Spraying machine for wet-mixed mortar mechanical spraying construction

A technology of mechanical spraying and wet-mixing mortar, which is applied in the direction of construction and building construction, and can solve the problems of spraying machine jamming, damage to the spraying machine, and affecting the normal operation of construction, so as to improve work efficiency and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

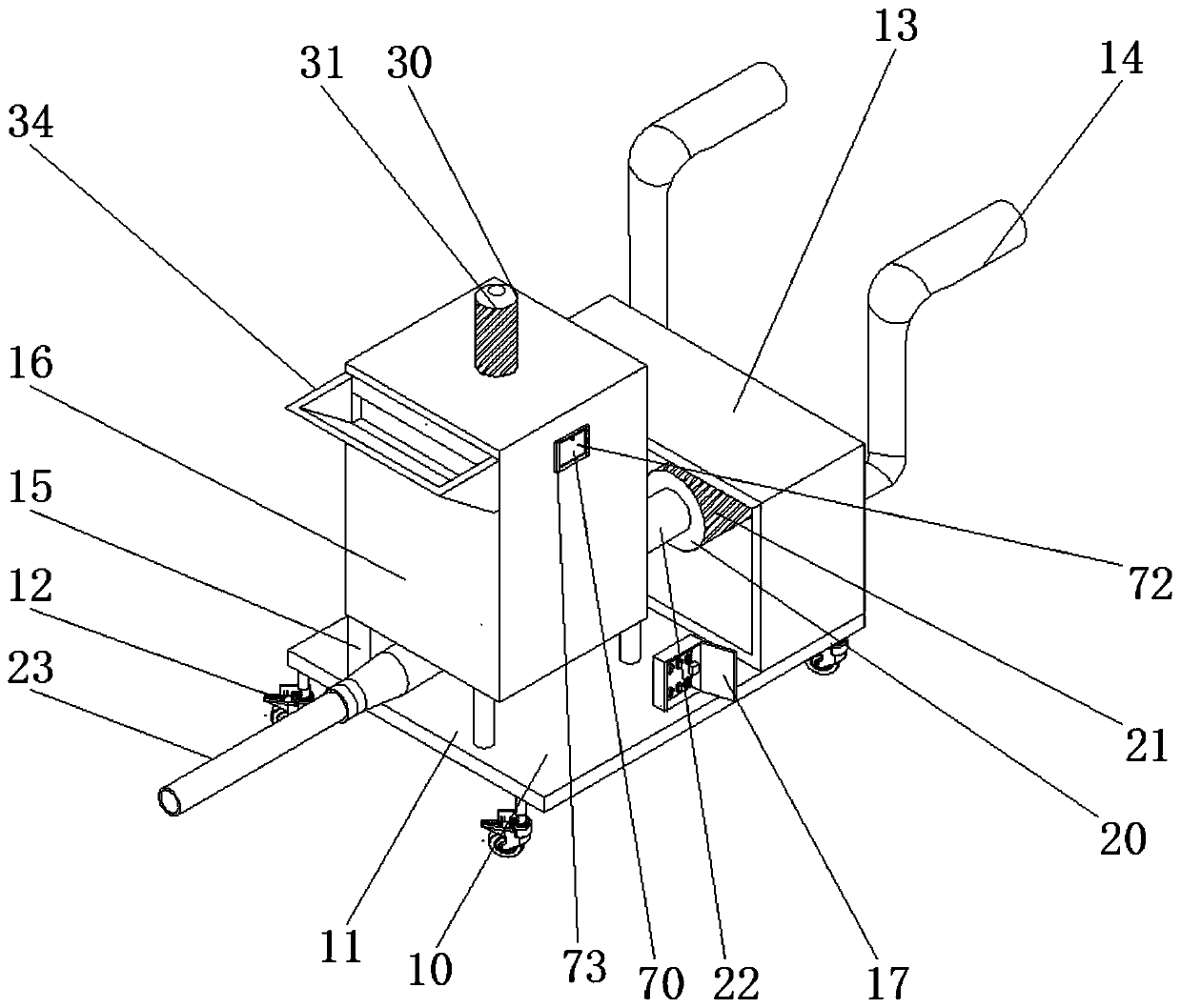

[0034] The present invention provides such Figure 1-5 The shown spraying machine for mechanical spraying construction of wet-mixed mortar includes: a main body assembly 10, and the main body assembly 10 includes a support plate 11, a walking wheel 12, a first housing 13, a push handle 14, a support rod 15, a second Two casings 16 and a power supply box 17;

