Manifold assembling device

A technology for assembling device and sub-catchment, which is applied in metal processing and other directions, can solve the problems of inability to meet production requirements, time-consuming, low processing and assembling efficiency, etc., and achieves the effect of improving assembly and installation efficiency, high degree of automation, and shortening assembly time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

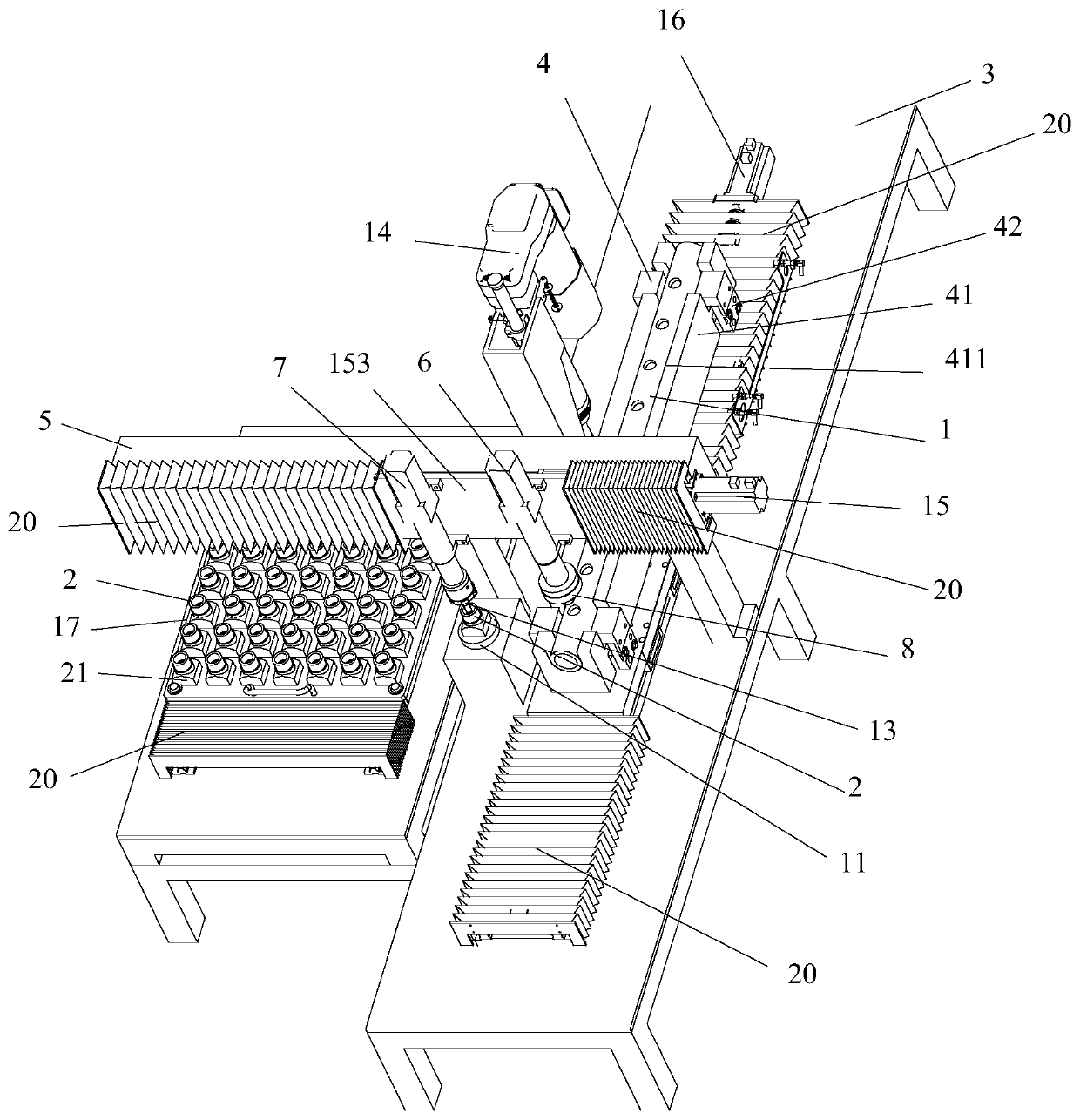

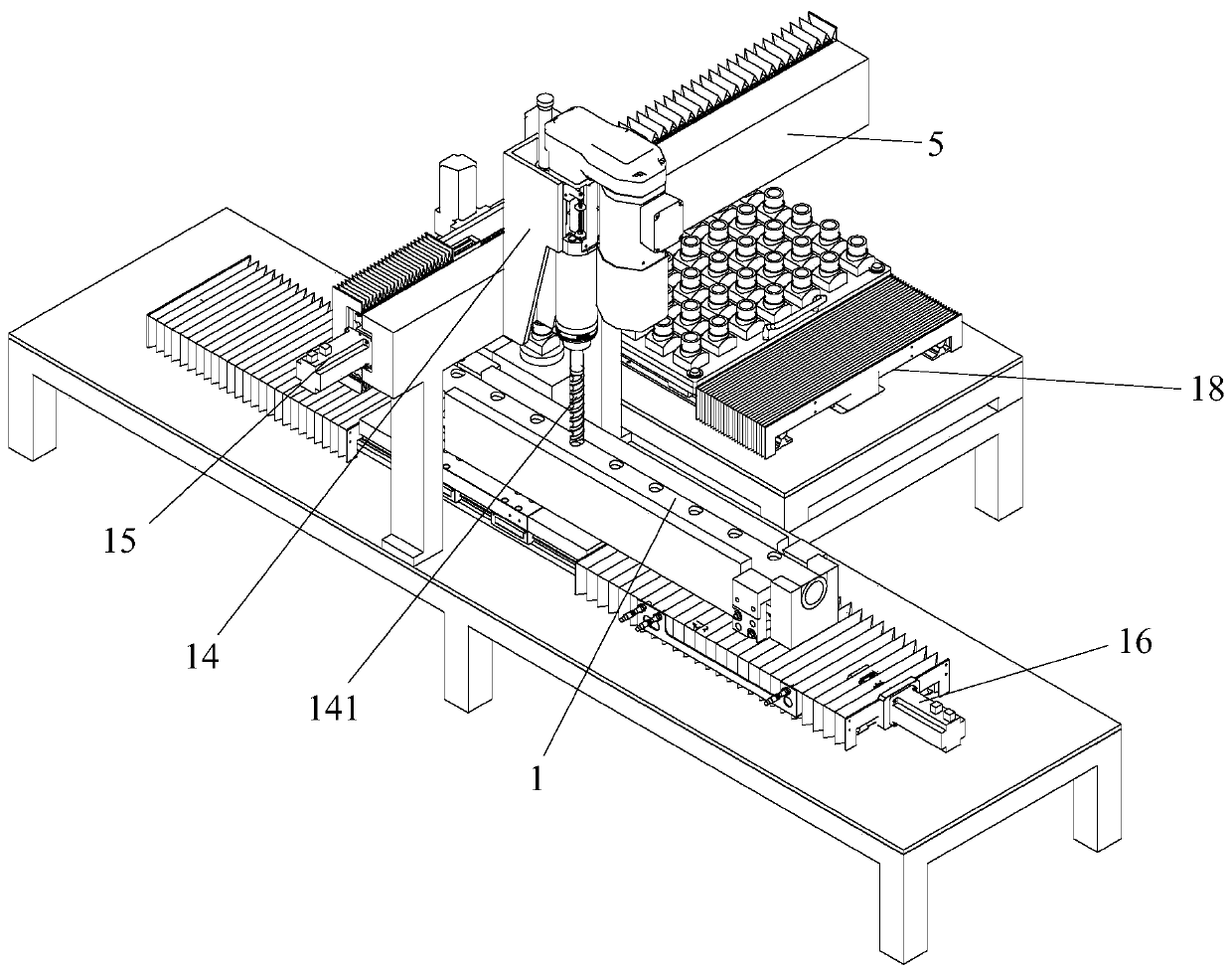

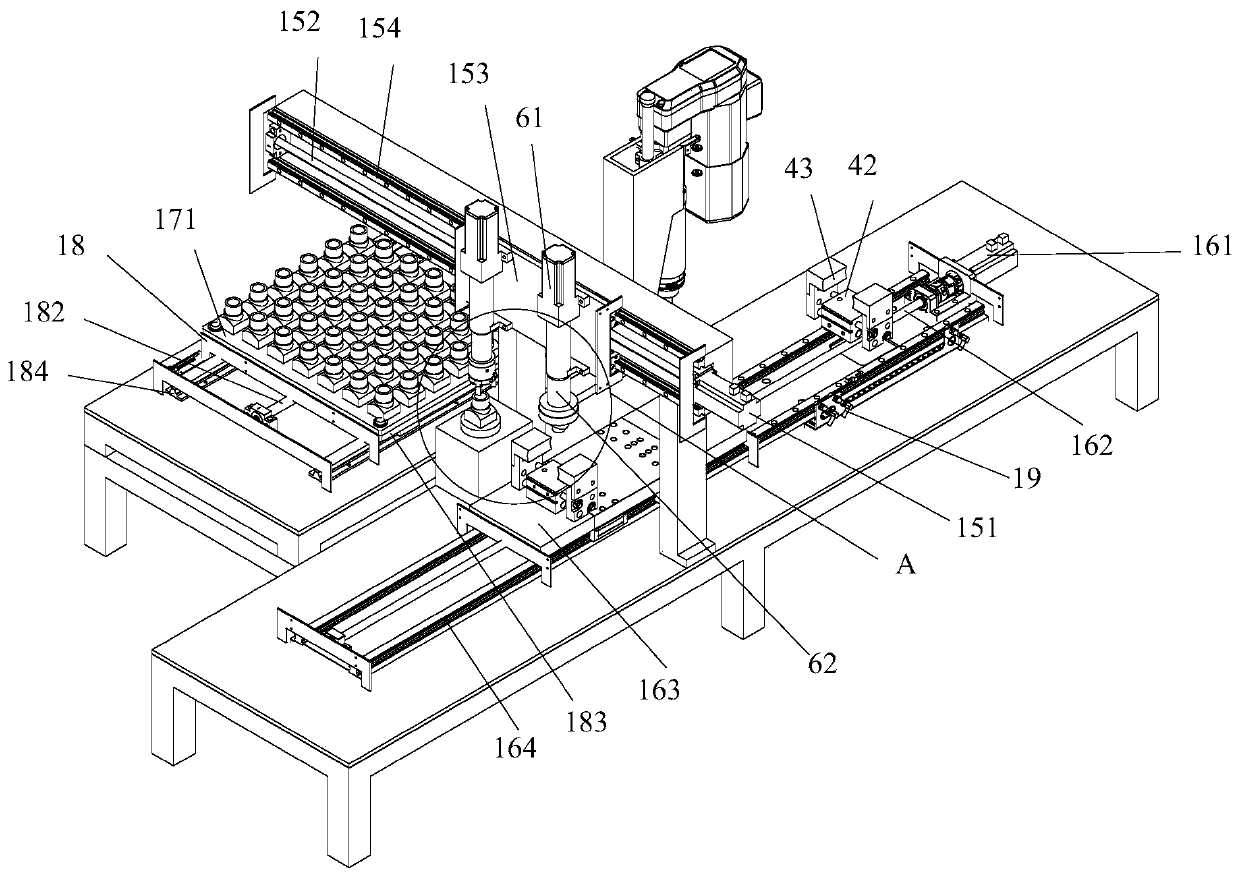

[0023] refer to Figure 1-Figure 5 , this embodiment discloses a sub-catchment assembly device, the sub-collector includes a pipe 1 and a joint 2 connected to the pipe 1, the assembly device includes a frame 3, and the pipe for transporting the pipe 1 is connected to the frame 3 The delivery device 4 and the support arm 5, one side of the support arm 5 is connected with a hot-melt assembly that can move along the length direction of the support arm 5, and the other side is connected with a drilling rig 14 for drilling the pipe 1 delivered by the pipe delivery device 4 , the hot-melt assembly includes a first lifting device 6 and a second lifting device 7, the first lifting device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com