Automatic sorting and replenishment method and system

An automatic sorting and replenishment method technology, applied in the direction of transportation, packaging, storage devices, etc., can solve the problems of shipping errors, waste of human resources, sorting errors, etc., and achieve the effect of avoiding manual sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

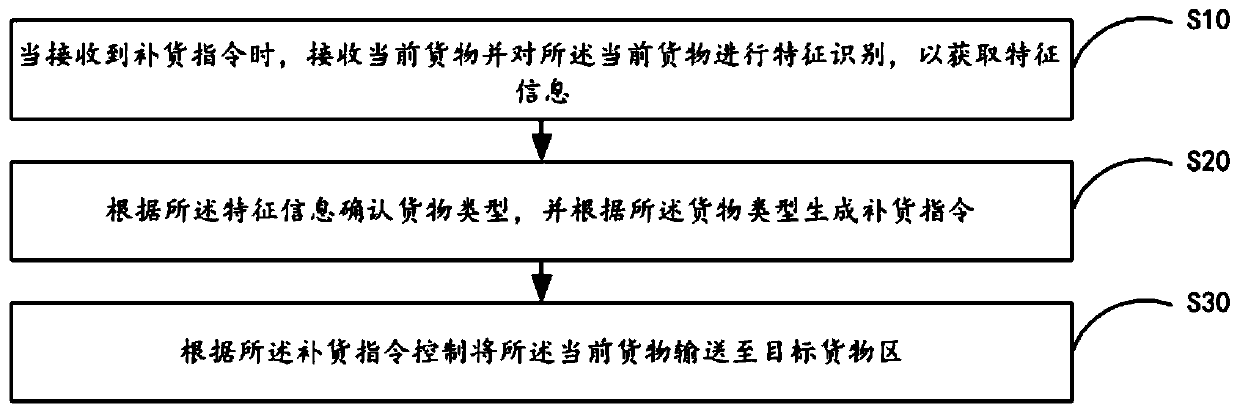

[0043] see figure 1 , is a schematic flow chart of the automatic sorting and replenishment method provided by the first embodiment of the present invention, including steps:

[0044] Step S10, when a replenishment instruction is received, receive the current goods and perform feature recognition on the current goods to obtain feature information;

[0045] Wherein, the replenishment instruction is transmitted in the form of voice instruction, button instruction or wireless instruction, and the replenishment instruction can be triggered manually by the user, and can also be triggered in an automatic way, that is, by automatically judging the Whether replenishment is needed, and when it is judged that replenishment is required, the replenishment instruction is automatically sent; specifically, in this embodiment, the characteristic information can be color features, image features, text features, etc., and each type of commodity All correspond to unique characteristic informatio...

