High-performance autoclaved aerated concrete integrated board external wall structure for fabricated buildings

An autoclaved gas filling and assembled technology, which is applied in the direction of building structure, building components, buildings, etc., can solve the problems of poor structural rigidity at the joints, and achieve the guarantee of thermal insulation and fireproof performance, excellent thermal insulation and fireproof performance, and good thermal insulation and fireproof performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

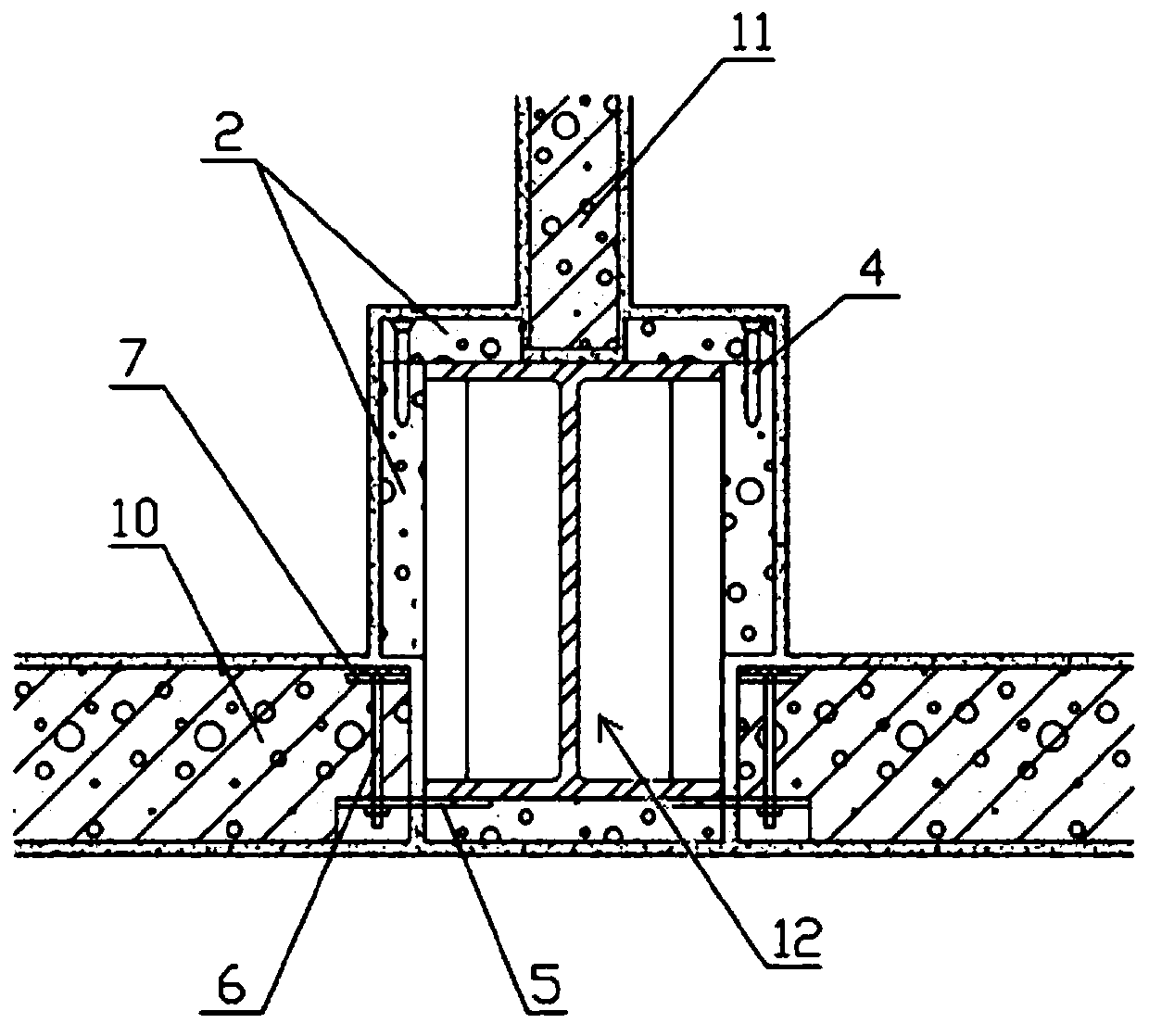

[0027] An embodiment of the present invention provides a high-performance autoclaved aerated concrete integrated panel exterior wall structure for a prefabricated building, including two sections of assembled exterior wall panels 10 and second connectors 12, wherein the two sections of assembled exterior wall panels 10 The adjacent ends are all provided with a first connecting piece, the first connecting piece specifically includes an embedded section, a connecting section and a steel connecting piece 5, the embedded section is embedded in the end of the prefabricated exterior wall panel 10, and one end of the connecting section It is connected to one end of the embedded section, and the other end protrudes from the fabricated exterior wall panel 10. The part of the steel connector 5 is attached to the fabricated exterior wall panel 10 and fixed to the connecting section protruding from the fabricated exterior wall panel 10. The remaining part protrudes from the end of the pref...

