Floating slab track structure based on external hydraulic type inerters and internal hydraulic type inerters

A technology of inerters and floating plates, which is applied in the field of rail applications, can solve the problems of poor low-frequency vibration reduction, high requirements for liquid damping material composition, and low utilization rate of damping energy consumption, and achieve the goal of expanding the range and improving the vibration isolation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

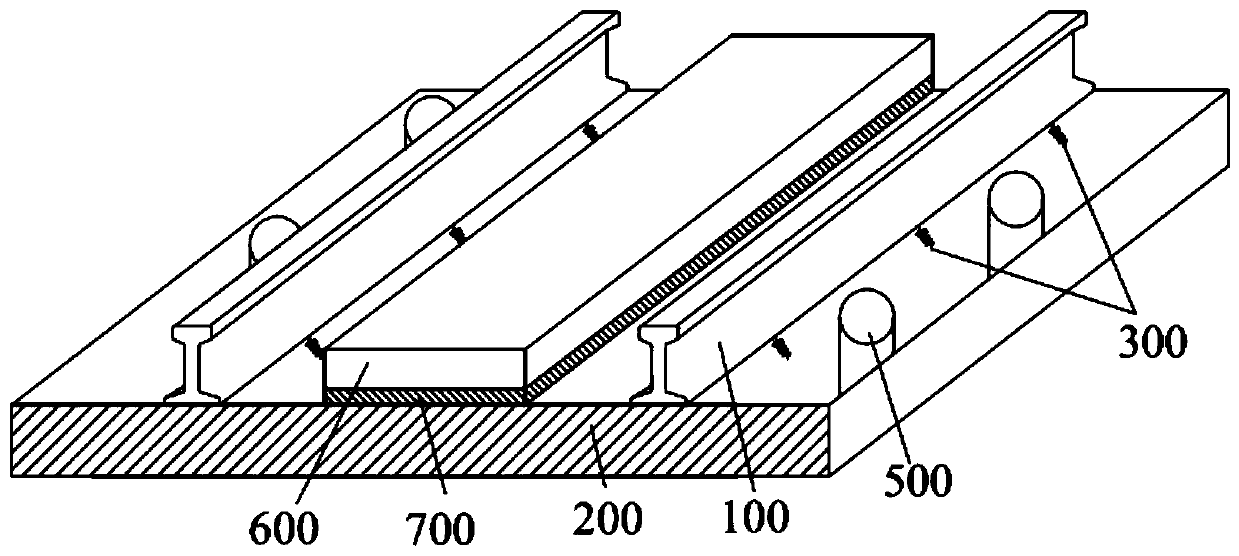

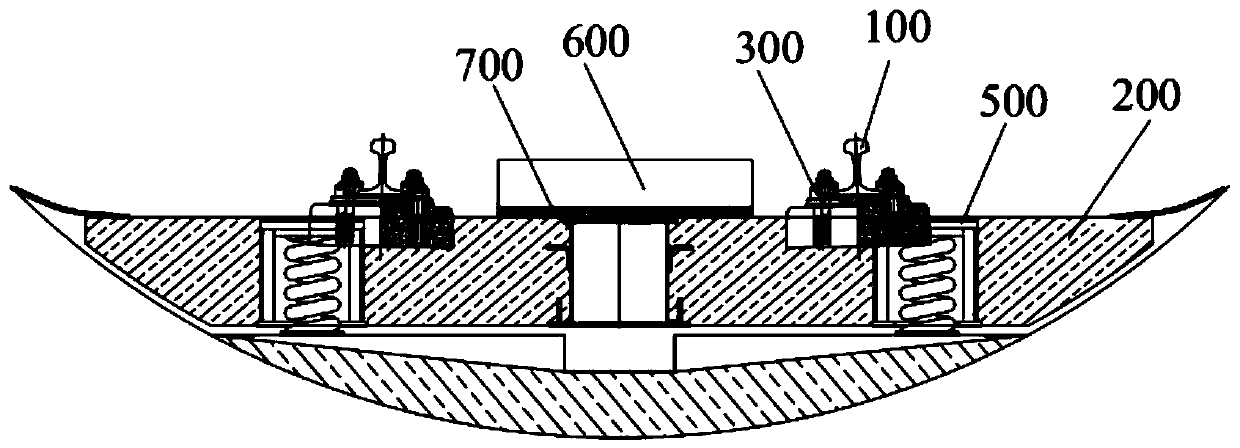

[0033] See Figure 1 to Figure 5 ;Such as figure 1 and figure 2 As shown, this embodiment provides a floating slab track structure based on an external hydraulic inerter, including: a steel rail 100, a track plate 200, a fastener 300, a horizontal limit device (not shown), and a shear hinge (not shown), vibration isolator 500, weight-increasing boss 600 and elastic element 700; wherein, the track plate 200 is arranged below the rail 100, and the track plate 200 and the rail 100 pass through the The fastener 300 is fixedly connected; the horizontal limiting device is arranged on both sides of the track plate 200, and can be used to limit the horizontal position of the track plate 200; the shear hinge is used to place the track The