Civil engineering composite pile

A technology for civil engineering and composite piles, which is applied in basic structure engineering, sheet pile walls, buildings, etc., can solve problems such as easy deformation, construction errors, and instability, achieve low accuracy requirements, reduce construction difficulty, and reduce The effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

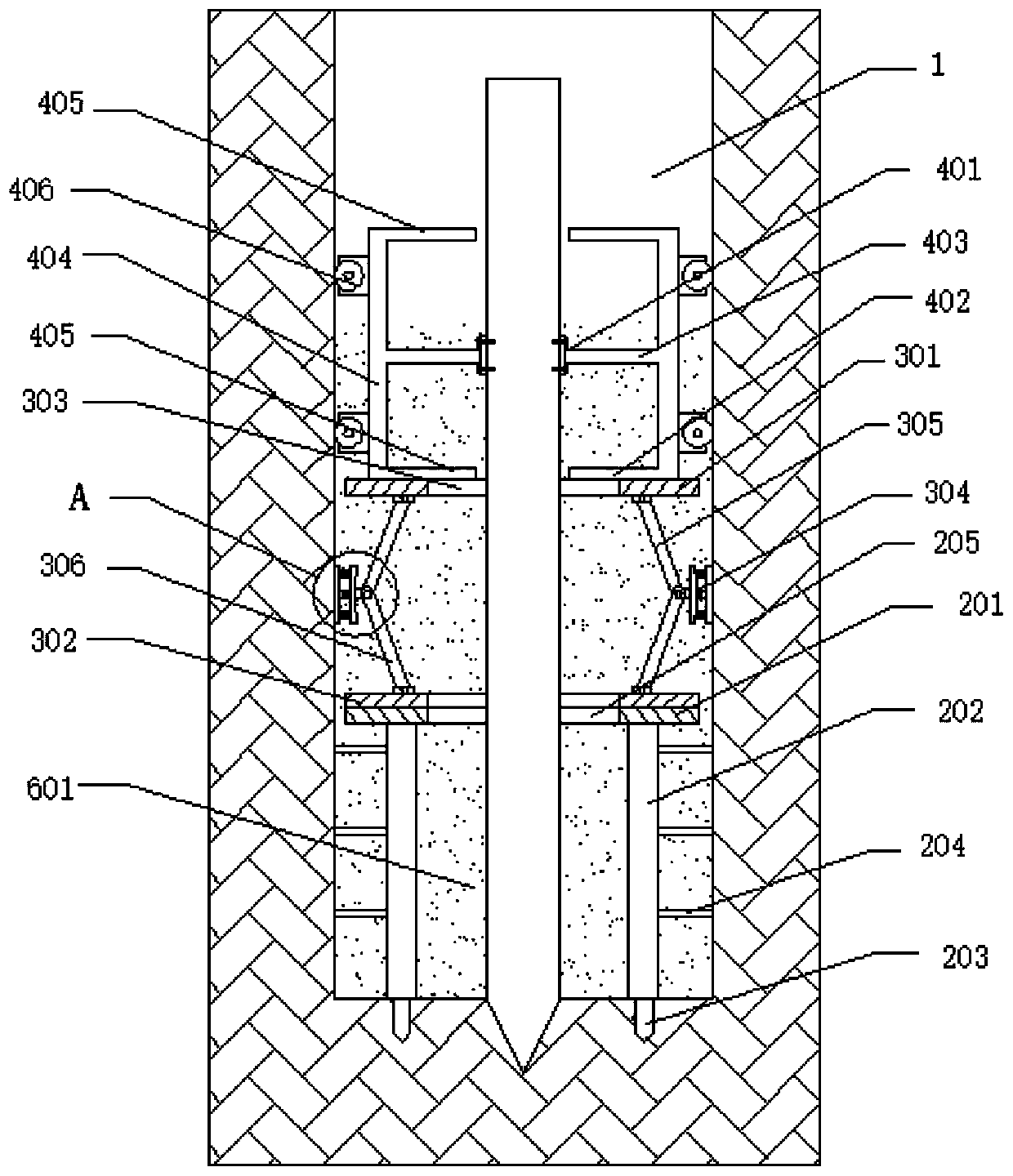

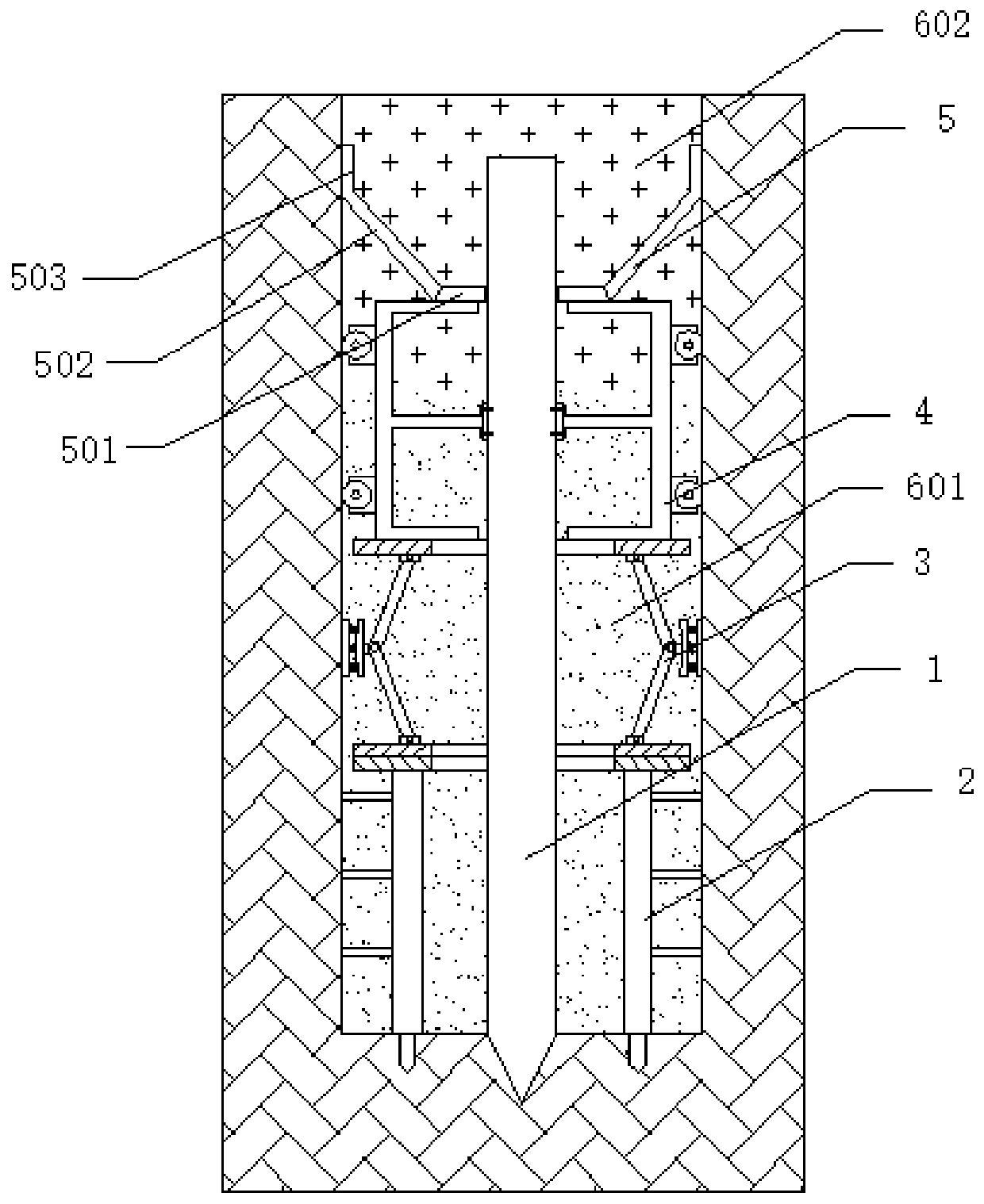

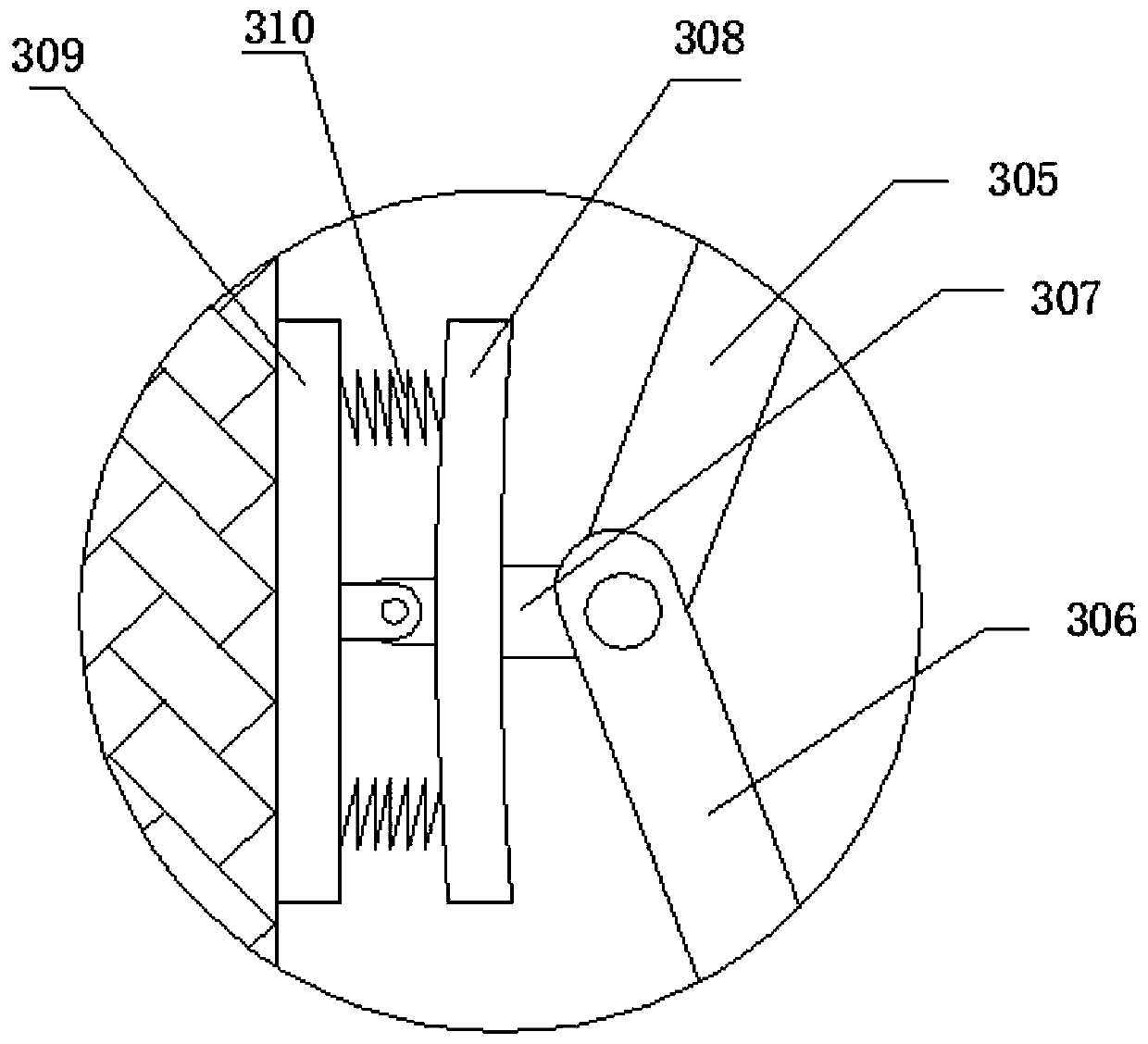

[0045] As shown in the figure, a civil engineering composite pile includes a plug-in column 1 inserted in the pile hole, and a first support assembly 2, a second support assembly 3, and a first The third support assembly 4 and the fourth support assembly 5 are poured with concrete in the pile hole 6 .

[0046] Further, the plug-in post is a cylindrical structure, the bottom of the plug-in post is inserted and fixed on the bottom of the pile hole, and the height of the plug-in post is 15-25cm smaller than the depth of the pile hole.

[0047] Further, the first support assembly includes a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com