Embodiment 2

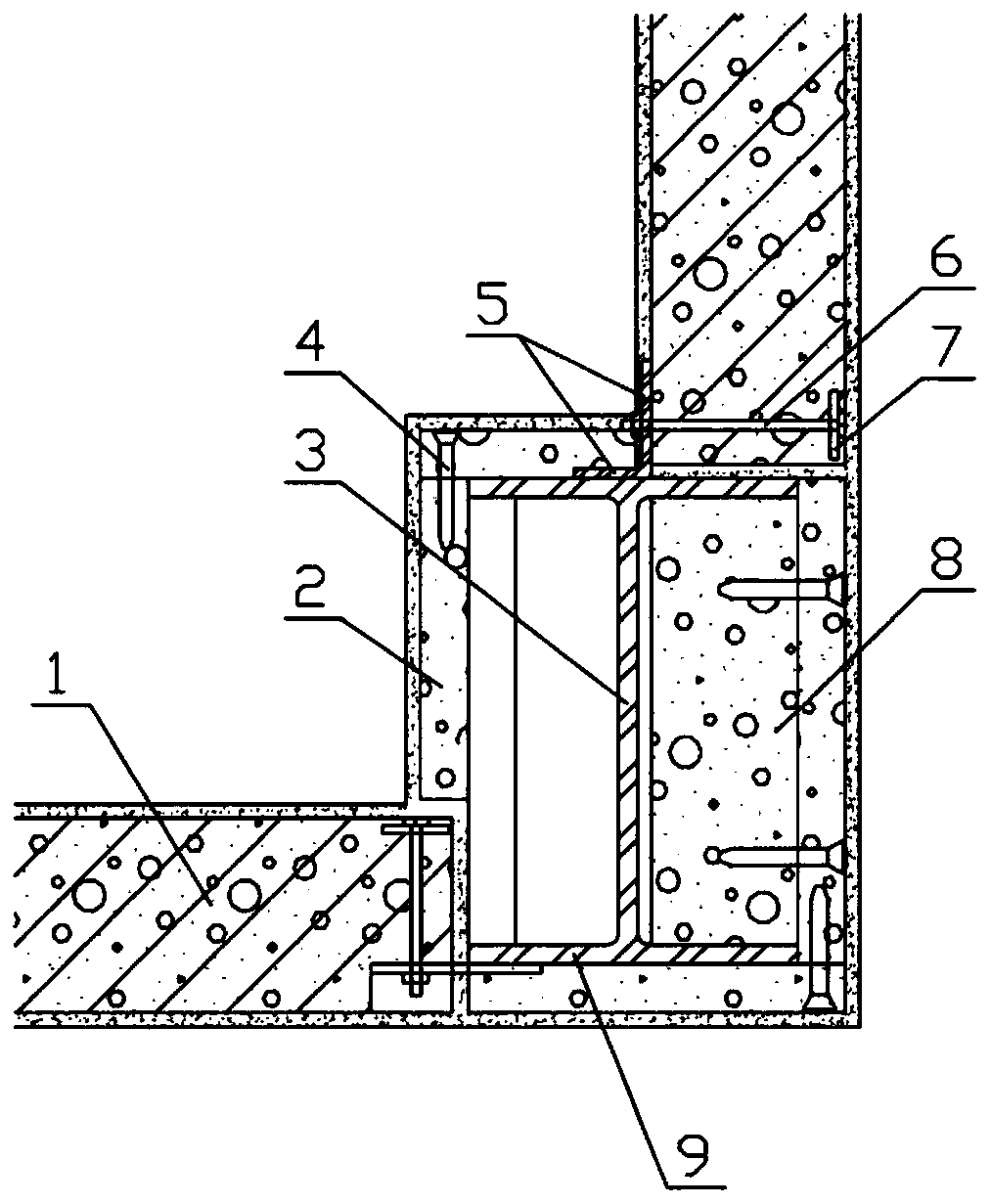

[0034] The present invention also provides a high-performance autoclaved aerated concrete integrated panel exterior wall structure for a prefabricated building, which includes a prefabricated exterior wall panel 10 arranged in the same plane and a prefabricated interior wall panel 11 arranged perpendicular to it and The I-shaped structural steel column, the fabricated exterior wall panel 10 and the fabricated interior wall panel 11 are all made of high-performance autoclaved aerated concrete integrated panels, and the fabricated exterior wall panel 10 is installed with steel connectors 5 and bolts 6 to work together. The outer wall structure of the prefabricated building in which the wing plates 9 in the I-shaped structural steel columns are welded together; the exposed parts of the I-shaped structural steel columns are covered with high-performance insulation boards 2 or high-performance blocks 8, and the adjacent The performance insulation boards 2 are connected by adhesive b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com