Automatic warehouse

A material warehouse, material feeding and discharging technology, applied in the field of automatic material warehouse, can solve the problems of single function, simple material warehouse structure, unable to meet the requirements of functionalization, intelligence, automation and flexibility, and achieve flexible use and high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

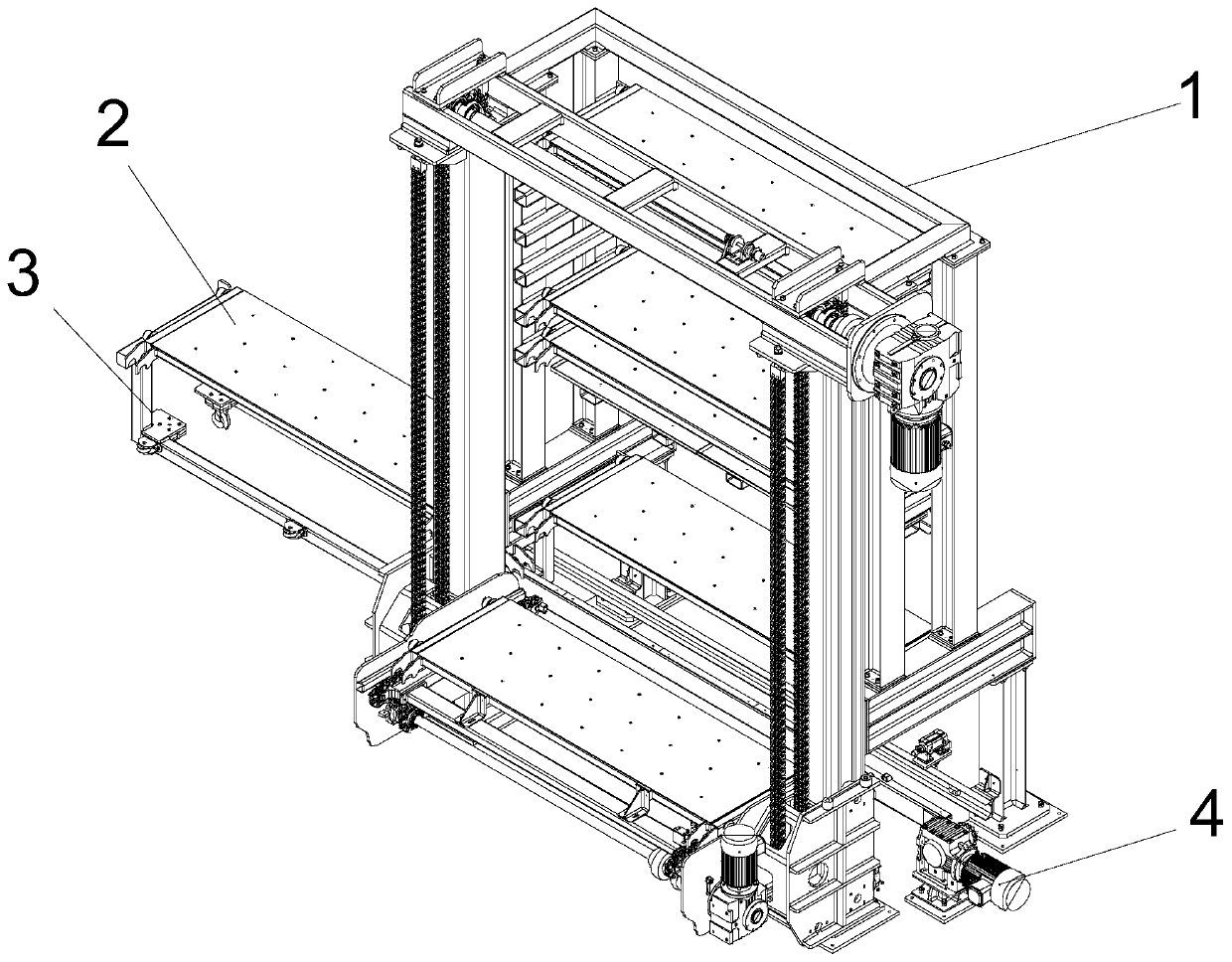

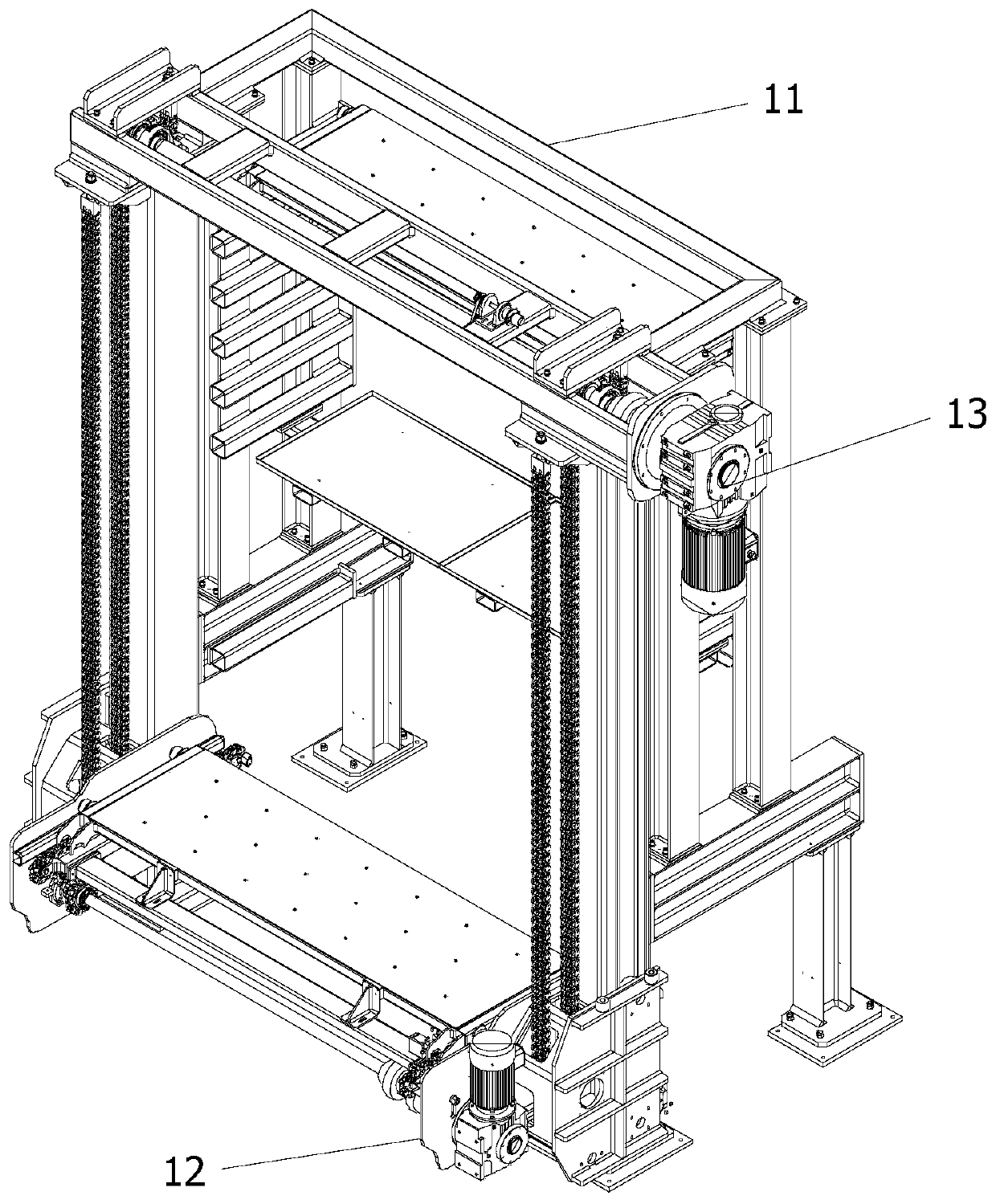

