Method for manufacturing LED (light emitting diode) illuminating device of light steel frame ceiling

A production method and technology of light steel frame, which are applied to the parts of lighting devices, lighting devices, fixed lighting devices, etc., can solve the problems of low installation efficiency and inability to meet large-area construction, and save material costs and head space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

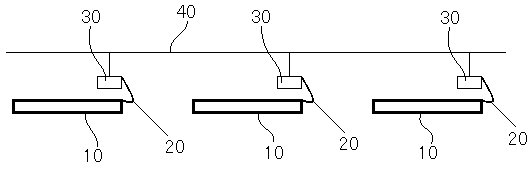

[0028] refer to figure 1 , figure 2 Shown, a kind of manufacturing method of LED light steel frame suspended ceiling lighting is characterized in that, comprises the following steps:

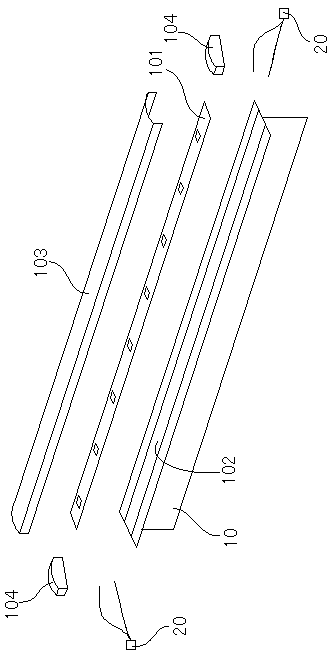

[0029] Step 1) Attach the LED light bar 101 to the light steel frame 10 at the position required for lighting with a heat-conducting double-sided adhesive 102;

[0030] Step 2) Connect the wire at one end of the double-head connector 20 to the LED light bar, and place the other end on the other side of the ceiling;

[0031] Step 3) Connect the LED drive power supply 30 to the other end of the double-head connector 20, and connect the AC power cord 40;

[0032] Step 4) Attach the PC diffuser lampshade 103 to both sides of the light steel frame, and install the dust cover 104 on both sides of the lampshade;

[0033] Step 5) Turn on the AC power to complete the lighting device. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com