plate 200 is connected to another track plate 200, so that multiple track plates 200 are connected as a whole; the vibration isolator 500 is arranged inside the track plate 200, and is located on the outside or inside of the lower surface of the ra...

Embodiment 2

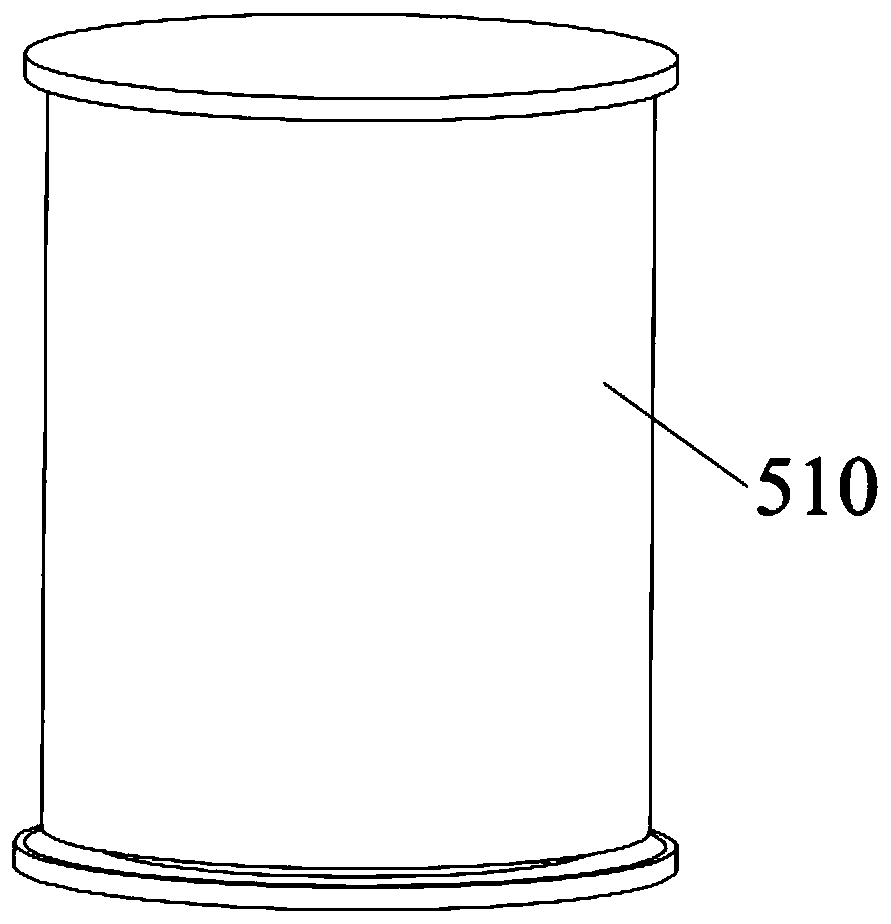

[0052] See figure 1 , figure 2 , image 3 as well as Figure 7 , this embodiment provides a floating plate track structure based on a built-in hydraulic inertial container; the difference from the first embodiment above is that in this embodiment, a built-in hydraulic inertial container (not marked); wherein, the built-in hydraulic inerter includes an elongated spiral tube 530 , a liquid damper (not shown) and a helical steel spring 540 .

[0053] The elongated spiral tube 530 is arranged inside the inner cylinder 520, and the elongated spiral tube 530 is coiled on the inner wall of the inner cylinder 520, and is fixedly connected with the inner cylinder 520; the liquid damping seal is inside the inner cylinder 520 The inside of the inner tube 520; the coiled steel spring 540 is arranged inside the inner tube 520, and the coiled steel spring 540 is embedded in the inner tube 520, and the bottom of the coiled steel spring 540 is in contact with the inner tube 520. The bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com