Intelligent electric tool charging maintenance device

A technology for power tools and maintenance devices, applied in battery circuit devices, circuit devices, electric vehicles, etc., can solve the problems of reduced battery life, battery explosion, insufficient power, etc., to improve reliability, prolong service life, charge and store normative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

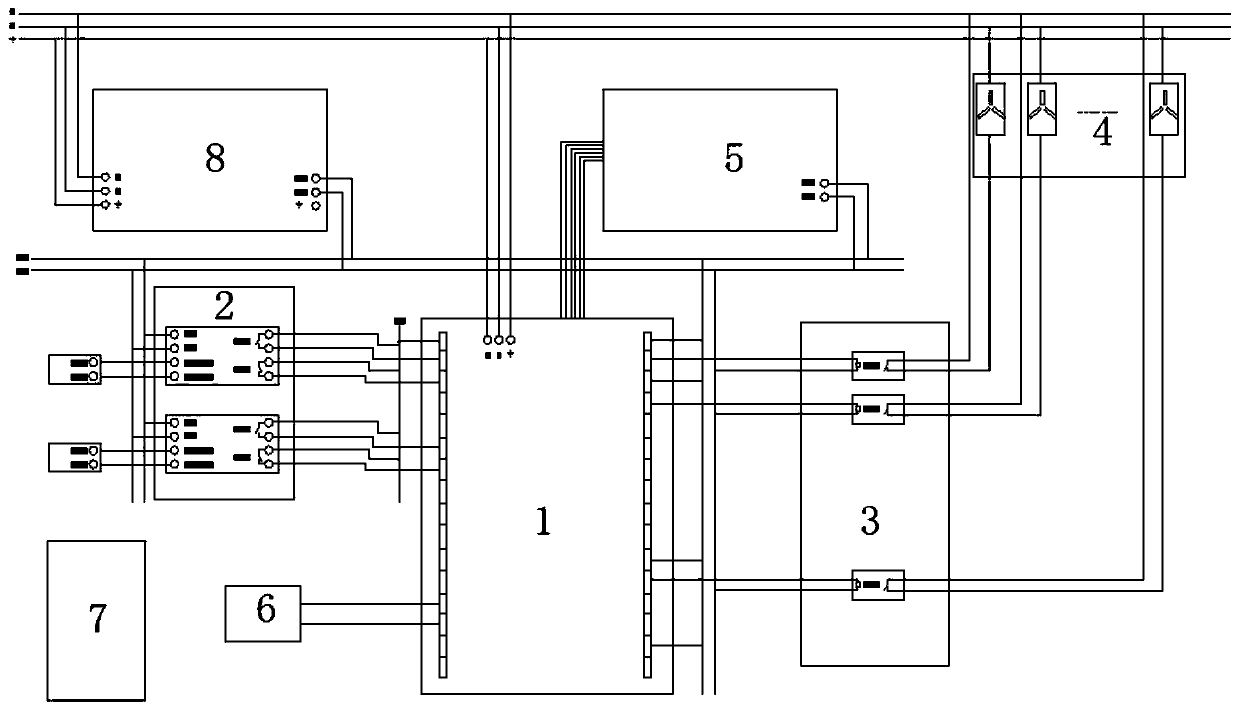

[0021] The present invention provides an intelligent electric tool charging and maintenance device, characterized in that: the intelligent electric tool charging and maintenance device includes a PLC module 1, a voltage acquisition module 2, a control module 3, a power strip 4, a display 5, Remote transmission module 6, remote terminal 7, power supply module 8;

[0022] Among them: the PLC module 1 is a programmable controller with a programming interface, the input terminal of the PLC module 1 is connected to the voltage acquisition module 2, the output terminal of the PLC module 1 is connected to multiple control modules 3, and each control module 3 is connected to a socket 4, the PLC The video signal end of the module 1 is connected to the display 5, the PLC module 1 is connected to the remote transmission module 6, the remote transmission module 6 can directly interact with the remote terminal 7, and the power supply module 8 is connected to the PLC module 1, the voltage ac...

Embodiment 2

[0034] The present invention provides an intelligent electric tool charging and maintenance device, characterized in that: the intelligent electric tool charging and maintenance device includes a PLC module 1, a voltage acquisition module 2, a control module 3, a power strip 4, a display 5, Remote transmission module 6, remote terminal 7, power supply module 8;

[0035] Among them: the PLC module 1 is a programmable controller with a programming interface, the input terminal of the PLC module 1 is connected to the voltage acquisition module 2, the output terminal of the PLC module 1 is connected to multiple control modules 3, and each control module 3 is connected to a socket 4, the PLC The video signal end of the module 1 is connected to the display 5, the PLC module 1 is connected to the remote transmission module 6, the remote transmission module 6 can directly interact with the remote terminal 7, and the power supply module 8 is connected to the PLC module 1, the voltage ac...

Embodiment 3

[0045] The present invention provides an intelligent electric tool charging and maintenance device, characterized in that: the intelligent electric tool charging and maintenance device includes a PLC module 1, a voltage acquisition module 2, a control module 3, a power strip 4, a display 5, Remote transmission module 6, remote terminal 7, power supply module 8;

[0046] Among them: the PLC module 1 is a programmable controller with a programming interface, the input terminal of the PLC module 1 is connected to the voltage acquisition module 2, the output terminal of the PLC module 1 is connected to multiple control modules 3, and each control module 3 is connected to a socket 4, the PLC The video signal end of the module 1 is connected to the display 5, the PLC module 1 is connected to the remote transmission module 6, the remote transmission module 6 can directly interact with the remote terminal 7, and the power supply module 8 is connected to the PLC module 1, the voltage ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com