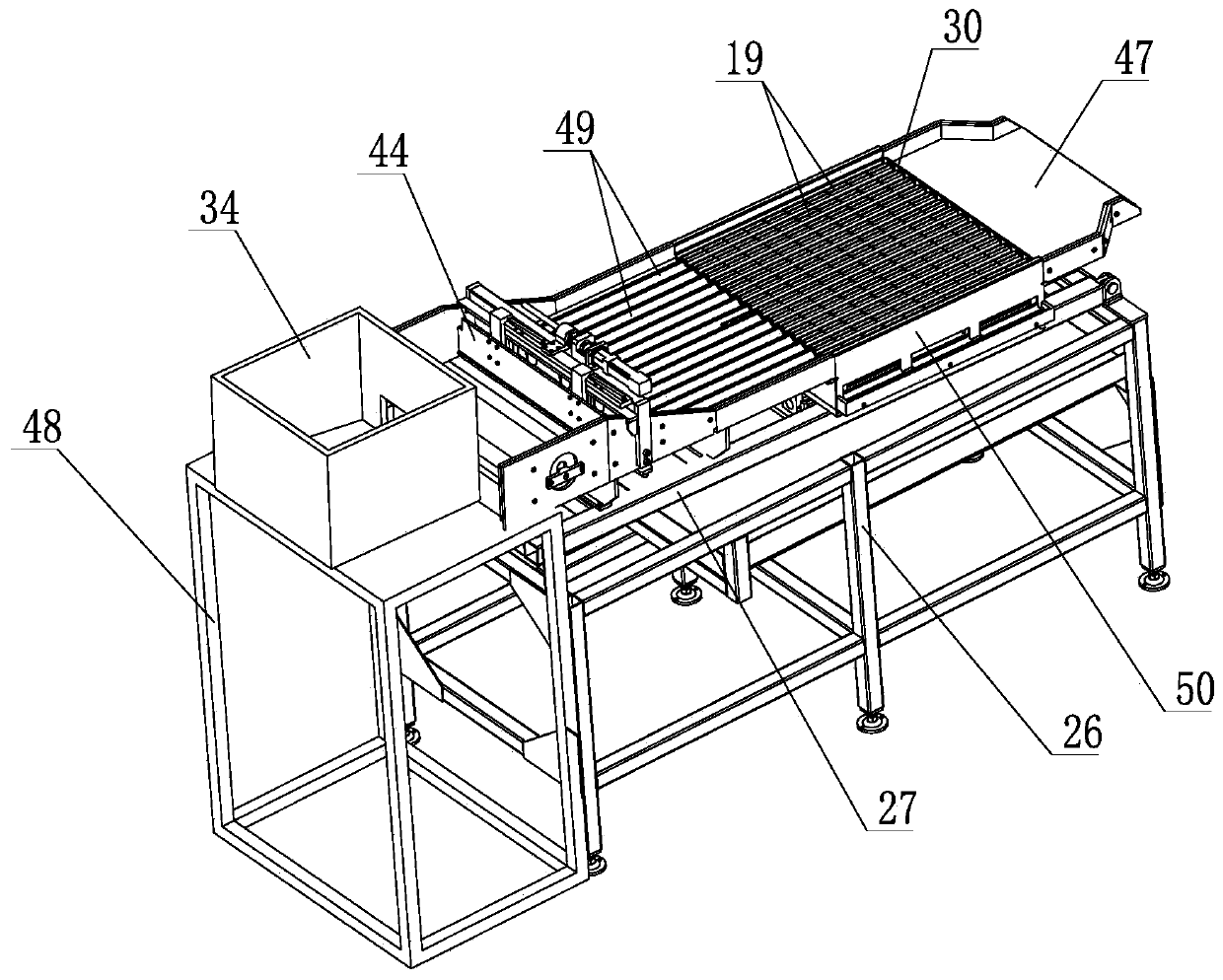

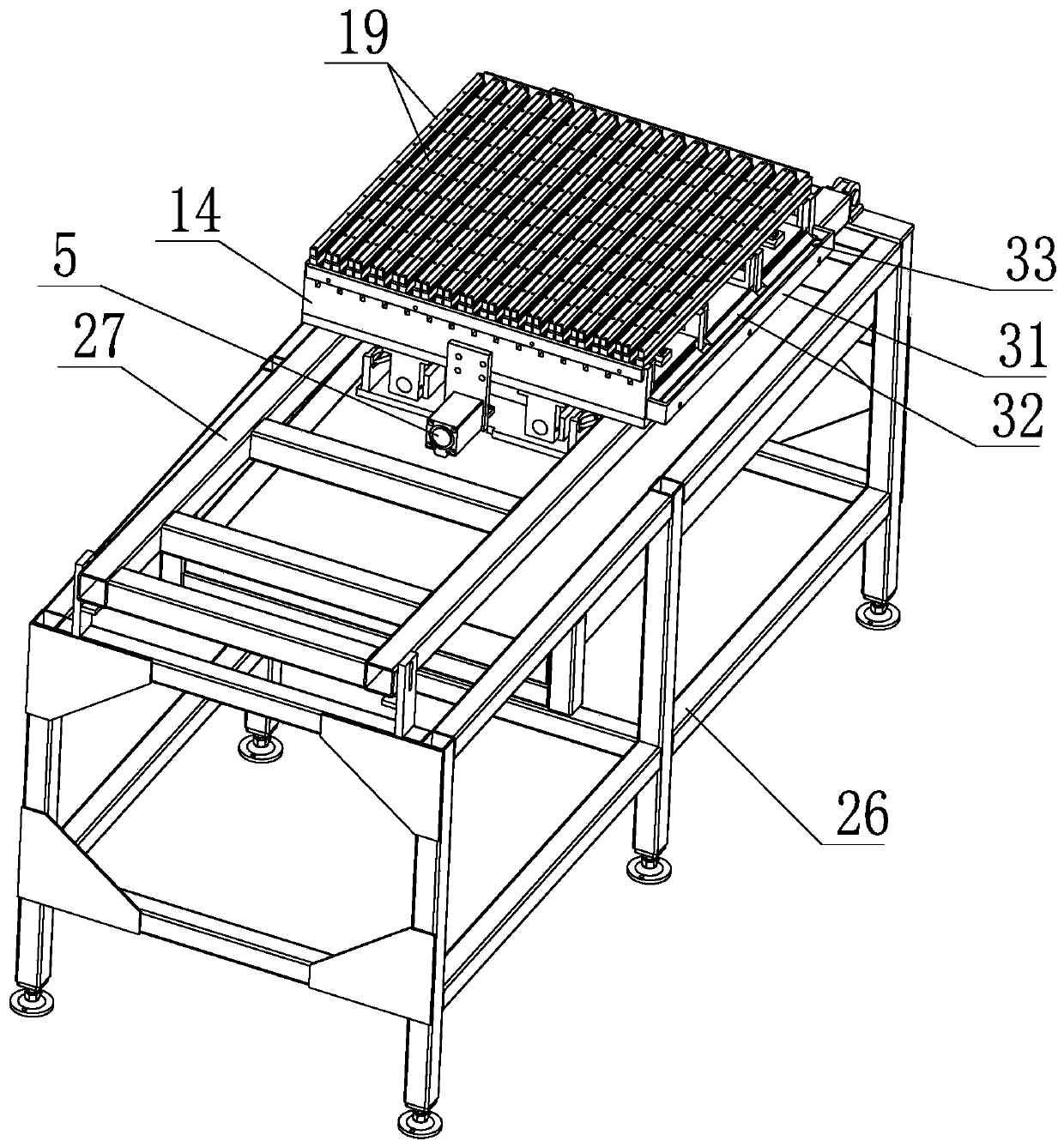

[0024] Specific embodiment one, please refer to Figure 1-3, a steel ball size automatic sorting device, comprising a guide rod 7, a bottom frame 26, an inclined frame 27, a feeding bracket 48 and a flat material box 36, the bottom frame 26 is provided with an inclined frame 27, and the inclined frame The front end level of 27 is higher than the level of the rear end, and the tilting frame 27 is fixed with tiling material box 36, steel ball arrangement channel 49, fixed guide rail mounting plate 16 and discharge port 47 successively from the front end to the rear end. The above-mentioned feeding bracket 48 is arranged on the front ends of the bottom frame 26 and the inclined frame 27, and the feeding bin 34 is fixed on the described feeding bracket 48, and the flat-laying material box 36 is close to the upper feeding bin 34, and the flat-laying material box 36 is close to the upper feeding bin 34. The both sides of material box 36 are provided with tiling material box side pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com