[0035] A spraying assembly 20, the spraying assembly 20 is installed on the main body assembly 10;

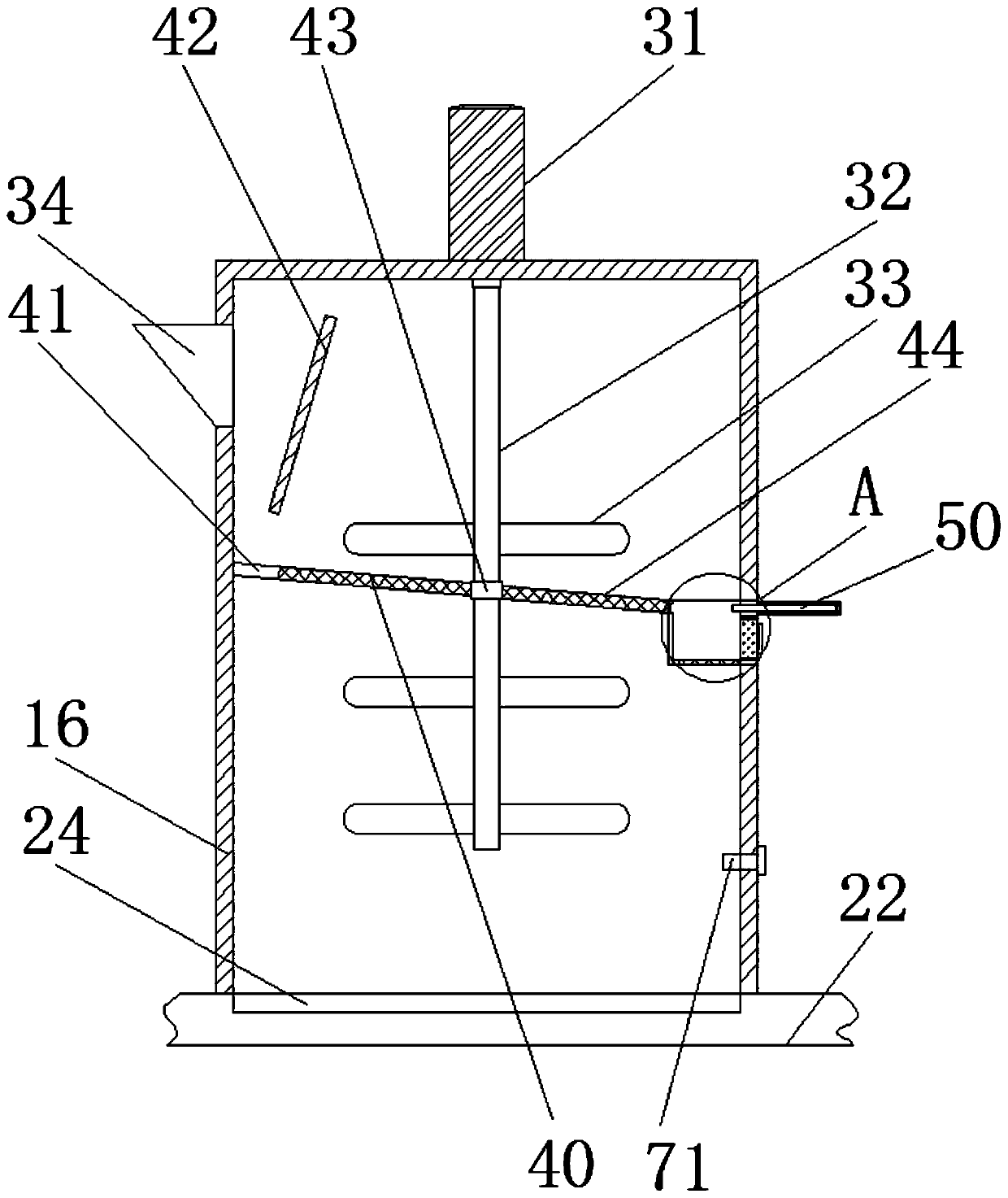

[0036] Stirring assembly 30, described stirring assembly 30 is installed on the described second housing 16, and described stirring assembly 30 comprises motor 31, rotating shaft 32, stirring blade 33 and feeding hopper 34;

