Solid rocket engine, method for restraining residual propellant for propellant loading of solid rocket engine and combustion chamber structure

A technology of solid rockets and combustion chambers, which is applied to rocket engine devices, machines/engines, mechanical equipment, etc. It can solve problems such as longer working hours, reduced thrust, and impact on the overall performance of the engine, so as to improve strike accuracy and eliminate dragging The effect of the tail phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

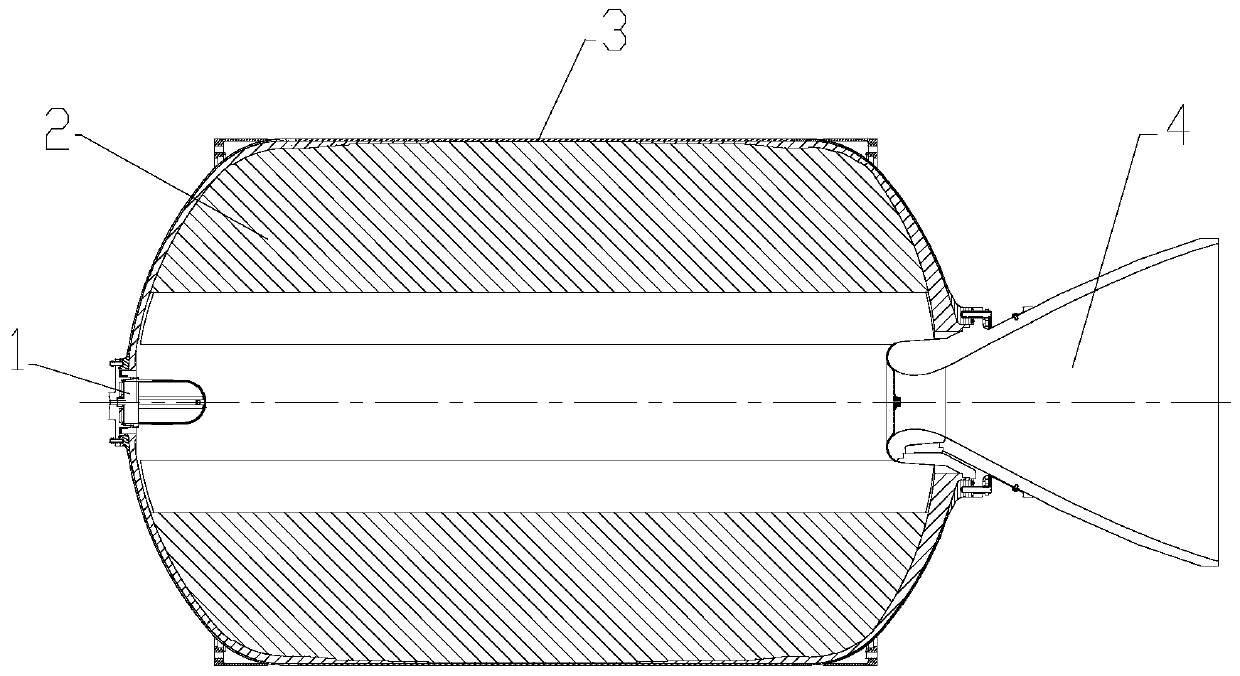

[0026] Such as figure 1 , figure 2 Shown is a solid rocket motor in the prior art, and its structure has been described in detail in the background technology section, and will not be repeated here.

