A Design Method of Adjustable Electrical Thickness Fitting Reflection Test Waveguide Probe

A reflection test and design method technology, applied in the test field, can solve the problems that the reflection coefficient phase cannot reflect IPD monotonously, restrict the direct application of the reflection method, etc., and achieve a good measurement linearity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

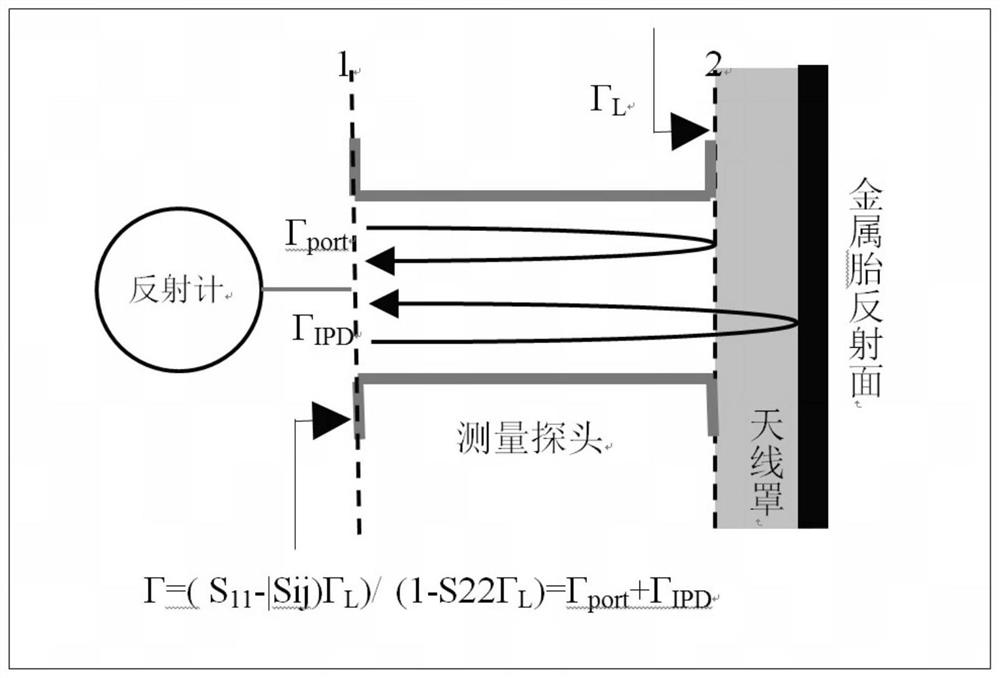

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0025] A method for designing waveguide probes with adjustable electrical thickness for reflection testing, comprising the following steps:

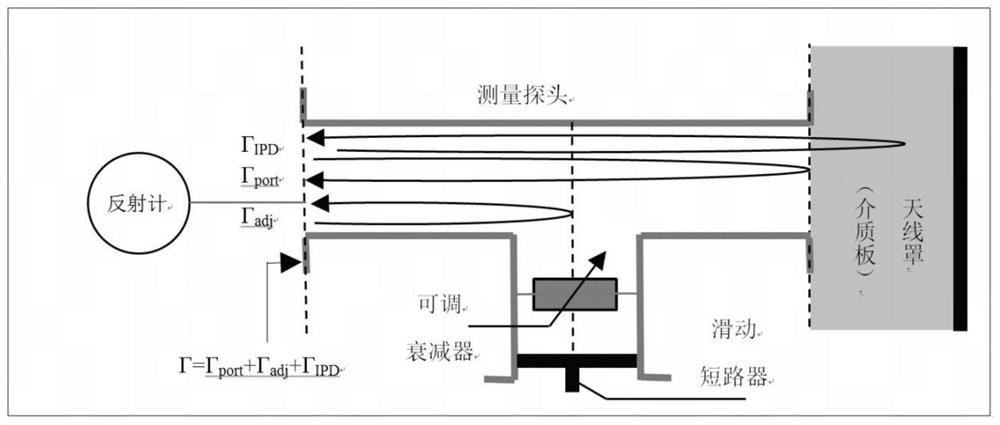

[0026] Step 1: Add a parallel stub to the test waveguide to form a three-port microwave network structure, such as figure 2 As shown, the parallel stubs include adjustable attenuators and sliding shorts, and the parallel stubs will introduce an additional reflection coefficient component Γ adj , the role of the parallel branch is to adjust Γ adj , making it the same as Γ port Equivalent inversion, so that Γ adj with Γ port cancel each other out, making Γ close to Γ IPD ;

[0027] Step 2: Connect the port of the test waveguide (such as the right port) to the dielectric plate of the same material as the radome with the electrical thickness to be tested;

[0028] Step 3: Set the attenuation of the adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com