Inflammable liquid storage inherent danger evaluate method

A flammable liquid, dangerous technology, applied in the direction of instruments, data processing applications, resources, etc., can solve the problems of unsuitable safety distance, mixed storage, and inability to truly reflect hierarchical supervision, etc., to achieve the effect of reducing the overall risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

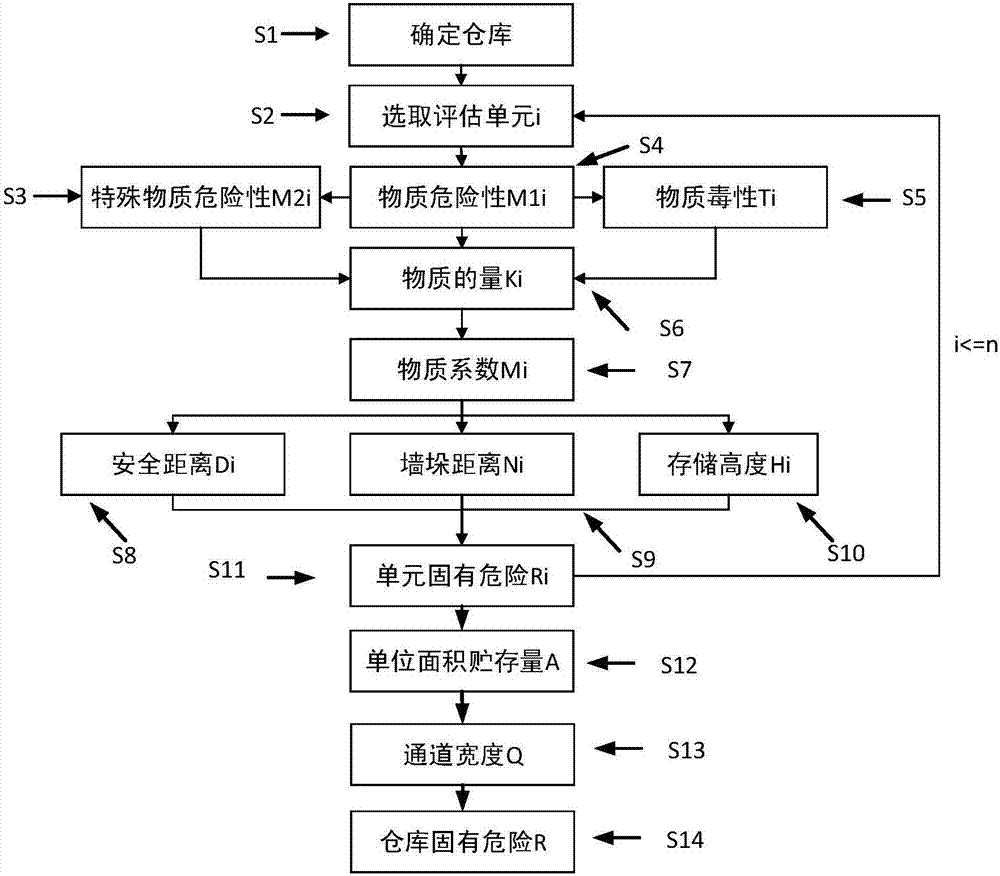

Method used

Image

Examples

Embodiment example

[0090] The inherent risk assessment method of flammable liquid storage provided by the present invention is to characterize the dangerous characteristics of hazardous chemical warehouses more specifically and accurately, and combine the safety Based on factors such as distance, chaotic stacking, diffusion of hazardous chemicals, and environmental conditions, the AHP is used to realize the inherent risk assessment of hazardous chemical storage. The specific implementation cases are as follows:

[0091] S1: Determine the warehouse: select a petrochemical enterprise 1000m 2 The hazardous chemicals warehouse stores gasoline, totaling 480t;

[0092] S2: Select evaluation unit i: the gasoline stored in the warehouse is divided into 80 units;

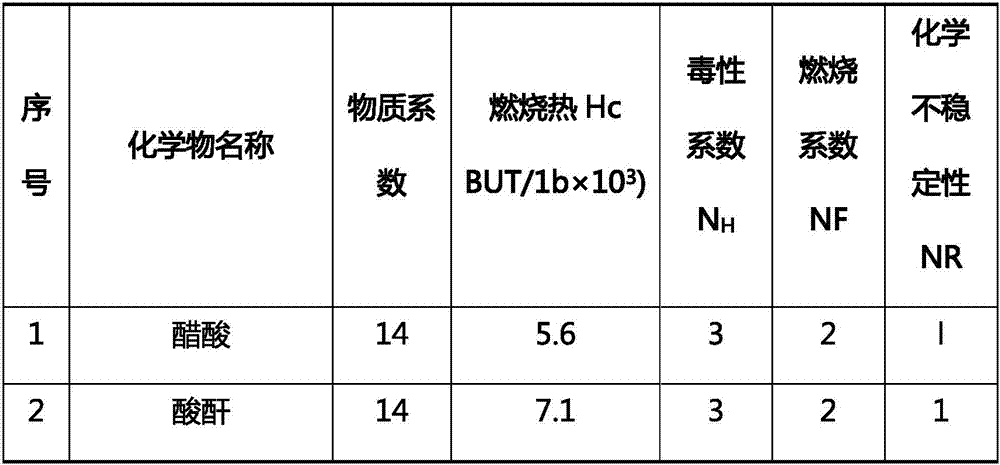

[0093] S3: Substance hazard M1i, i={0, 1, ---n}, where n is the maximum number of substance units, where n=80: Refer to Attached Table 1, gasoline substance hazard is 16;

[0094] S4: special substance hazard M2i, i={0, 1, ---n}, where n is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com