Dual-flow-path plate heat exchanger capable of changing flowing direction of heat exchange media twice

A technology of plate heat exchanger and heat exchange medium, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of waste of space, inconvenient arrangement of heat exchange pipes, etc., to ensure the heat exchange effect, Ease of popularization and utilization, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

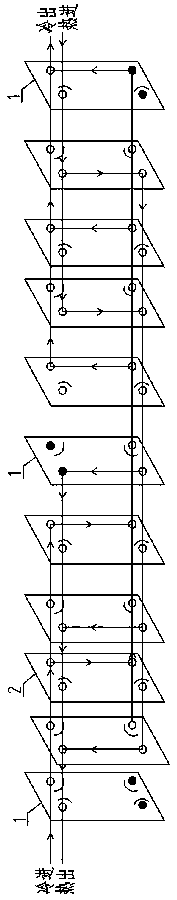

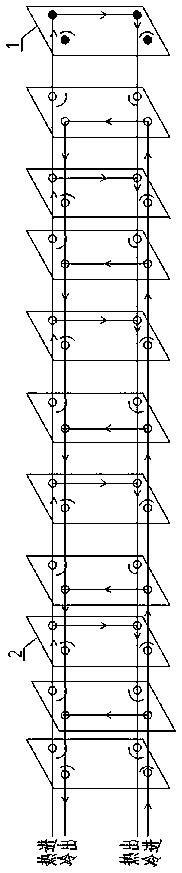

[0012] Such as figure 2 As shown, the channel layout of the heat exchange plates in the existing plate heat exchanger, in which the cold-side medium flows in from a through hole near the bottom of a heat exchange plate, and flows in the subsequent heat exchange plates It flows upwards, and finally flows out from the through hole near the top of the heat exchange plate that it flows into. On the contrary, the hot side medium flows in from the through hole near the top of the same heat exchange plate, and flows through the subsequent multiple heat exchange plates. It flows downward in the sheet, and finally flows out from the through hole near the bottom of the heat exchange plate it flows into. Due to this structure, the inlet and outlet pipelines of the cold-side medium and the hot-side medium will be cross-distributed relative to the heat exchange plates, which is not conducive to the reasonable layout of the on-site pipelines, and will cause inconvenience in the layout of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com