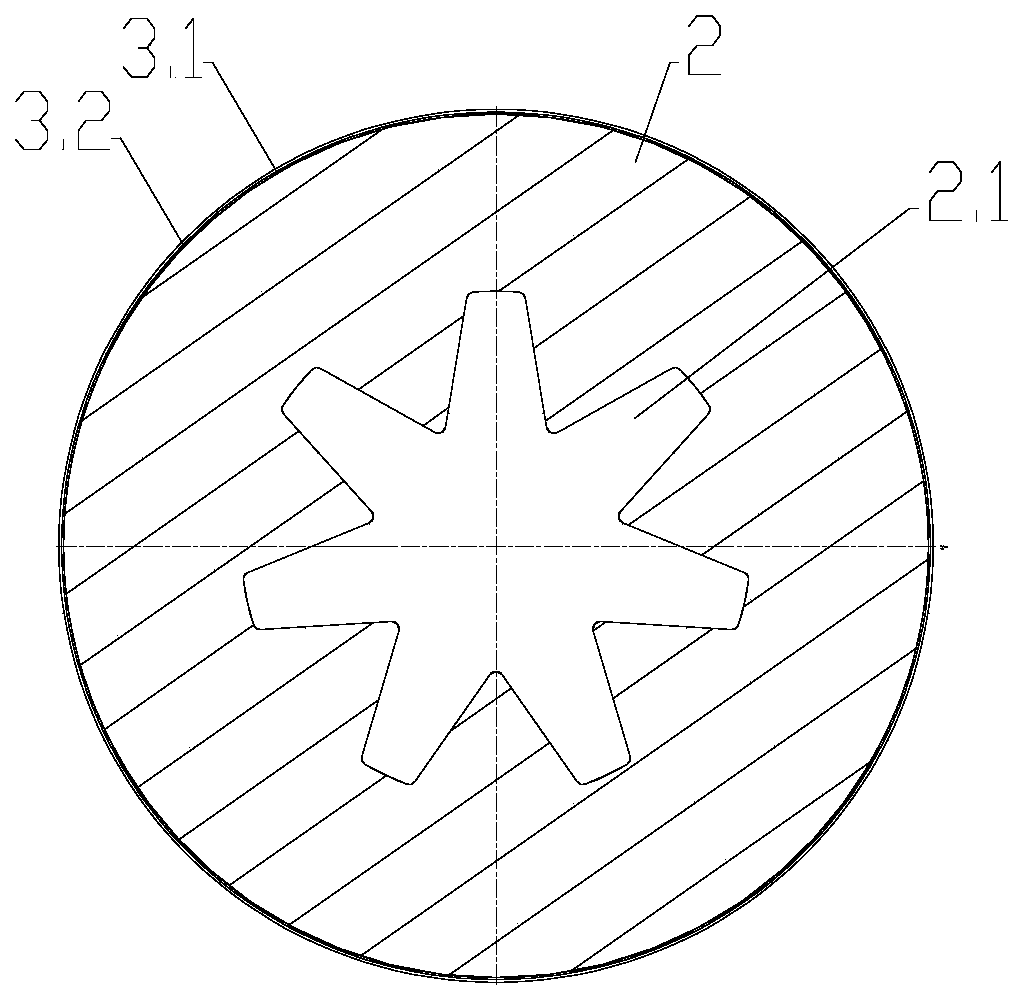

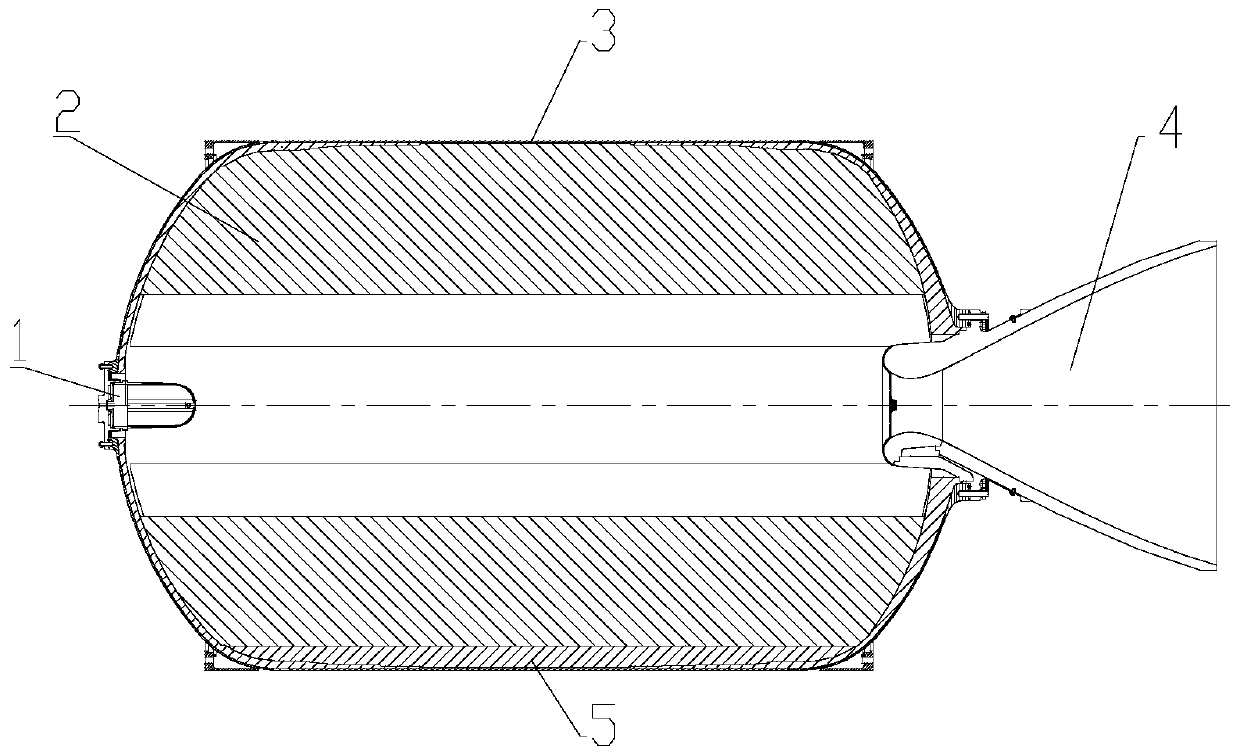

[0027] Such as Figure 3-5 As shown, the solid rocket motor ignition device 1 designed by the present invention, the grain 2, the combustion chamber 3 and the nozzle 4, the combustion chamber 3 includes the combustion chamber shell 3.1, the combustion chamber heat insulation layer 3.2, and the grain 2 has a star shape For the grain column in the inner hole, a residual medicine suppression member 5 is also arranged between the combustion chamber heat insulation layer 3.2 and the grain column 2 .

[0028] Remaining drug suppression part 5 is determined through the following steps:

[0029] 1) Determine the shape and position of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com