Tuber mustard harvester

A harvester and mustard technology, applied in harvesters, agricultural machinery and tools, planting methods, etc., can solve problems such as hard work and low efficiency, and achieve the effect of compact overall structure, flexible action and good reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

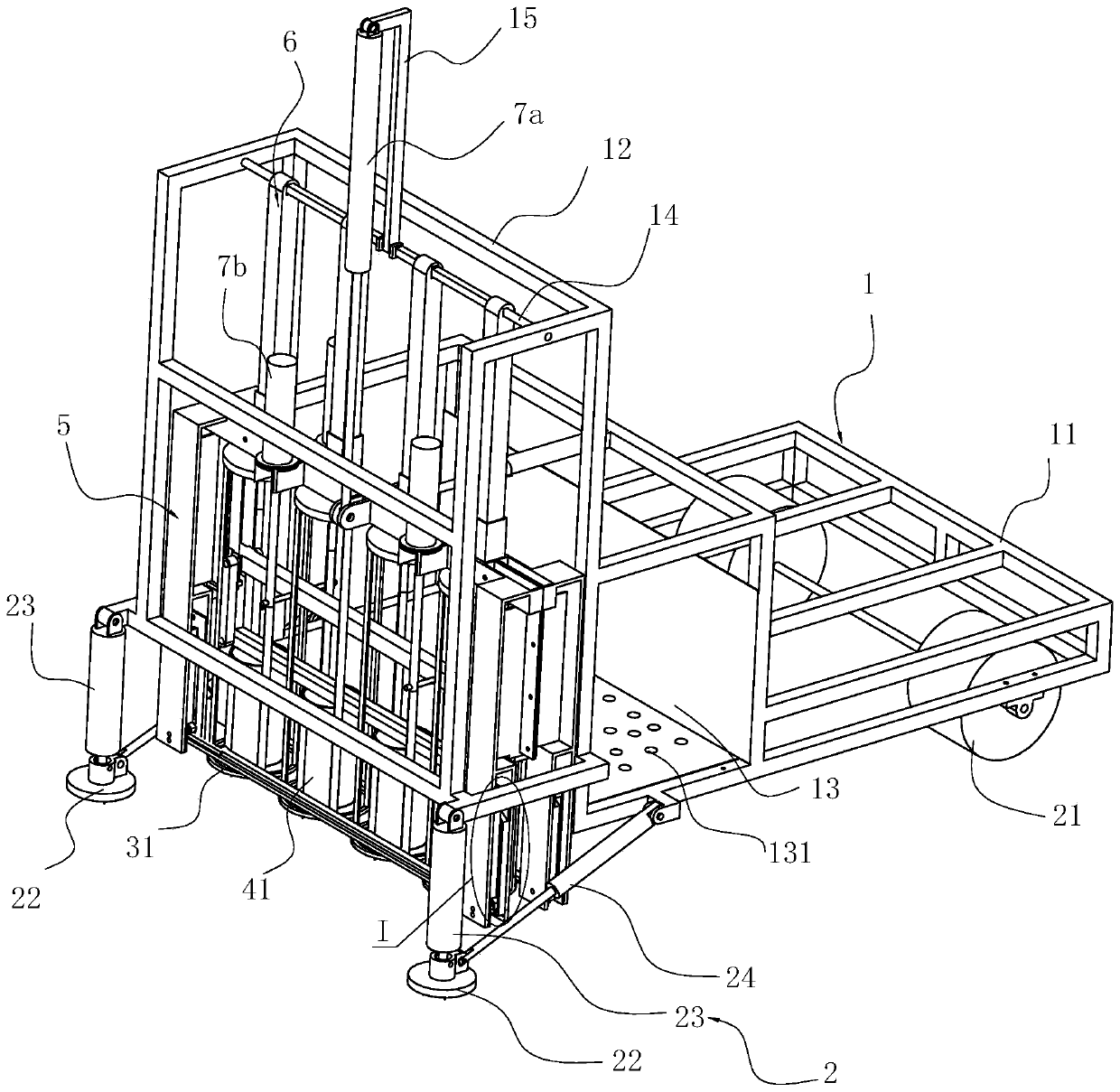

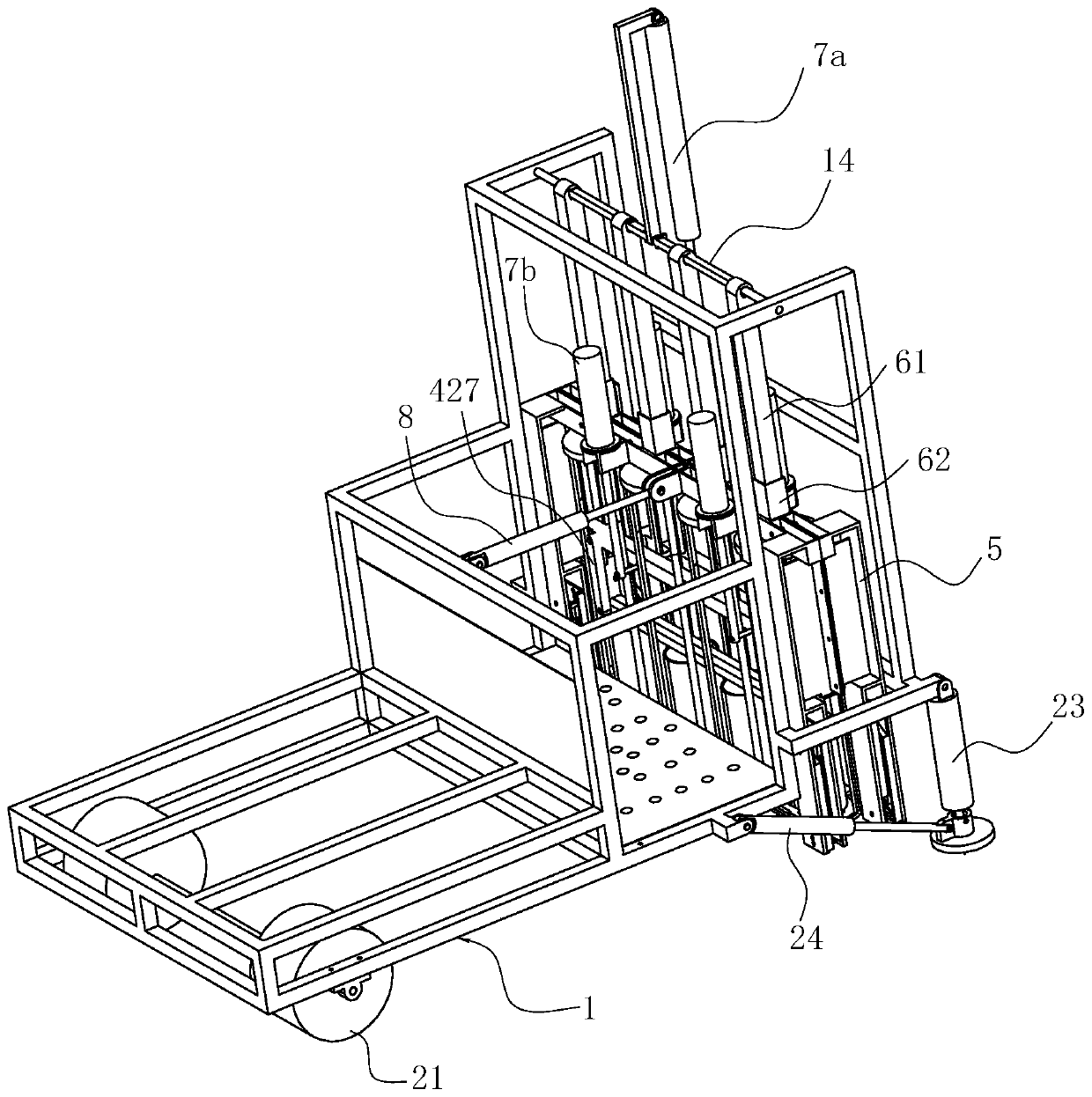

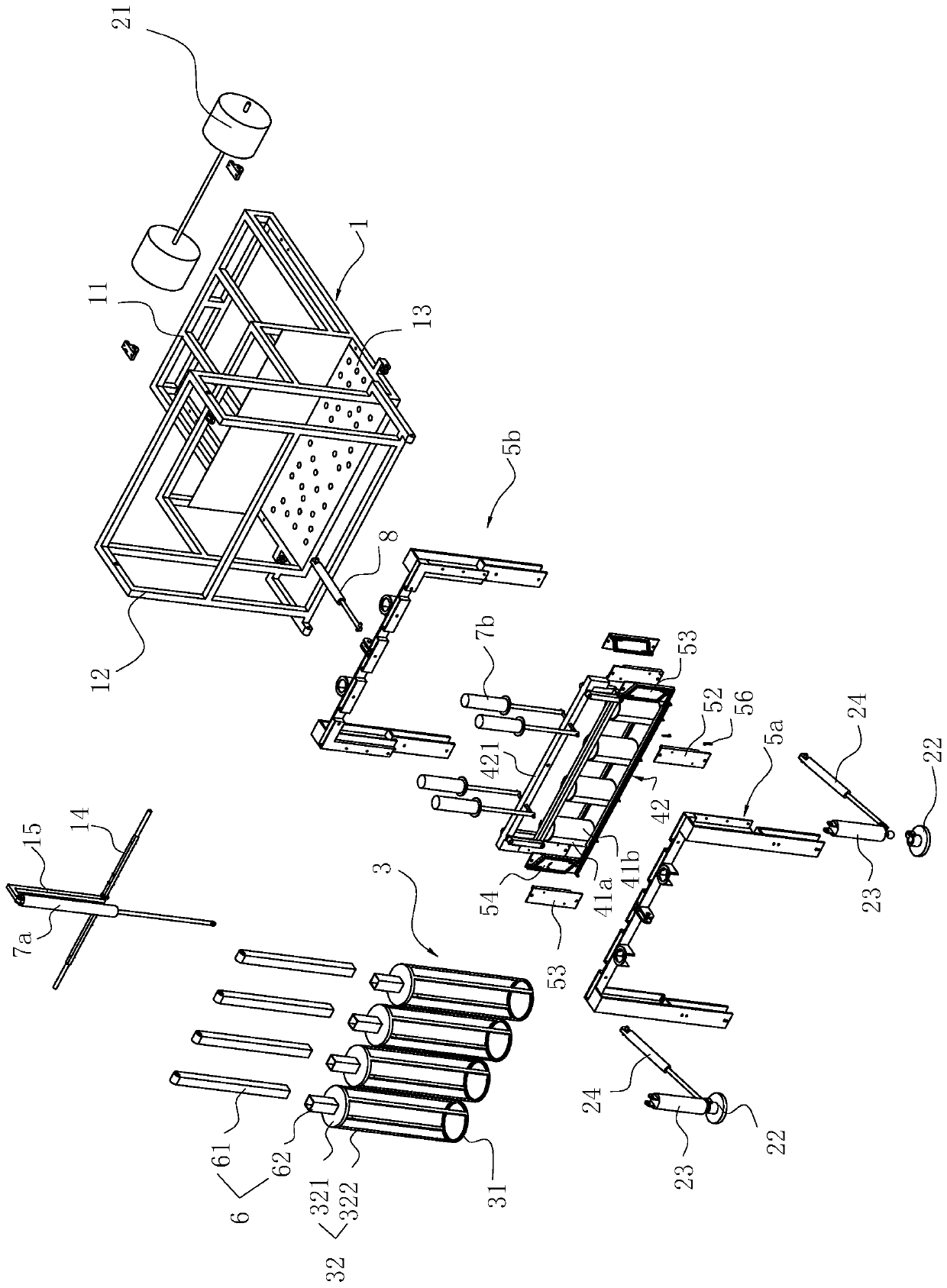

[0031] like Figure 1 to Figure 9 As shown, the mustard harvester includes a fuselage 1, a traveling mechanism 2 positioned under the fuselage, a vegetable leaf removal mechanism 3 positioned at the front of the fuselage, and a vegetable head clamping and conveying mechanism capable of cutting vegetable roots and accommodating or releasing the vegetable head. Mechanism 4, wherein the fuselage 1 includes a base 11, an upright frame 12 located at the front of the base, and a storage box 13 adjacent to the frame for storing vegetable heads. The bottom of the storage box 13 is provided with a plurality of soil falling holes 131. A rotating shaft 14 is rotatably arranged on the top of the frame body 12, and a pedestal 5 positioned below the rotating shaft stands upright in the frame body 12. In this embodiment, the pedestal 5 is spliced and asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com