Comprehensive balance discharge adjustment method for parallel tank propulsion system

A technology of comprehensive balance and adjustment methods, which is applied in the directions of propulsion system devices, control/regulation systems, and space navigation equipment of space navigation vehicles. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

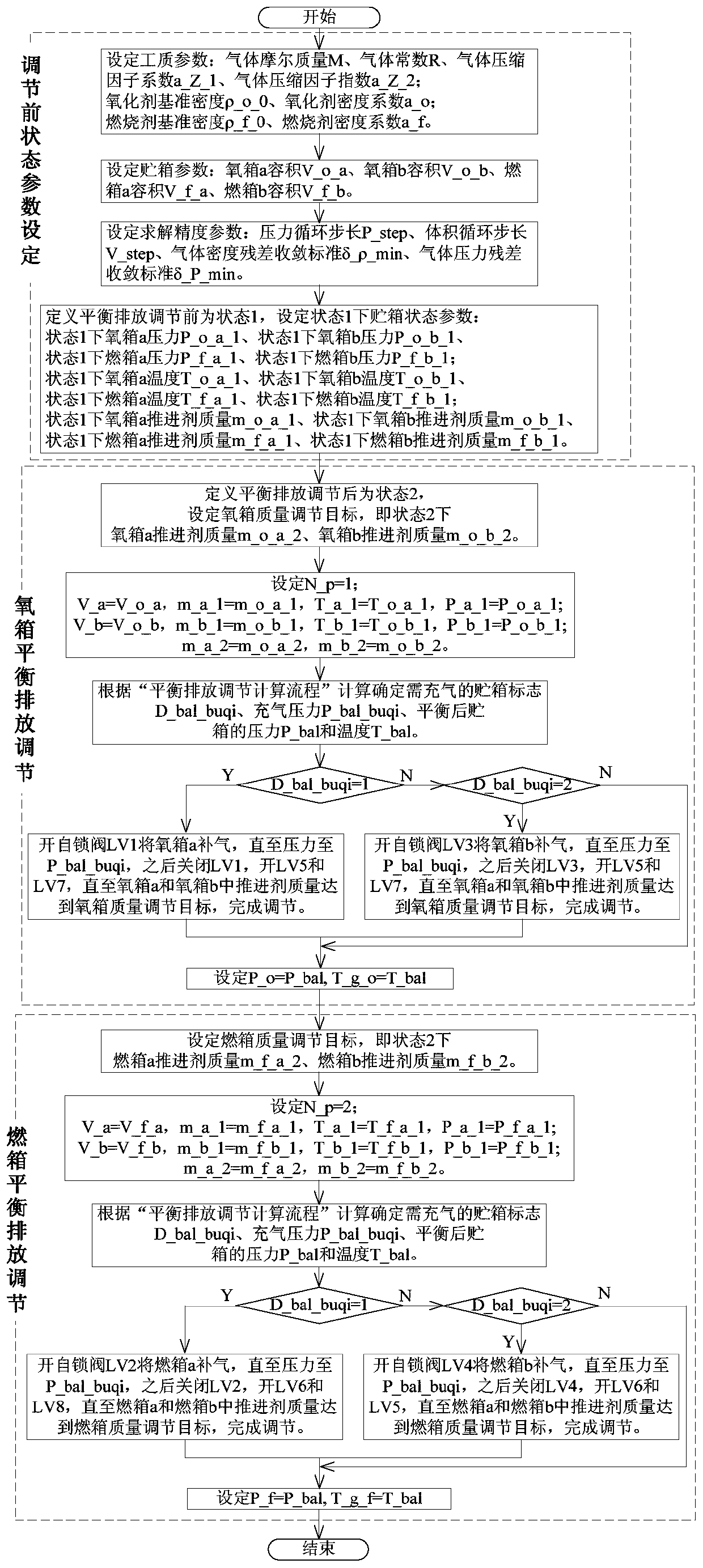

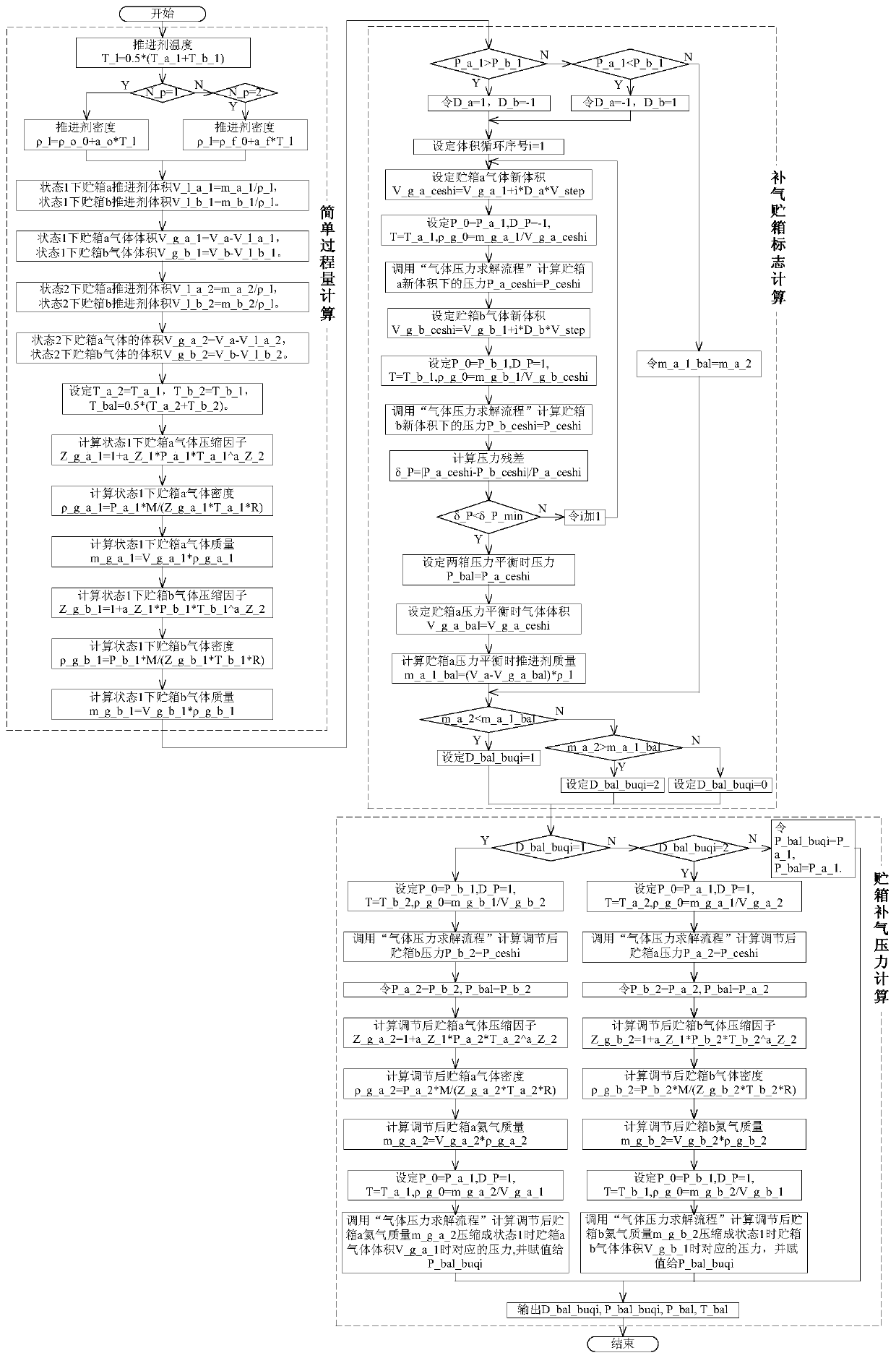

[0115] The present invention will be described in further detail below in conjunction with the accompanying drawings.

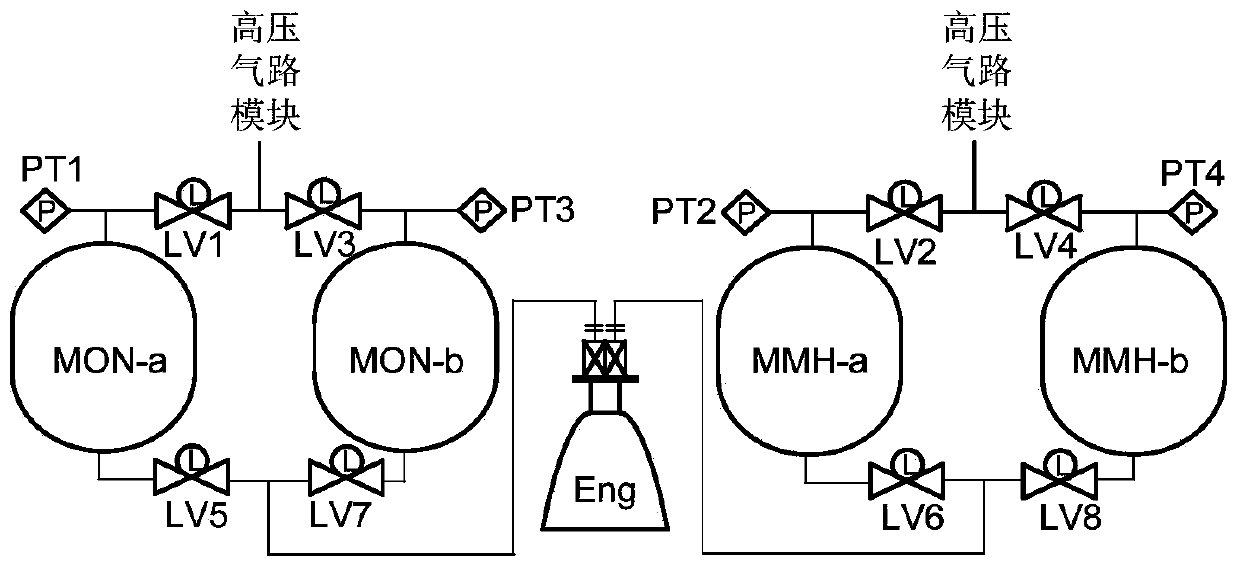

[0116] Such as figure 1 As shown, the spacecraft parallel storage tank chemical propulsion system generally includes 4 storage tanks, including 2 oxygen tanks and 2 fuel tanks, which are oxygen tank a MON-a, oxygen tank b MON-b, fuel tank a MMH- a. Fuel tank b MMH-b. The oxidant is discharged in parallel between the two oxygen tanks, that is, the downstream propellant outlets of oxygen tank a MON-a and oxygen tank b MON-b are respectively provided with self-locking valves LV5 and LV7 downstream of the storage tanks, and then connected together, and lead to the engine Eng An oxidant inlet to supply oxidant to the engine Eng. The upstream gas inlets of oxygen tank aMON-a and oxygen tank b MON-b are respectively provided with upstream self-locking valves LV1 and LV3 of the storage tanks, and then communicated together.

[0117] The combustion agent is dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com