Main transformer cooling device

A technology of cooling device and main transformer, applied in transformer/inductor casing, transformer/inductor cooling, transformer/inductor components, etc., can solve problems such as poor cooling effect, single cooling method, transformer damage, etc., to achieve Prevent damage to the main body of the transformer, quickly cool down and dissipate heat, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

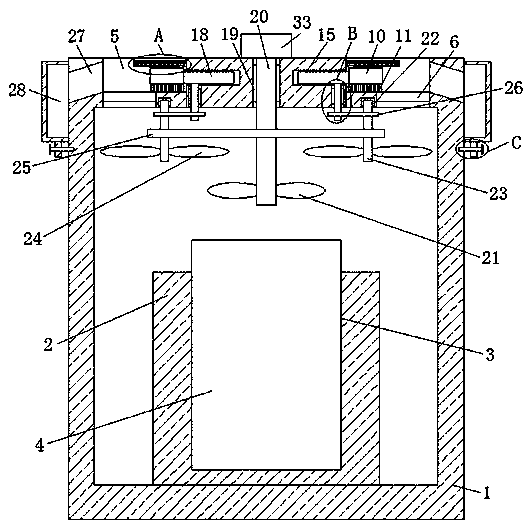

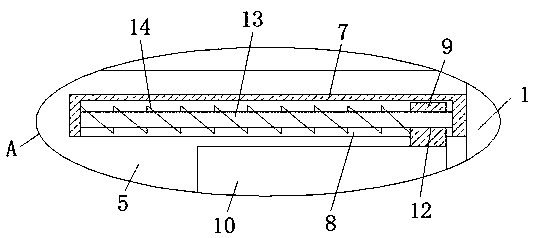

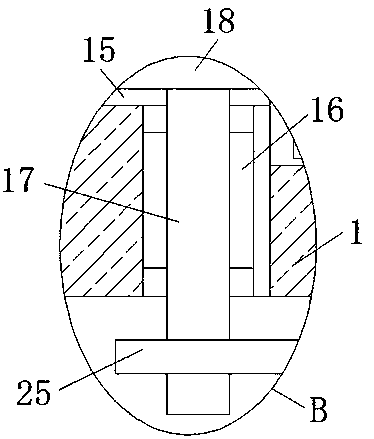

[0028] refer to Figure 1-5 , a cooling device for a main transformer, comprising a housing 1 set in a hollow structure, a mounting seat 2 is fixedly installed on the inner wall of the bottom of the housing 1, a placement groove 3 is opened on the top of the mounting seat 2, and a transformer is placed in the placement groove 3 The main body 4 and the top of the housing 1 are provided with two vents 5, the same dust-proof filter plate 6 is fixedly installed on the inner wall of both sides of the vent 5, and the inner wall of the side where the two vents 5 are close to each other is fixedly installed There are fixed plates 7, and the bottoms of the two fixed plates 7 are provided with chute 8, and sliders 9 are slidably installed in the two chute 8, and the bottom ends of the two sliders 9 respectively extend to the corresponding fixed plates 7 The bottom of the two brush plates 10 is fixedly installed with a brush plate 10, and the bottom ends of the two brush plates 10 are fi...

Embodiment 2

[0039] refer to Figure 1-5 , a cooling device for a main transformer, comprising a shell 1 set as a hollow structure, the bottom inner wall of the shell 1 is fixedly connected with a mounting base 2 by bolts, the top of the mounting base 2 is provided with a placement groove 3, and the placement groove 3 is placed There is a transformer main body 4, two vents 5 are opened on the top of the housing 1, the same dust-proof filter plate 6 is fixedly connected to the inner walls on both sides of the vents 5 by bolts, and the inner wall of the side where the two vents 5 are close to each other Both of them are fixedly connected with fixed plates 7 by bolts, and the bottoms of the two fixed plates 7 are provided with chute 8, and slide blocks 9 are slidably installed in the two chute 8, and the bottom ends of the two slide blocks 9 respectively extend to The bottom of the corresponding fixing plate 7 is fixedly connected with a brush plate 10 by bolts, and the bottom ends of the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com