Production line apparatus for automatic production of decorative material

A decorative material and automatic production technology, applied in the direction of transportation and packaging, dissolving, mixing machines, etc., can solve the problems of low degree of automation and large amount of manual labor, and achieve the effect of improving production efficiency and reducing manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

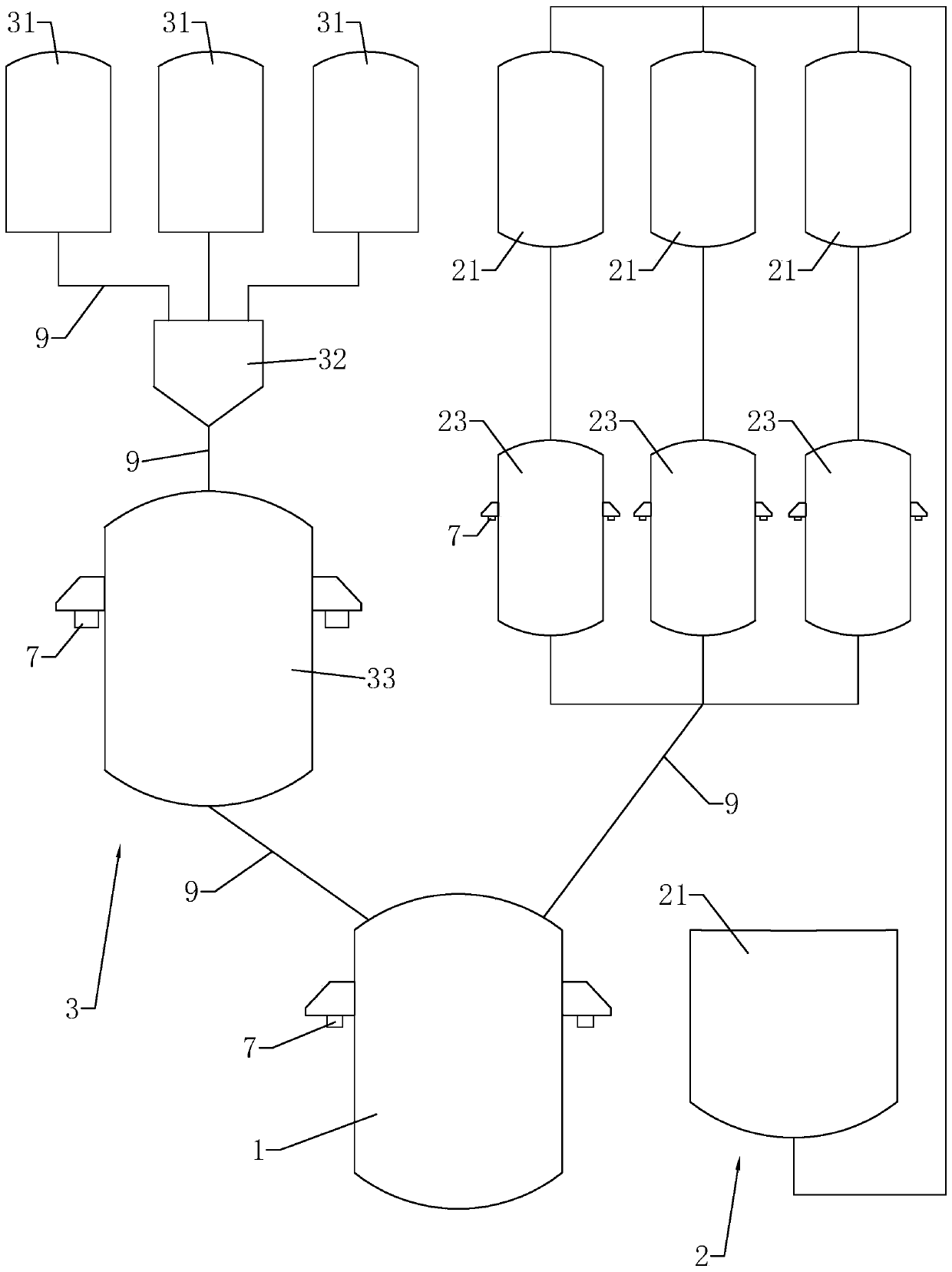

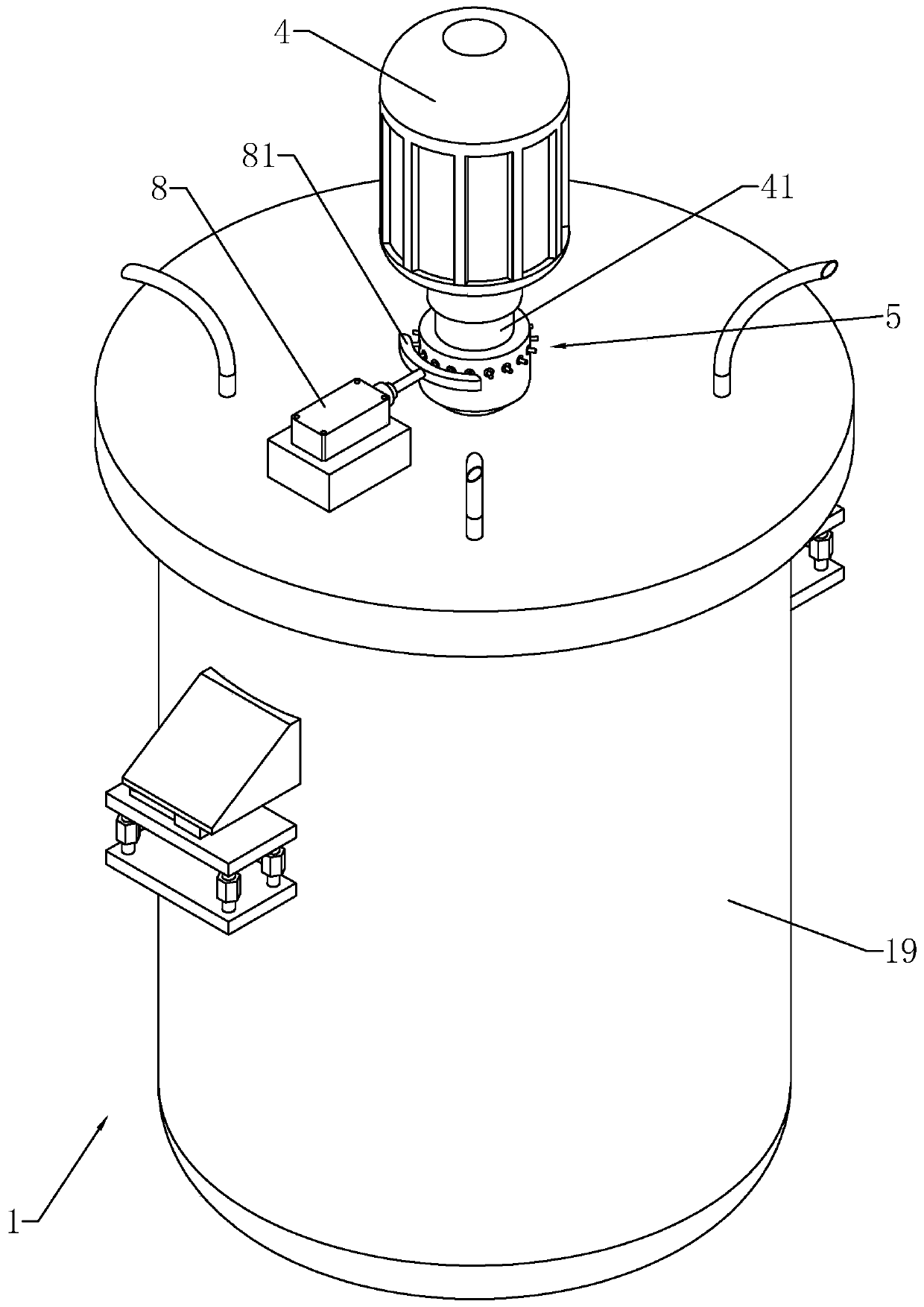

[0036] Example: Reference figure 1 , a production line device for automatic production of facing materials, comprising a mixing device, a particle feeding device 2 connected to the mixing device, and a solution proportioning device 3 . First, manually operate the transportation equipment to put the powdery particles into the particle feeding device 2, and transfer the particles to the mixing and stirring device through pneumatic conveying. device, particles and solutions are stirred and mixed in a mixing and stirring device according to a certain ratio to form a product.

[0037] refer to figure 1The particle feeding device includes a bin pump 21 for storing particles, a number of sand bins 22 connected to the bin pump 21, and a real-color stone kettle 23 connected to the sand bin 22. There are three sand bins 22 for alternate use at intervals, or A plurality of mixing and stirring devices are set to match the sand bin 22 . The warehouse pump 21 is located on the first floo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com