A forming method of stainless steel upsetting products

A stainless steel and upsetting technology, which is applied in the field of forming methods of stainless steel upsetting products, can solve the problems of inability to realize mass production, reduce product processing quality, and difficult to ensure processing quality, and achieves improvement of upsetting quality, upsetting efficiency, The effect of improving the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

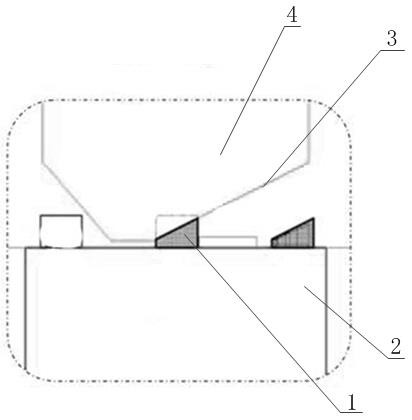

[0020] Such as Figure 3~4 shown. A forming method for stainless steel upsetting products, which comprises the following steps:

[0021] S1. Upset forming of semi-finished wedges:

[0022] S11. Arranging the stainless steel blank blocks 1 on the material frame along a straight line to form a strip, and tooling the stainless steel blank block 1 at the head end of the strip on the top surface of the upsetting die 2;

[0023] S12, control the start of the punching machine, the punching machine drives the punch and the upsetting punch 4 below it to move downward, the slope 3 of the upsetting punch 4 is pressed on the top of the stainless steel blank block 1, and the top of the stainless steel blank block 1 is formed and The inclined surface matched with the inclined surface 3, thereby obtaining the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com