Assembled folding type box room

A folding and prefabricated technology, applied in building types, special buildings, small buildings, etc., can solve the problems of small storage space, inconvenient transportation and installation, and achieve small storage space and solve the inconvenient transportation and installation of box rooms. , good economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

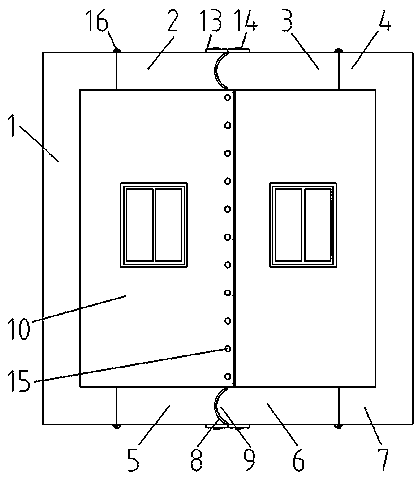

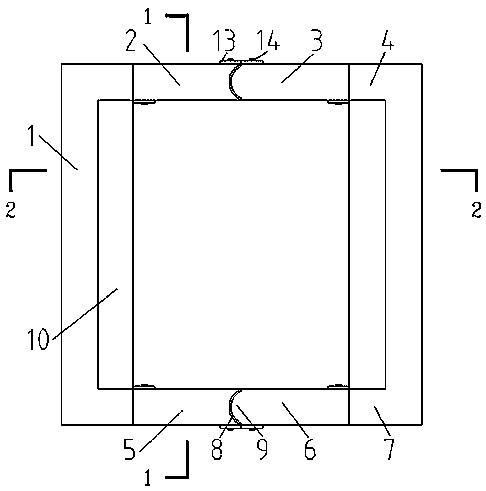

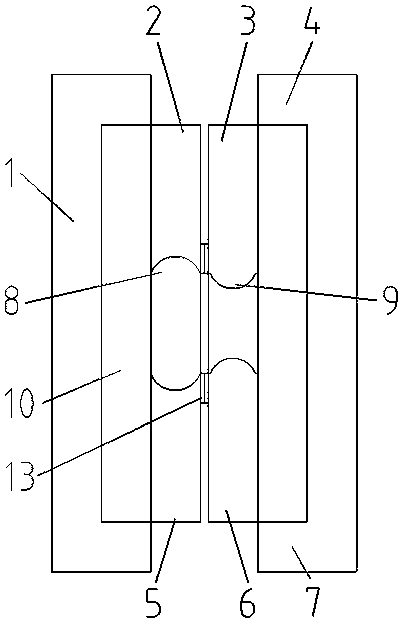

[0035] Example: such as Figure 1-Figure 5As shown, a prefabricated folding container house of the present invention includes a side plate 1, a first top plate 2, a second top plate 3, a top plate end 4, a first bottom plate 5, a second bottom plate 6, a bottom plate end 7, an arc shaped groove 8, arc-shaped protrusion 9, first folded plate 10, second folded plate 11, folded plate chuck 12, metal hinge 13, bolt 14, pull bolt 15; the cross section of the side plate 1 is rectangular , the height is the same as the height of the box room, and is located at both ends of the box room; the section of the top plate end 4 and the bottom plate end 7 is rectangular, and the length is the same as the thickness of the first folded plate 10 and the second folded plate 11, and the side plate 1 It is integrally connected with the top plate end 4 and the bottom plate end 7. The top plate end 4 and the bottom plate end 7 are respectively located at the upper end and the lower end of one side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com