Roller washing machine

A drum washing machine and door body technology, which is applied in the field of washing machines, can solve problems such as user inconvenience, opening the door body to spray water, leakage, etc., and achieve the effect of saving upper space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

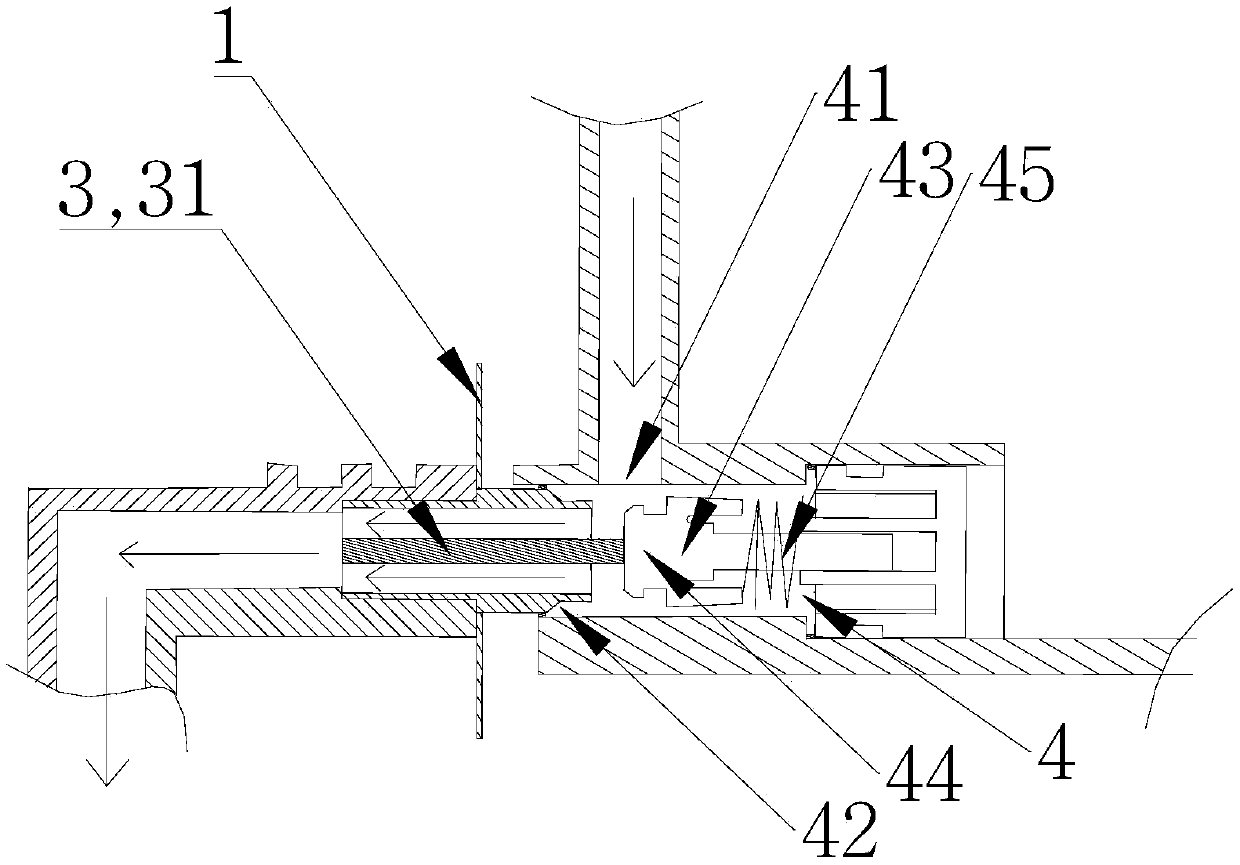

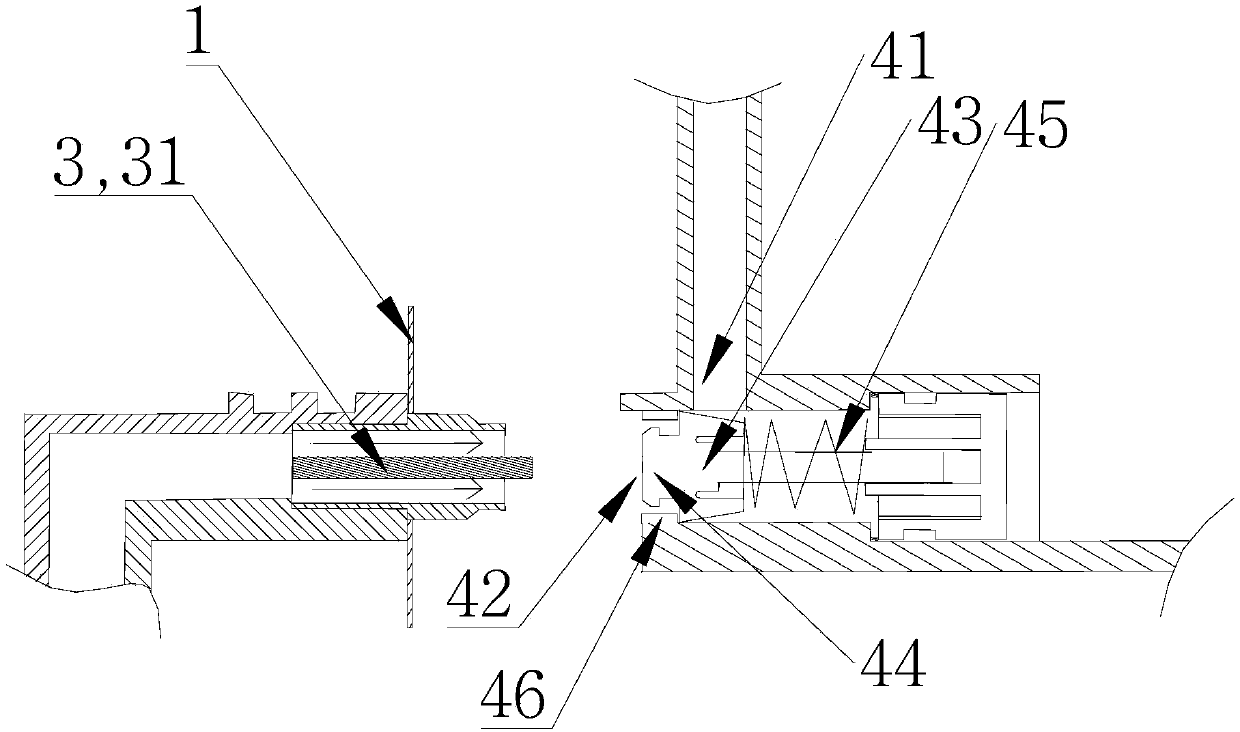

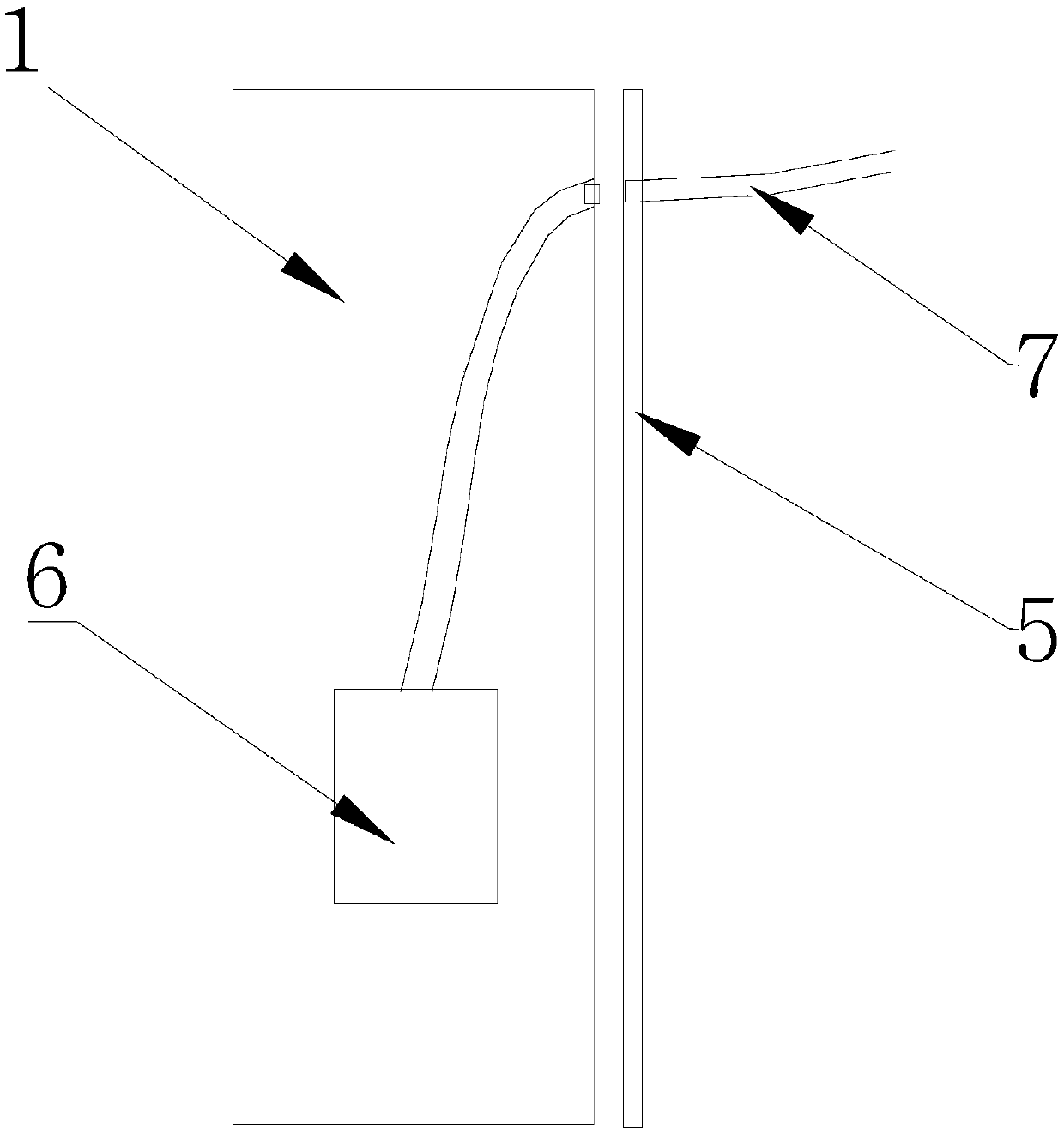

[0045] Such as Figure 1-5 As shown, a drum washing machine includes a casing 5, a door body 1, a water inlet pipeline 7 arranged in the casing 5, and also includes

[0046] A container 2 for holding detergent additives and a dispensing device 6 for dispensing detergent additives are arranged on the door body 1,

