Copper core wire butt pliers for electrician

A copper core and wire technology, applied in the field of pliers, can solve the problems of copper core wires that are easy to bend, many processes, and time-consuming, and achieve the effect of ensuring the effect and splicing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

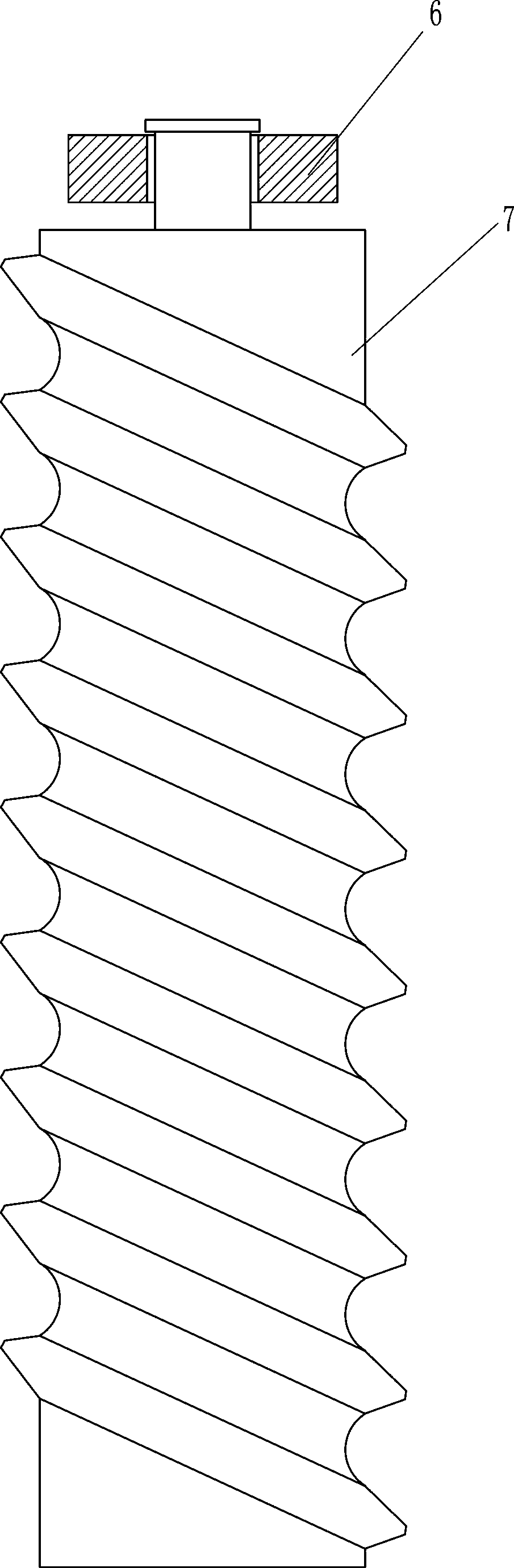

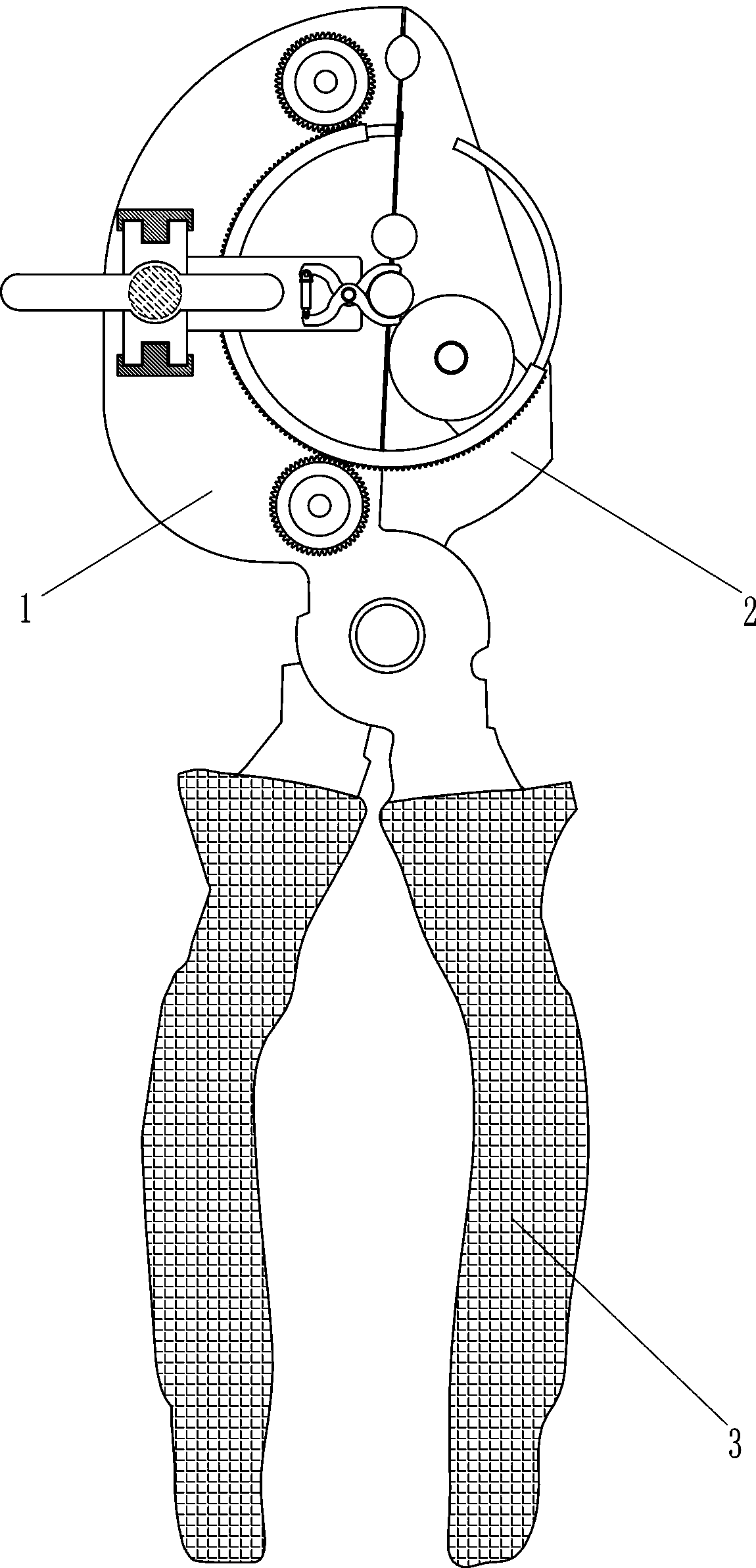

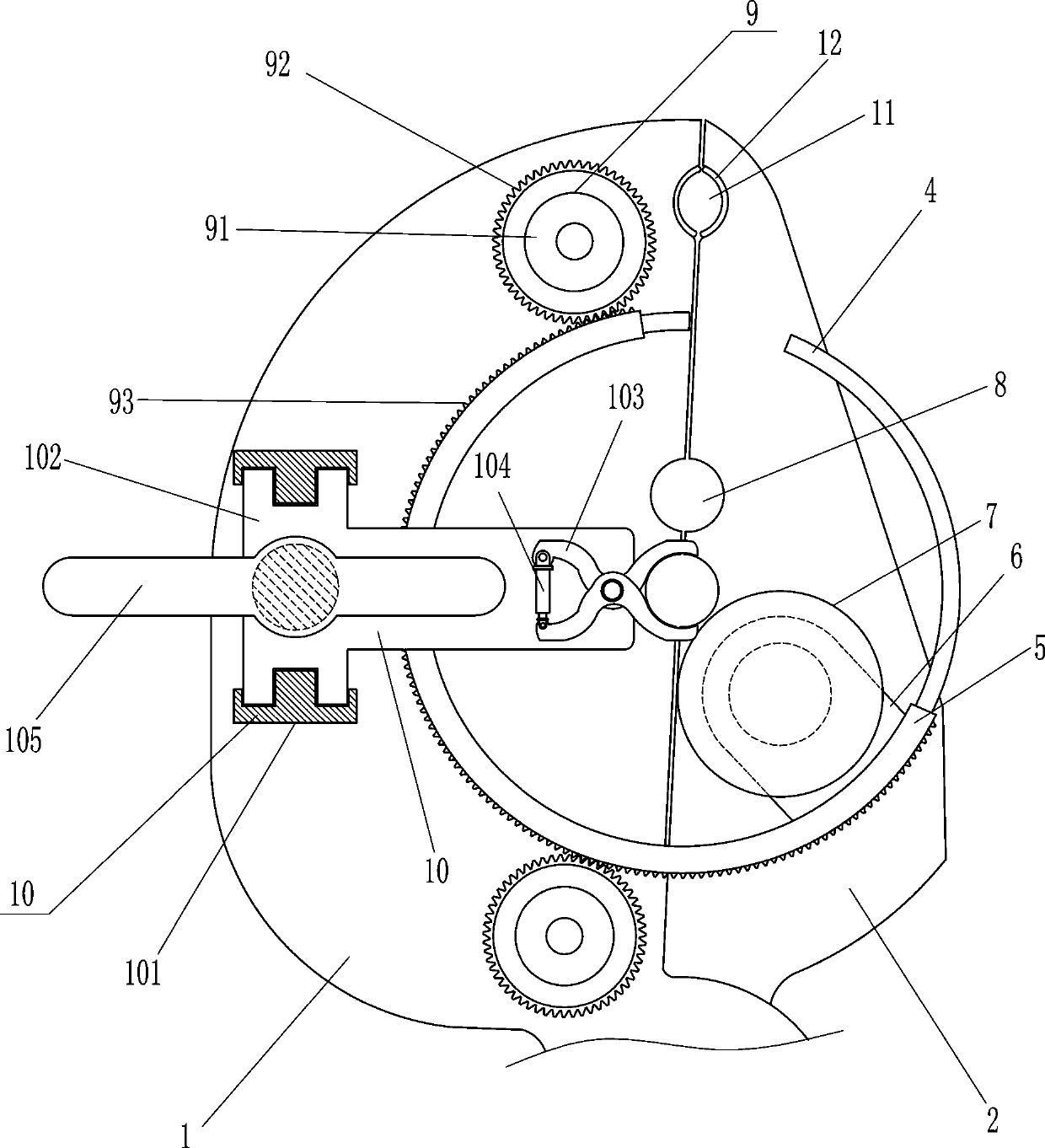

[0017] Such as Figure 1-3 As shown, a copper core wire butting pliers for electricians includes a first splint 1, a second splint 2 and a clamp handle 3. The first splint 1 is hingedly connected to a second splint 2, the first splint 1 and the second splint 2 are connected by a cross-pin hinged connection, the first splint 1 and the second splint 2 are both provided with a clamp