Embodiment 2

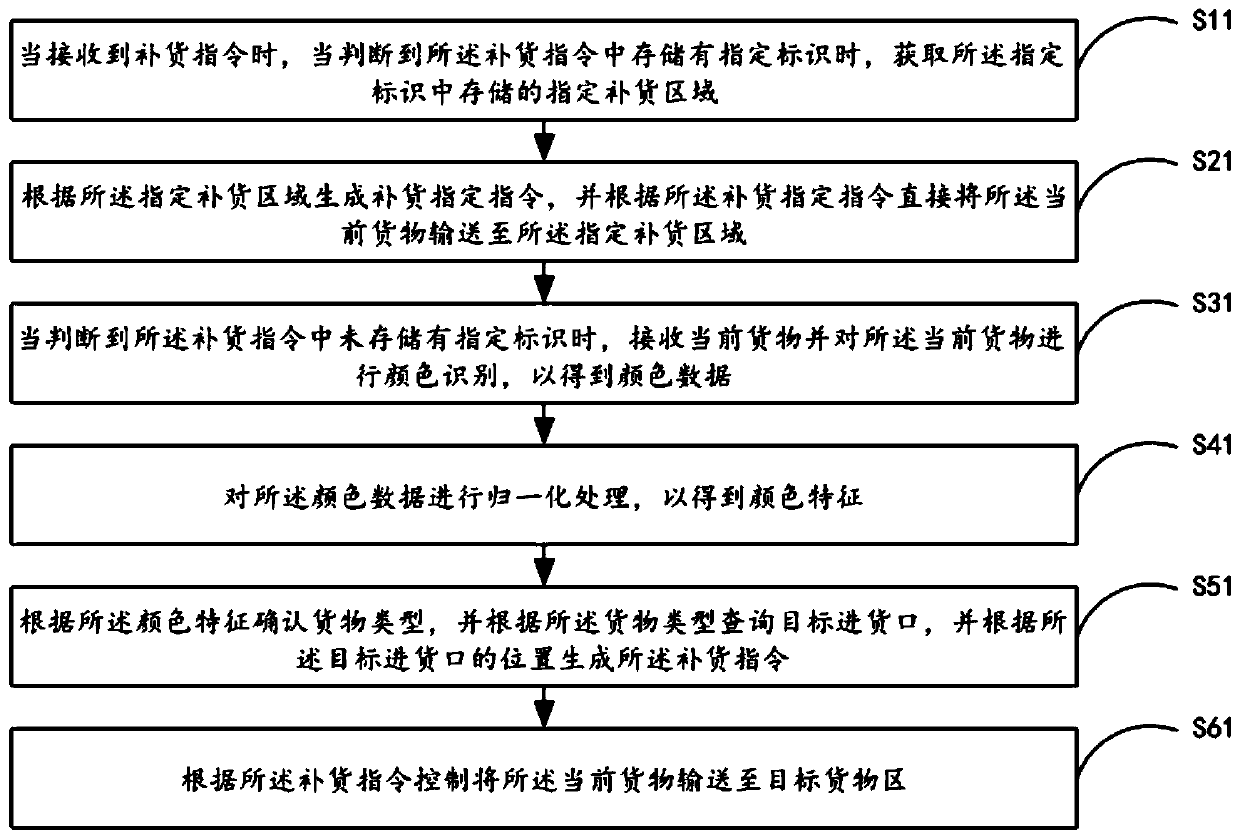

[0055] see figure 2 , is a schematic flow chart of the automatic sorting and replenishment method provided by the second embodiment of the present invention, including steps:

[0056] Step S11, receiving a replenishment instruction, and when it is determined that a designated identifier is stored in the replenishment instruction, acquire the designated replenishment area stored in the designated identifier;

[0057] Wherein, the designated identification can be stored in the replenishment instruction by means of text identification or image identification, etc., and when it is judged that the designated instruction is stored, it is determined that the user currently needs to transport the current goods to the designated area;

[0058] Step S21, generating a designated replenishment instruction according to the designated replenishment area, and directly transporting the current goods to the designated replenishment area according to the designated replenishment instruction; ...

Embodiment 3

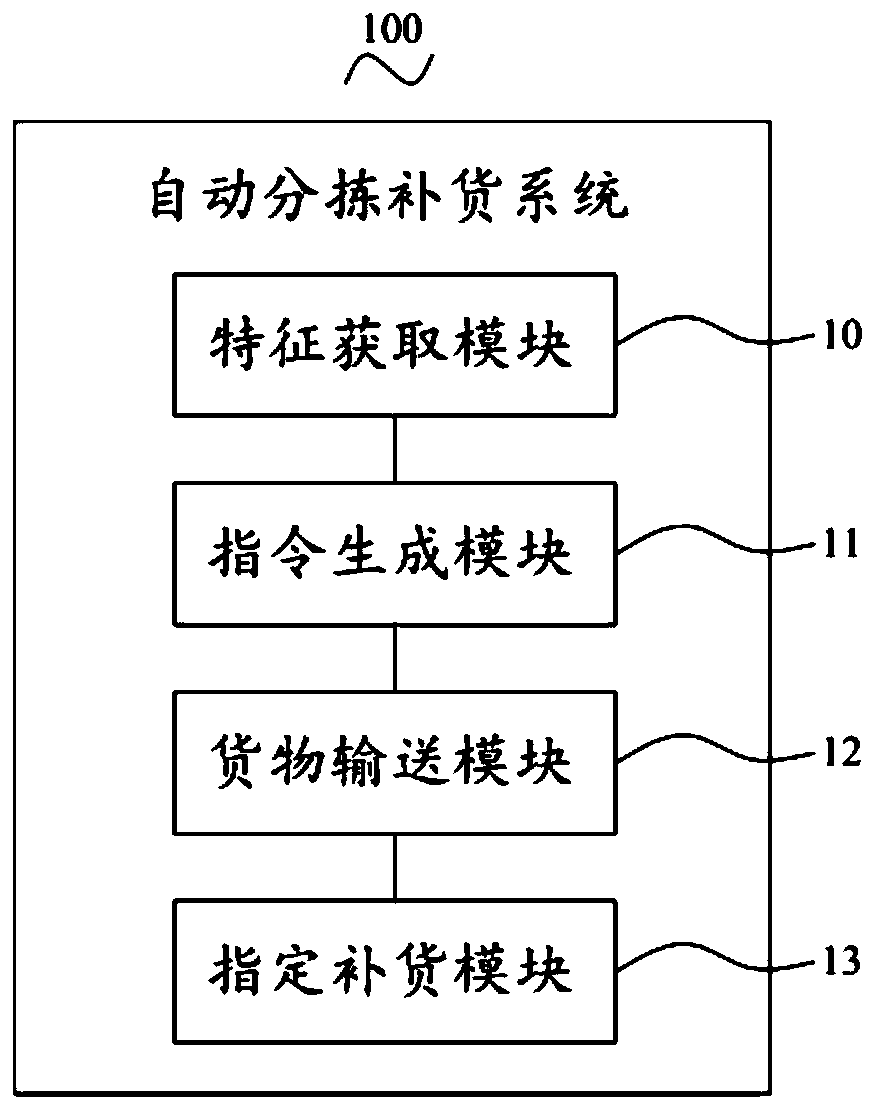

[0090] see image 3 , is a schematic structural diagram of the automatic sorting and replenishment system 100 provided by the third embodiment of the present invention, including: a feature acquisition module 10, an instruction generation module 11 and a cargo delivery module 12, wherein:

[0091] The feature acquisition module 10 is configured to receive the current goods and perform feature recognition on the current goods to obtain feature information when receiving a replenishment instruction, wherein the replenishment instruction adopts a voice command, a button command or a wireless command and the replenishment instruction can be triggered manually by the user, or it can be triggered in an automatic way, that is, by automatically judging whether various commodities need to be replenished, and when it is judged that replenishment is required, automatically send the Specifically, in this embodiment, the feature information can be color features, image features, text featu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com