Pressure sensor and packaging method thereof

A pressure sensor and packaging method technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, decorative arts, electric solid devices, etc., can solve the problem of sensitive film damage, large peripheral stress of the sensitive film, difficult to effectively prevent the sensitive film Damage and other problems to achieve the effect of extending the service life and enhancing the overall protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to the embodiments shown in the accompanying drawings. However, this embodiment does not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to this embodiment are included in the protection scope of the present invention.

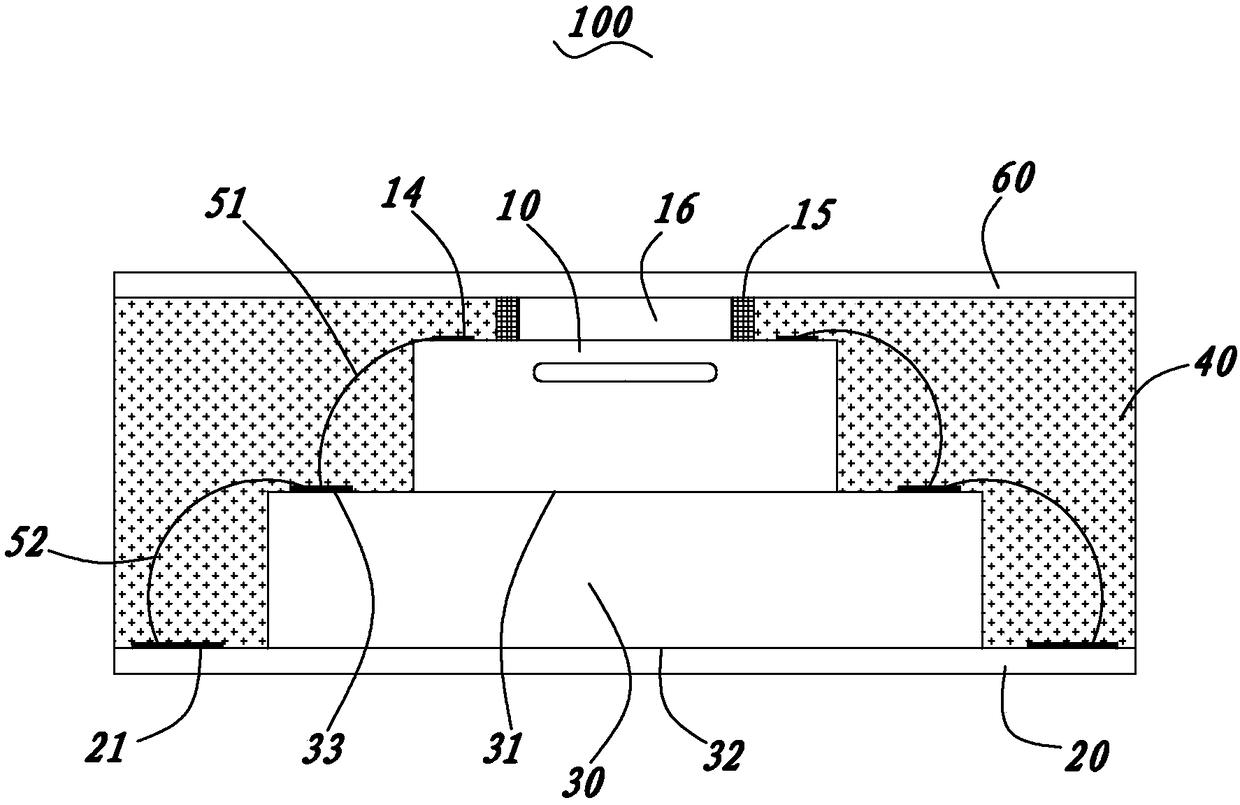

