Stator assembly, stator, motor and vehicle

A stator and component technology, applied in the fields of stator components, motors, vehicles, and stators, can solve the problems of increasing the additional loss of the motor, prolonging the axial length of the motor, increasing the difficulty of coil manufacturing, etc. The effect of difficult craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

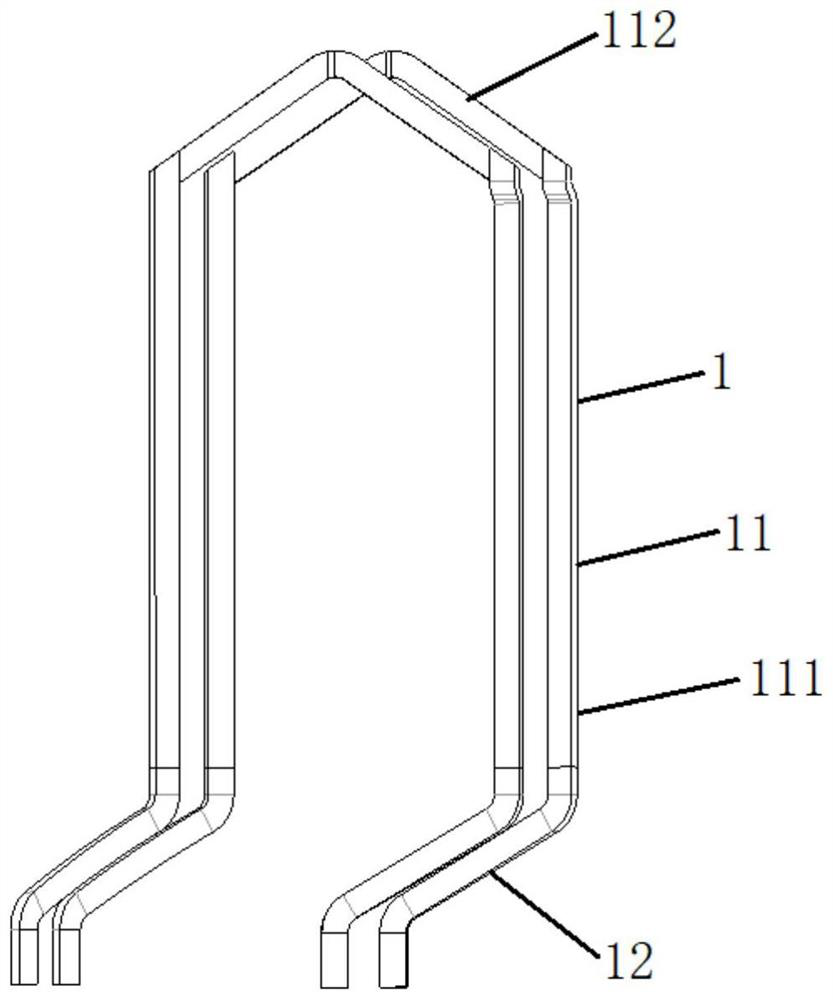

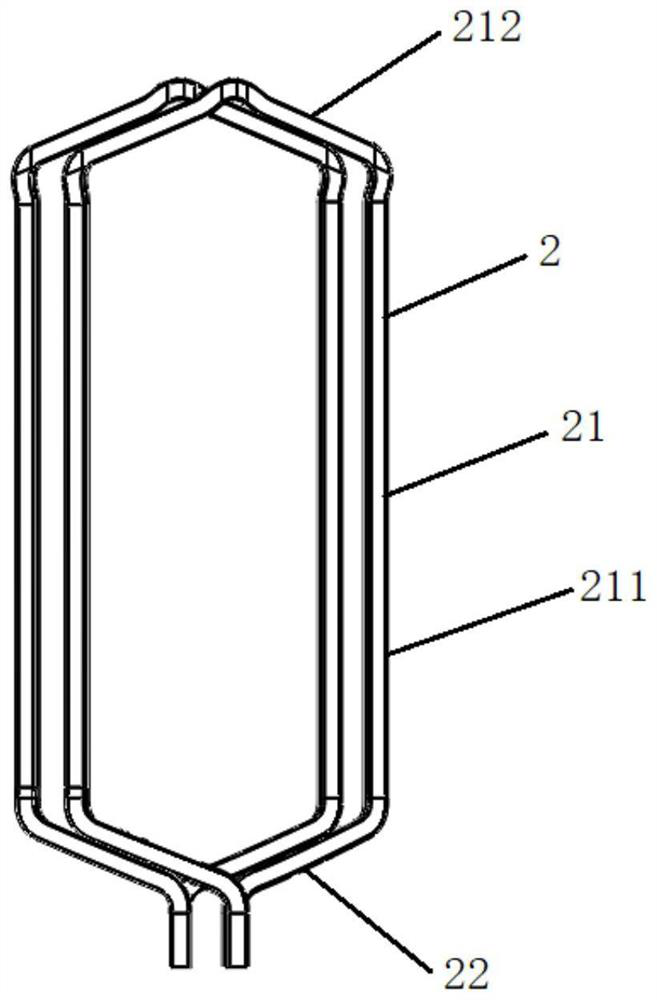

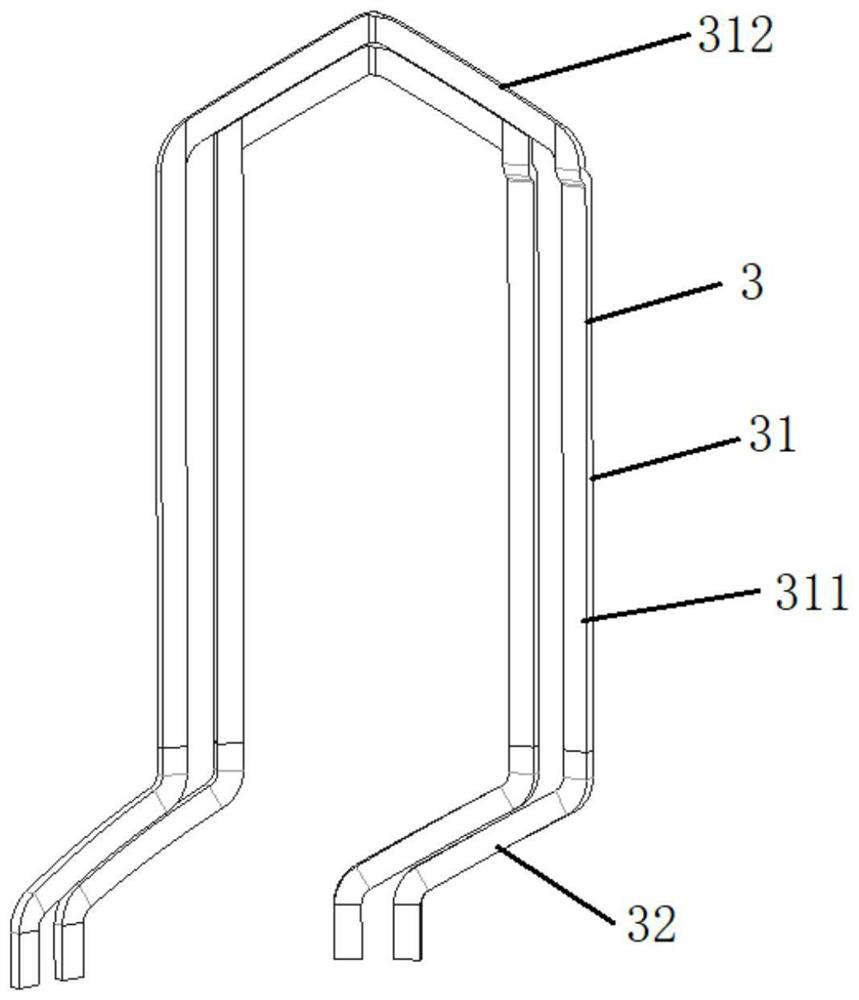

[0049] As shown in Figures 1 to 4 and Figures 6 to 8, the stator assembly of this embodiment includes three-phase phase windings, each phase winding package

[0055] As shown in FIG. 4, in this embodiment, a single coil includes a fourth coil 4, and the fourth coil 4 includes a fourth coil body

[0056] In this embodiment, the heads of the first coil 1, the second coil 2 and the third coil 3 are all V-shaped or arc-shaped. in

[0059] In this embodiment, the neutral points of each coil (a39, b39 in FIG. 8 ) are connected through the annular copper busbar 6,

[0073] The present embodiment also provides a motor comprising the above-mentioned stator, which can be applied to an electric vehicle / electric vehicle

[0074] This embodiment also provides a vehicle comprising the above-mentioned motor, and the vehicle may be an electric vehicle / electric vehicle

Embodiment 2

[0076] As shown in FIG. 1, FIG. 3 to FIG. 5, and FIG. 9 to FIG. 11, the stator assembly of this embodiment includes three-phase phase windings, each phase winding

[0081] As shown in FIG. 4, in this embodiment, a single coil includes a fourth coil 4, and the fourth coil 4 includes a fourth coil body

[0083] In this embodiment, the heads of the first coil 1, the third coil 3 and the fifth coil 5 are all V-shaped or arc-shaped. in

[0099] The present embodiment also provides a motor comprising the above-mentioned stator, which can be applied to an electric vehicle / electric vehicle

[0100] This embodiment also provides a vehicle comprising the above-mentioned motor, which can be an electric vehicle / electric vehicle

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com