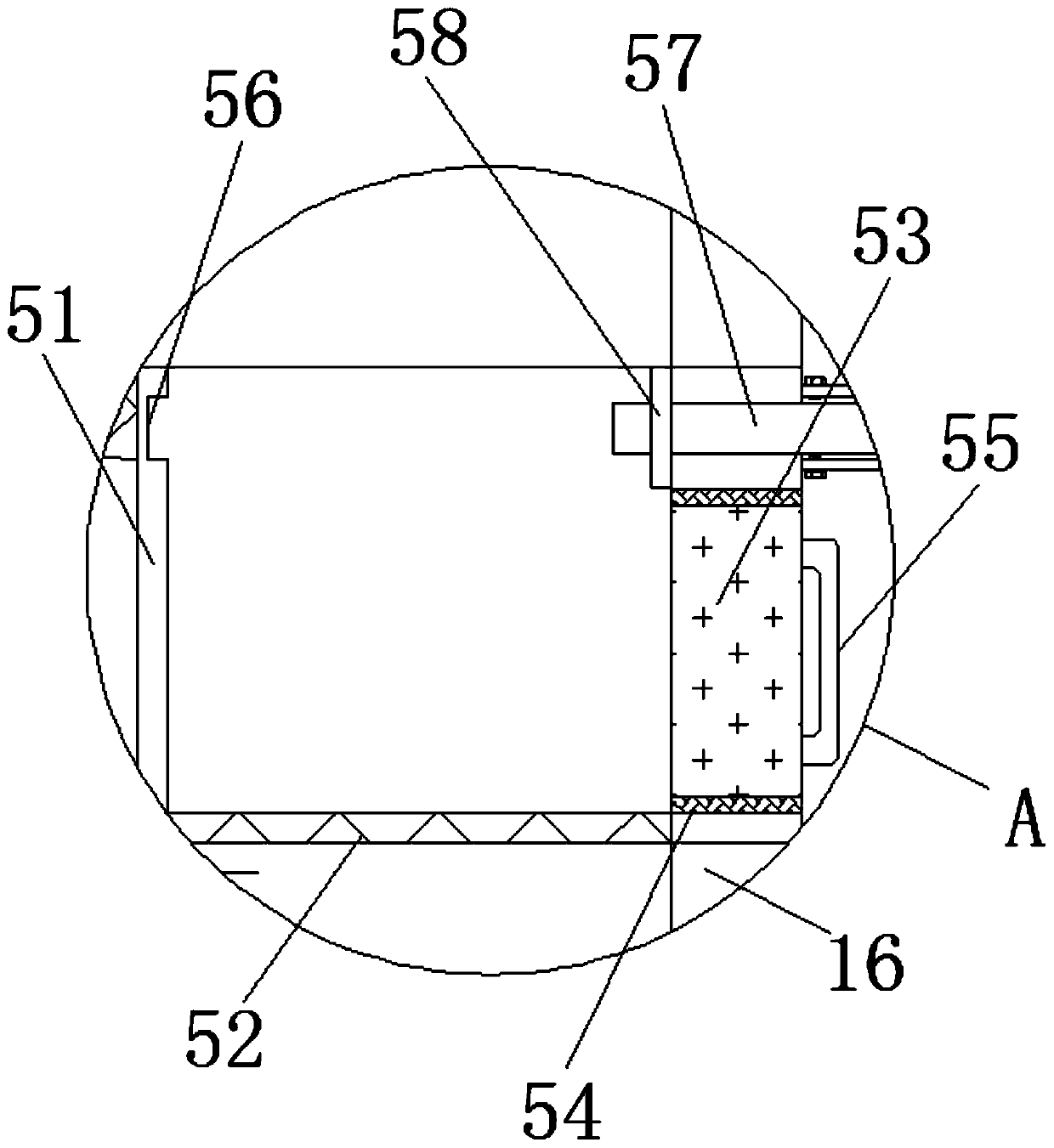

[0037] A filter assembly 40, the filter assembly 40 includes a protective plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com