Asynchronous door knife assembly of elevator car door lock

A door knife and component technology, which is used in elevators, transportation and packaging in buildings, etc., can solve problems such as car doors not being able to be opened and people closing accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

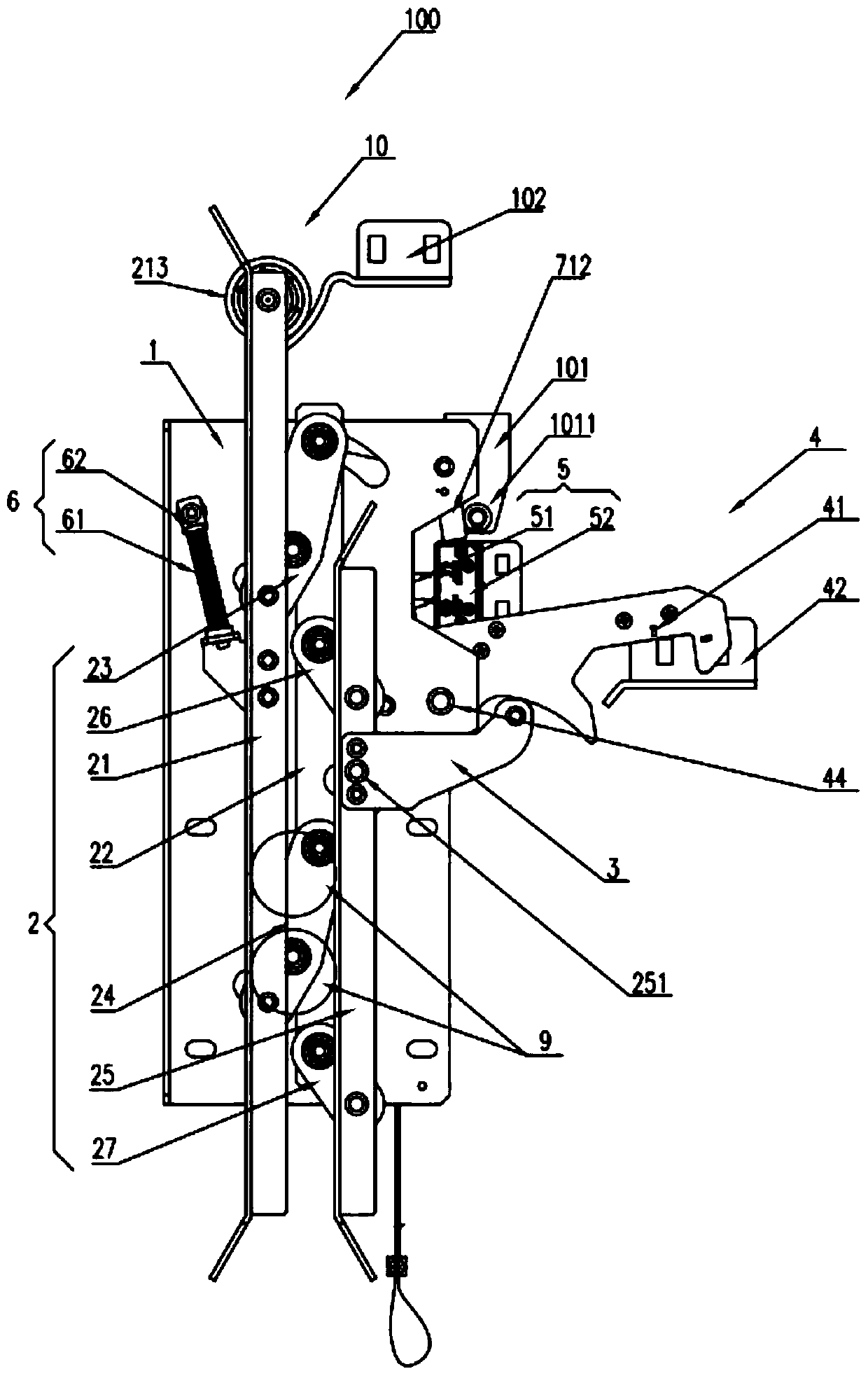

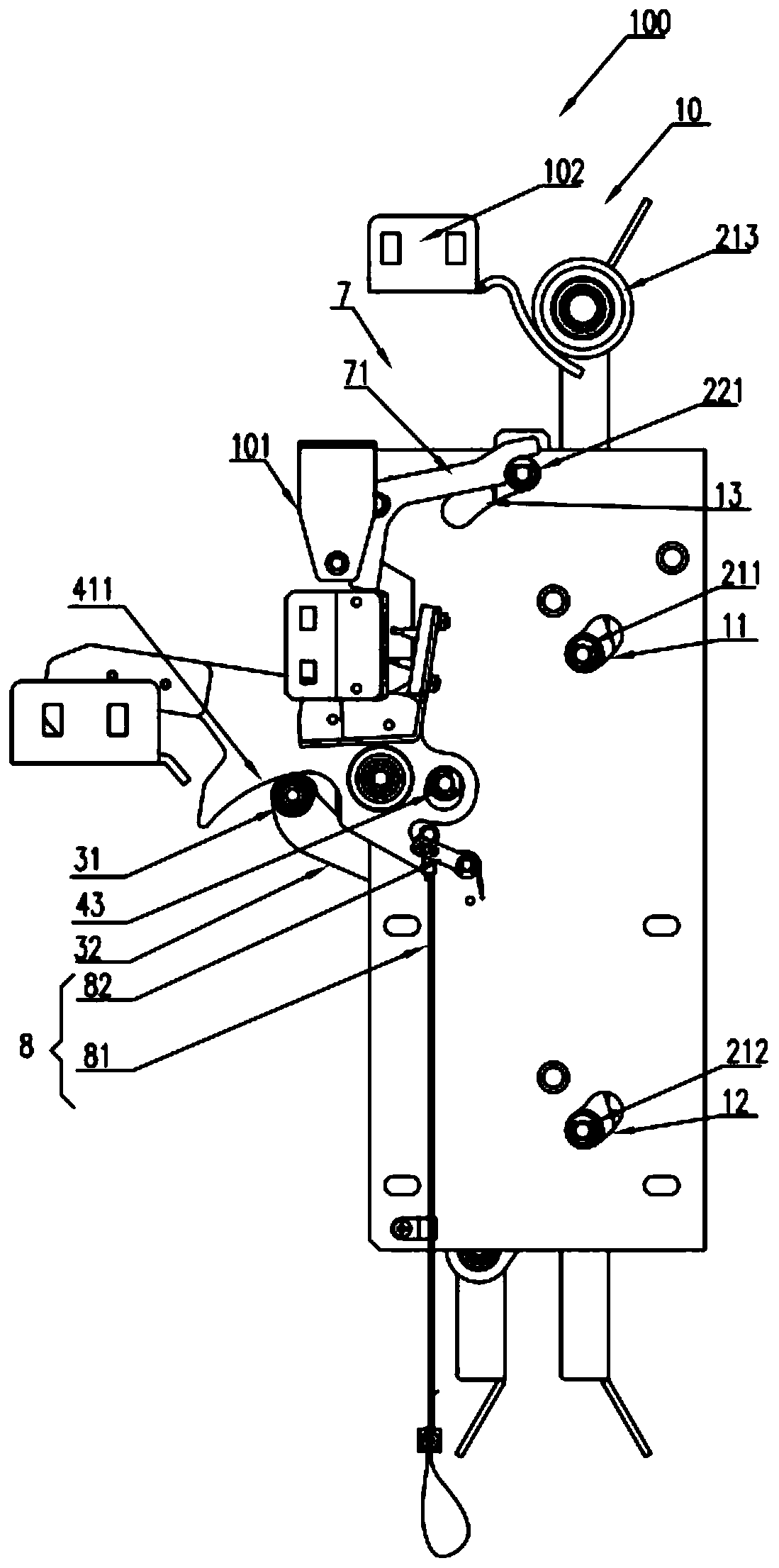

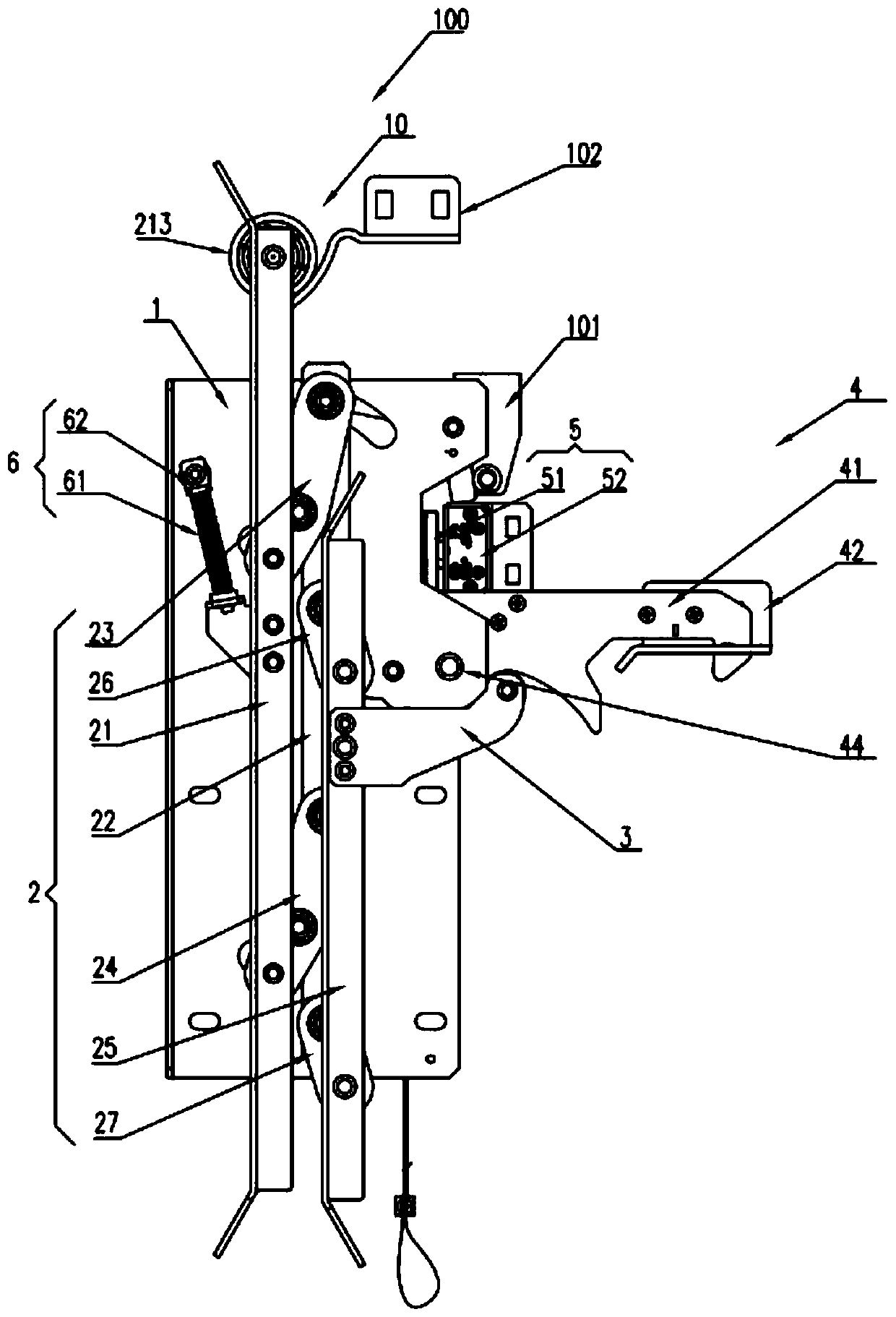

[0045] As a first example, such as Figure 1 to Figure 13 As shown, an elevator car door lock asynchronous door knife assembly 100 includes: door knife back plate 1, knife arm link assembly 2, unlocking assembly 3, lock hook assembly 4, car door lock assembly 5, spring return assembly 6, limiter Position and reset component 7 and manual unlocking component 8.

[0046] Knife arm linkage assembly 2 includes: left knife arm 21, right knife arm 25, synchronous connecting plate 22, door knife upper link 23, door knife lower link 24, right knife arm upper swing link 26 and right knife arm lower swing link 27. The synchronous connecting plate 22, the upper swing link 26 of the right knife arm, the right knife arm 25 and the lower swing link 27 of the right knife arm are mutually hinged to form a parallelogram linkage. The synchronous connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com