mustard harvester

A harvester and pickled mustard technology, which is applied to harvesters, agricultural machinery and tools, and digging/covering ditches and holes, etc., can solve the problems of hard work and low efficiency, and achieve the effect of compact structure, flexible movement and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

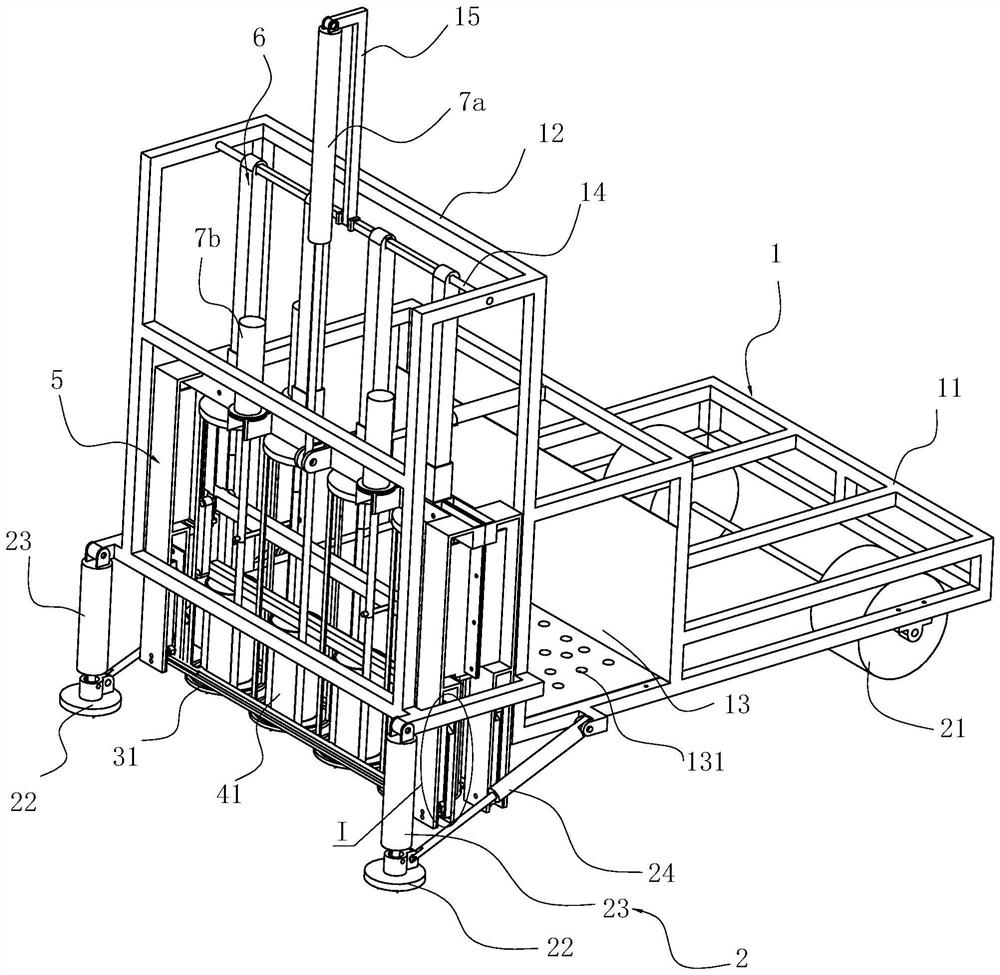

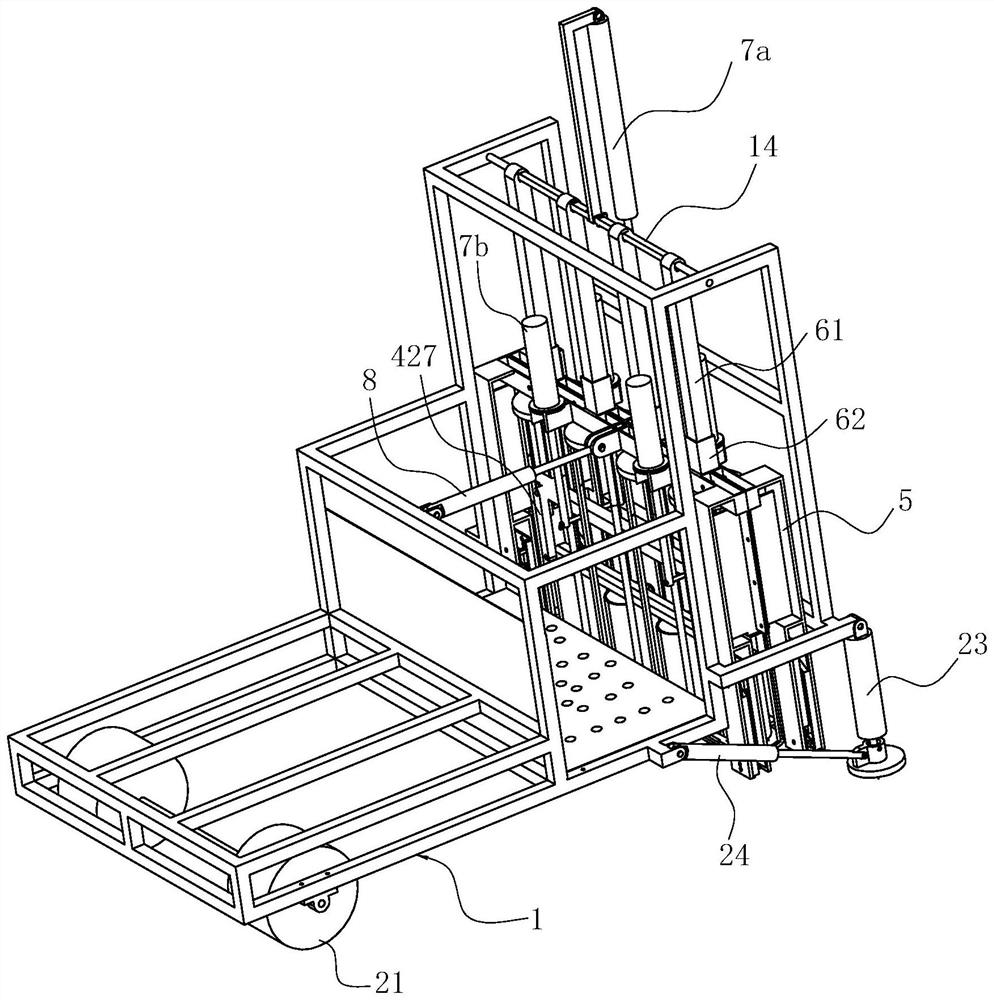

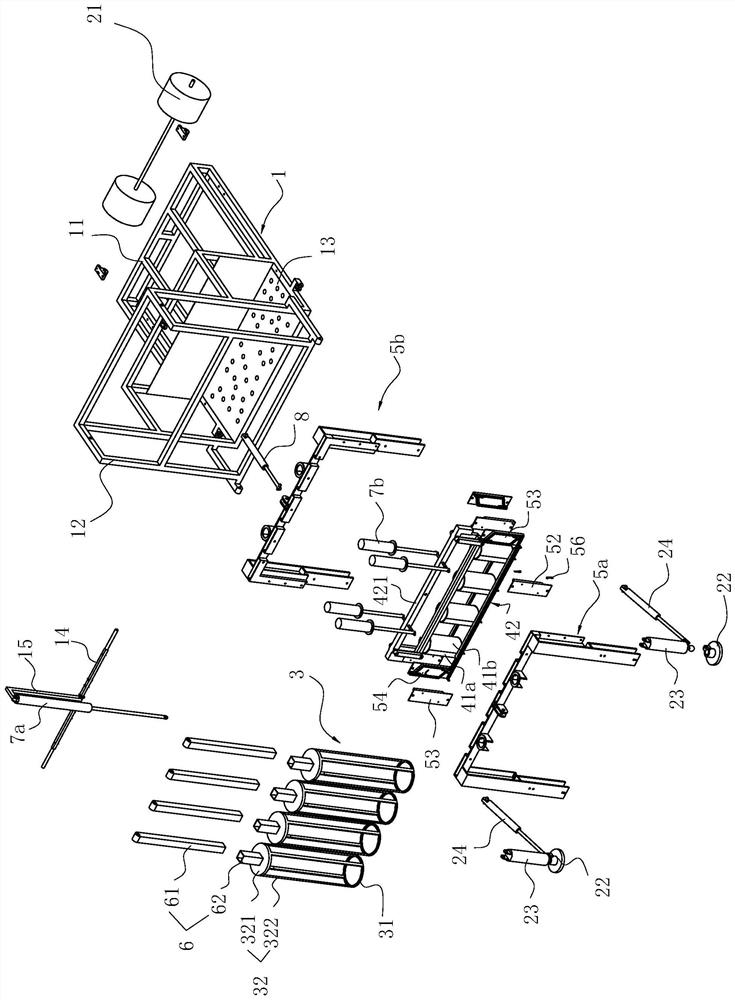

[0031] Such as Figure 1 to Figure 9 As shown, the mustard harvester includes a fuselage 1, a traveling mechanism 2 positioned under the fuselage, a vegetable leaf removal mechanism 3 positioned at the front of the fuselage, and a vegetable head clamping and conveying mechanism capable of cutting vegetable roots and accommodating or releasing the vegetable head. Mechanism 4, wherein the fuselage 1 includes a base 11, an upright frame 12 located at the front of the base, and a storage box 13 adjacent to the frame for storing vegetable heads. The bottom of the storage box 13 is provided with a plurality of soil falling holes 131. A rotating shaft 14 is rotatably arranged on the top of the frame body 12, and a pedestal 5 positioned below the rotating shaft stands upright in the frame body 12. In this embodiment, the pedestal 5 is spliced and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com