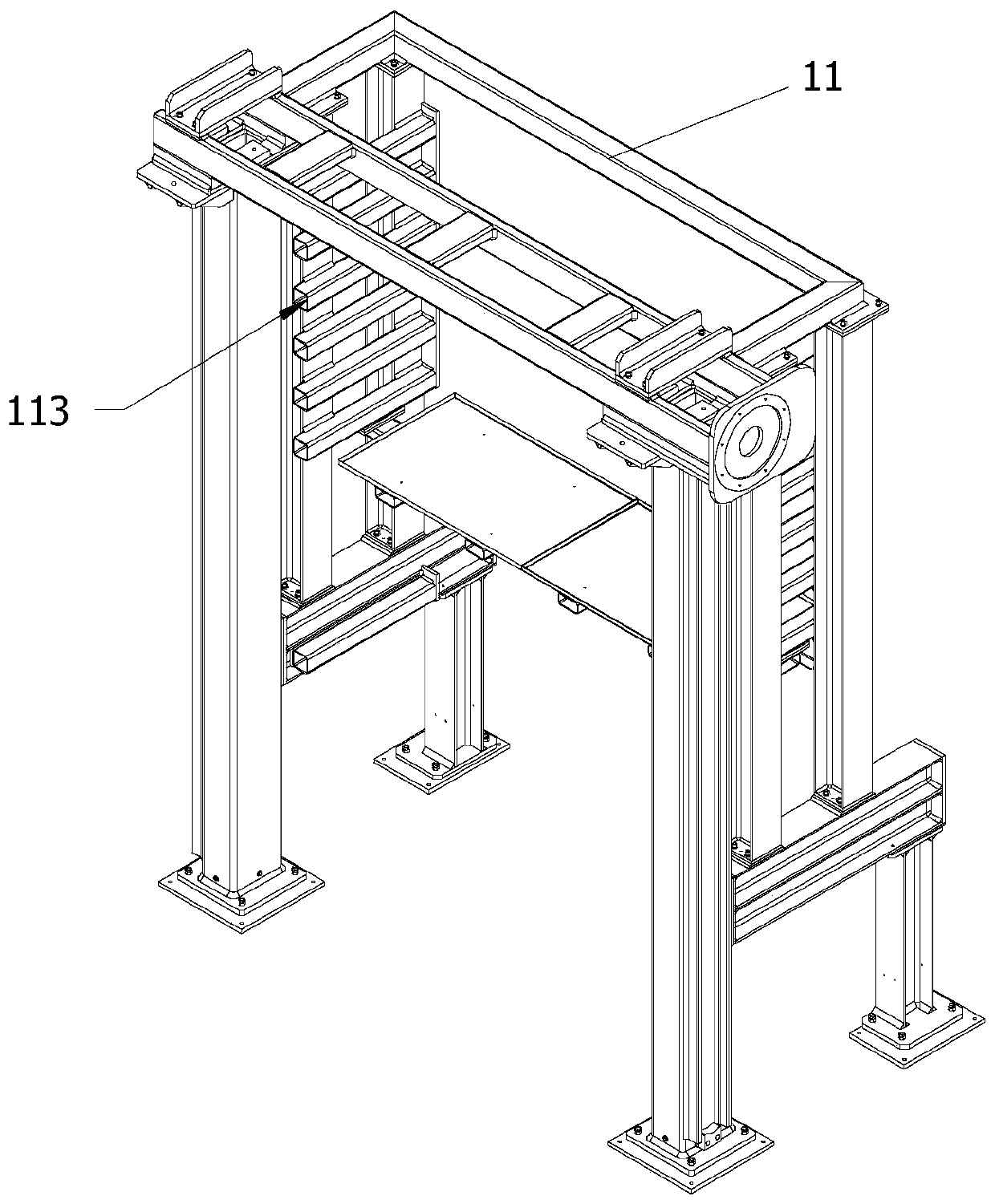

[0030] Please see attached figure 1 , an automated material warehouse, including a main body 1 of the material warehouse, a pallet 2, a feeding and discharging trolley 3 and a trolley walking system 4; please refer to the attached figure 2 , the main body 1 of the warehouse includes the main frame of the warehouse 11, the support for moving up and down the warehouse 12 and the system for moving up and down the warehouse 13, please refer to the attached Figure 4 , a pair of vertical door frame channel steel 112 is arranged symmetrically on both sides of the warehouse main frame 11, please refer to the attached Figure 6 A number of gantry channel steel bearings 1221 are symmetrically arranged on the up and down moving bracket 12 of the material warehouse. The steel 112 moves up and down. Preferably, there are four door frame channel steel be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com