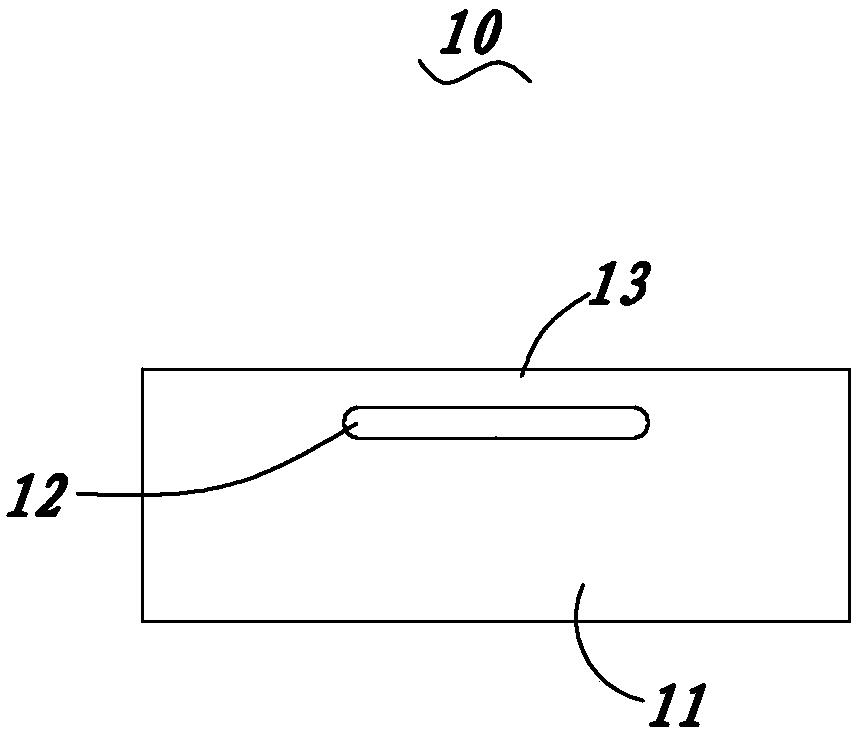

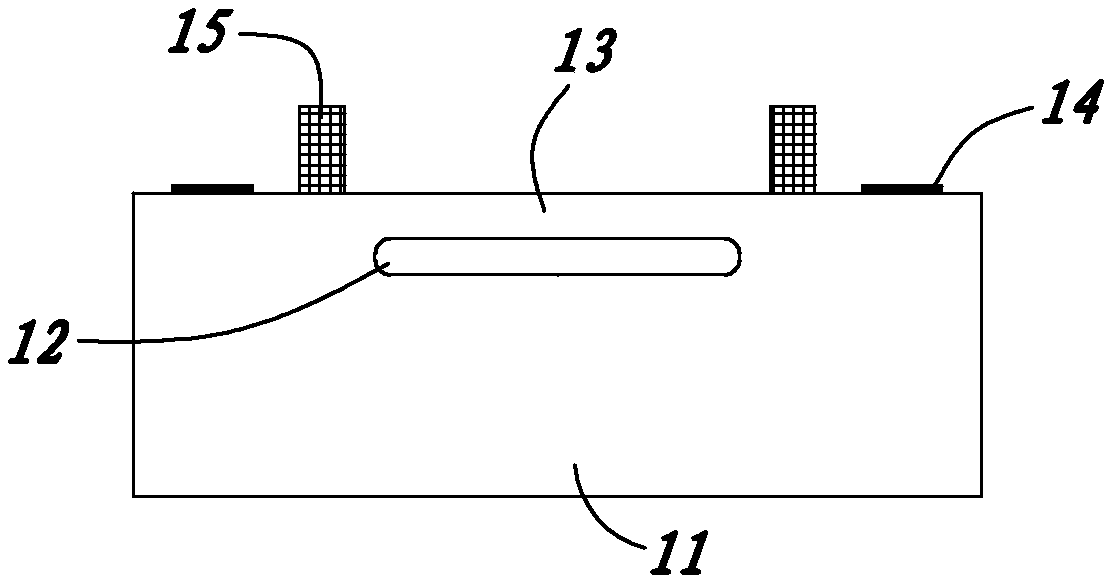

[0038] refer to Figure 1 to Figure 5 Shown is a preferred embodiment of the pressure sensor 100 of the present invention. The pressure sensor 100 provided by the present invention includes a stacked pressure sensor chip 10 and a substrate 20, the pressure sensor chip 10 includes a substrate 11, a cavity 12 formed on the side of the substrate 11 away from the substrate 20, and the The cavity 12 cooperates with the provided sensitive membrane 13 . The cavity 12 is flat; the first pad 14 is provided on the substrate 11 .

[0039] Preferably, the first pad 14 is made by using processes such as deposition, photo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com