[0047] The dispensing device 6 communicates with the water inlet pipeline 7 when the door body 1 is closed, and is interrupted when the door body 1 is opened.

[0048] In the above scheme, the container 2 of the existing drum washing machine is mostly installed on the top or upper left of the washing machine, occupying a large amount of positions on the top or upper left of the washing machine, and because the space above the drum washing machine is narrow, the container 2 of these washing machines It is generally long and extends along the longitudinal direction of the washing machine, making it difficult for users to check the remaining amount of detergent in the ...

Embodiment 2

[0077] Such as Figure 1-5 As shown, in this embodiment, a drum washing machine includes a box body 5, a door body 1, and a water inlet pipeline 7 arranged in the box body 5, and also includes

[0078] Set on the door body 1, the container 2 for holding the detergent additive and the dosing device 6 for dispensing the detergent additive, the dosing device 6 and the water inlet pipeline 7 communicate with each other when the door body 1 is closed, and are interrupted when the door body 1 is opened.

[0079] Further, the water inlet pipeline 7 and the dispensing device 6 are provided with a conduction structure, and the conduction structure controls the connection between the water inlet pipeline 7 and the dispensing device 6 when the door body 1 is closed, and is interrupted when the door body 1 is opened.

[0080] Further, the conduction structure includes a split-type blocking part 4 and a top-opening part 3, the blocking part 4 is arranged on the box body 5, the top-opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com