handle 3, the first splint 1 and the second splint 2 are formed integrally with the clamp handle 3, and also include an arc The guide rail 4, the arc-shaped sliding sleeve 5, the support plate 6, the screw rod 7 and the driving device 9, the arc-shaped guide rail 4 is connected with the first splint 1 by bolt connection, and the arc-shaped guide rail 4 is provided with an arc sliding The inner side of the arc-shaped sliding sleeve 5 is provided with a supporting plate 6, and the supporting plate 6 is provided with a spiral rod 7 in a rotating manner. The spiral rod 7 is installed on the supporting plat...

Embodiment 2

[0022] On the basis of Example 1, such as image 3 As shown, the wire clamping device 10 is also included. The wire clamping device 10 includes a sliding frame 101, a sliding plate 102, a clamping rod 103, an electric push rod 104, and a T-shaped screw 105. The first clamping plate 1 is away from the second clamping plate 2. A sliding frame 101 is installed on the side, the sliding frame 101 is connected to the first splint 1 by bolt connection, the sliding frame 101 is provided with a sliding plate 102, the sliding plate 102 is slidingly fitted with the sliding frame 101, and the sliding plate 102 is hingedly connected with Two clamping rods 103, the two clamping rods 103 are arranged crosswise in a scissors shape, the middle of the two clamping rods 103 are connected to the sliding plate 102 by a shaft pin connection, the two clamping rods 103 are symmetric up and down, and the two clamping rods are up and down. An electric push rod 104 is connected between the tail ends of 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com