Hoisting method for deck piping system unit module

A technology of unit modules and hoisting methods, which is applied in the direction of transportation and packaging, load hanging components, ship parts, etc., can solve the problems of easy deformation, large size and weight of large deck piping unit modules, and achieve the goal of preventing damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific embodiment:

[0020] One embodiment, a method for hoisting a deck piping unit module, the method includes the following steps:

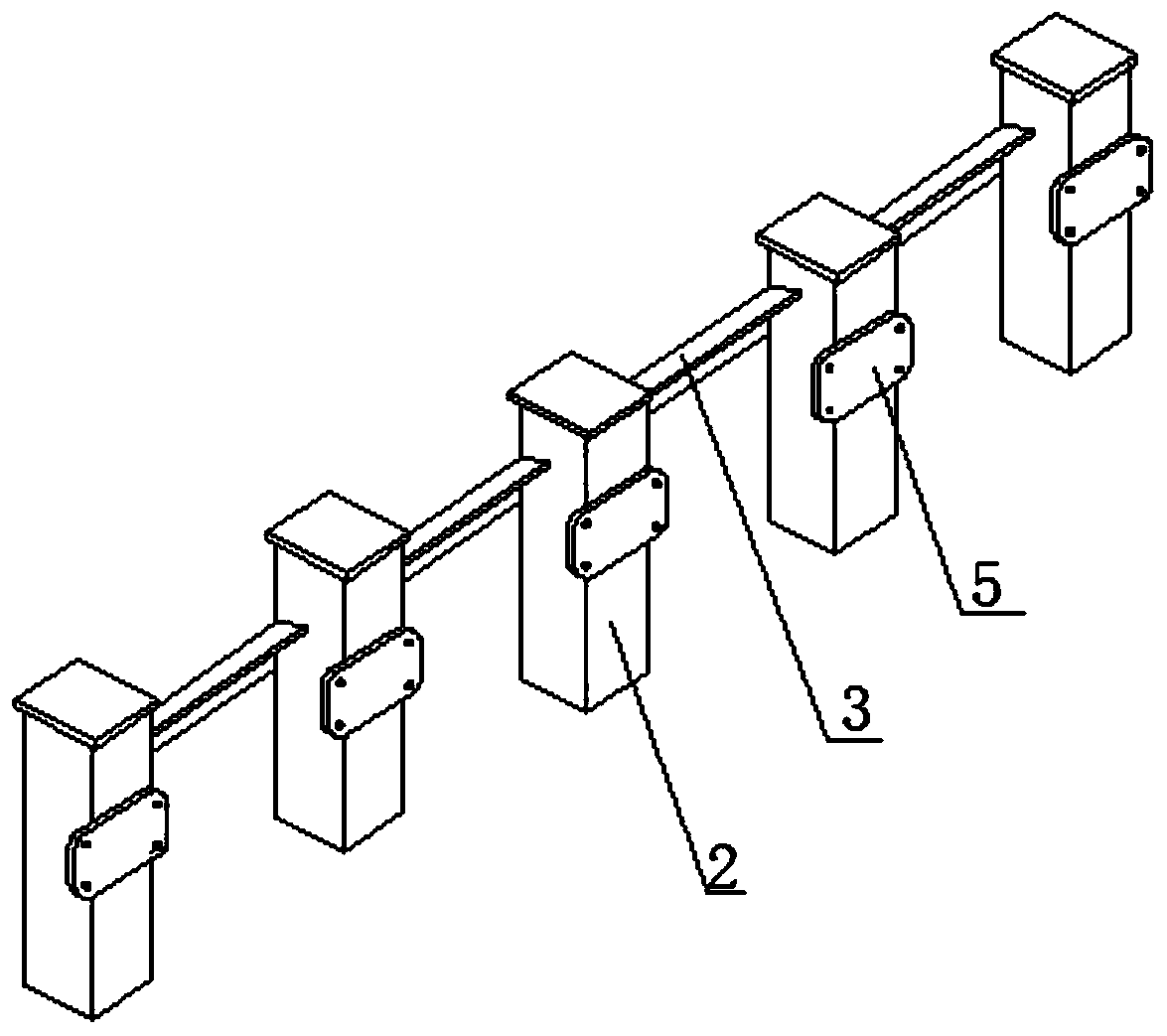

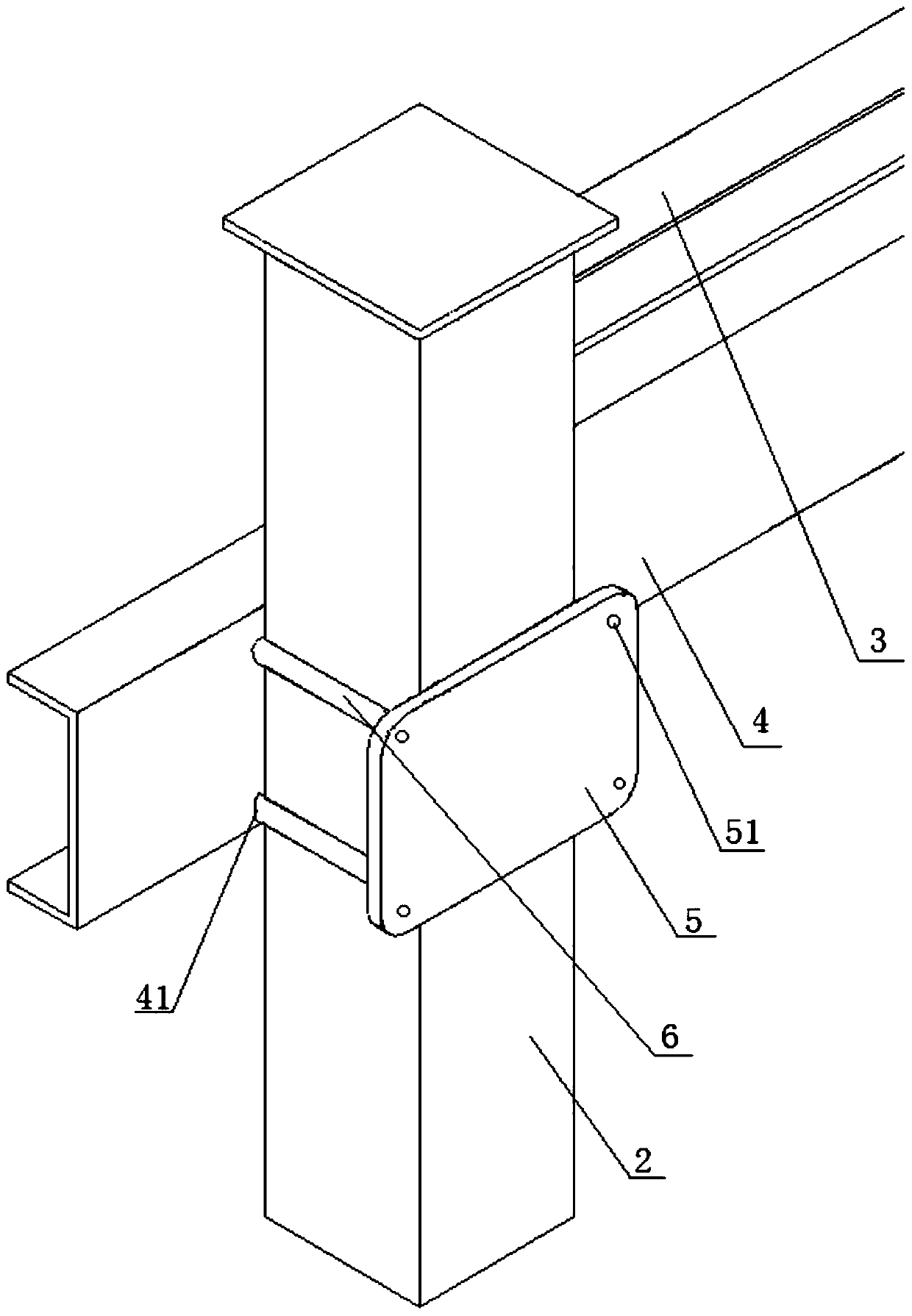

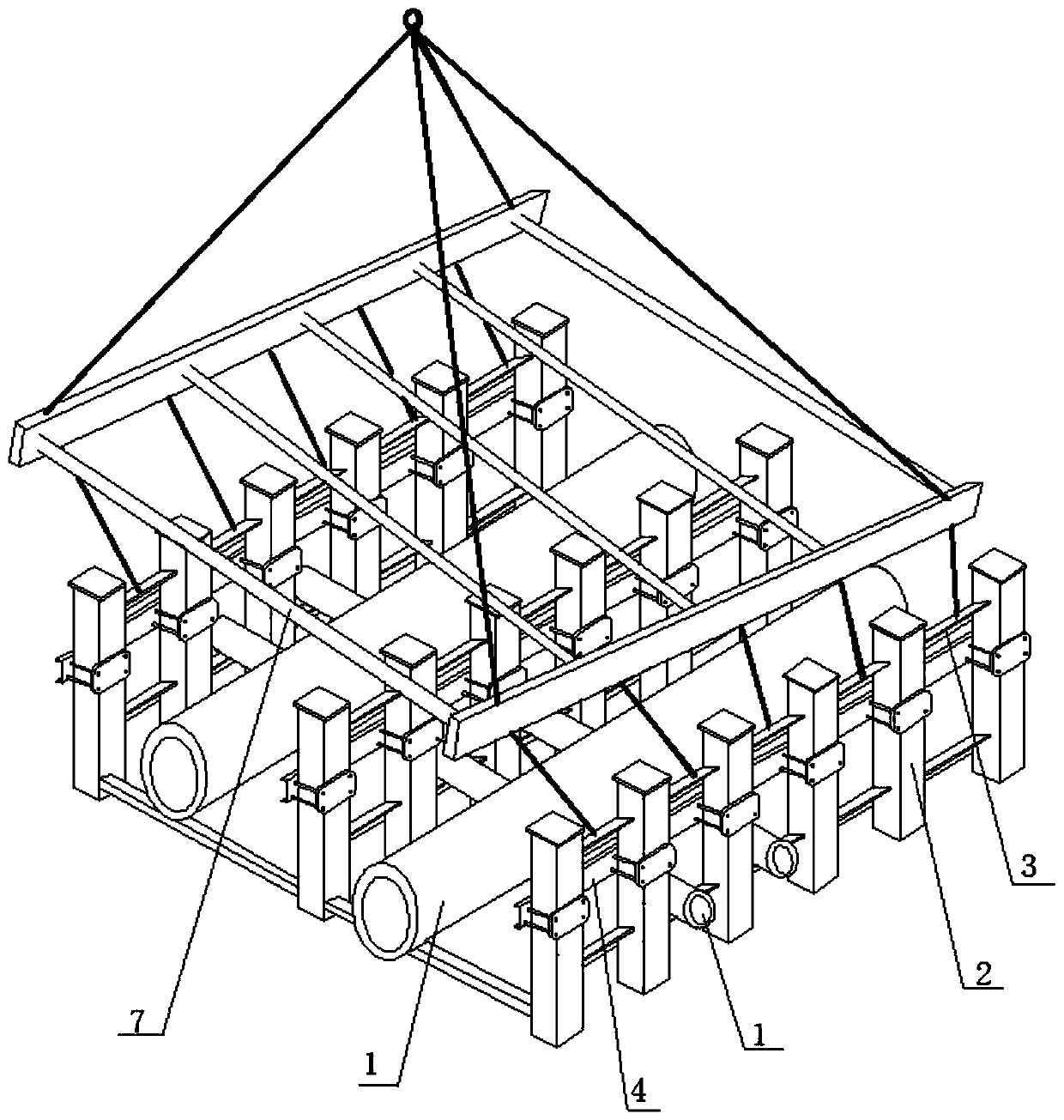

[0021] Step 1. Since the work of a large number of piping system and outfitting parts is moved forward, in the stage of unit module production design, the integrity design of the unit module needs to be carried out in advance, and the piping system 1, brackets, outfitting parts and reinforced connecting plates 5 are assembled into one body, as shown in image 3 As shown, the piping system 1 is fixed on the bracket. The bracket is composed of bracket square steel 2 and unit module large bracket 3. The unit module large bracket 3 crosses and perpendicular to the bracket square steel 2. The piping system 1 is mounted and fixed on the unit module large bracket 3. On the top, the large bracket 3 of the unit module is an angle iron of 180*180mm; the bracket square ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com