Surround type vibrator vehicle cab protective device for preventing continuous rolling

A technology of protection device and seismic source vehicle, which is applied in the direction of transportation and packaging, vehicle parts, and the upper structure of trucks, etc., to increase the protection area, prevent continuous rolling, and improve the effect of deformation and energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The concept, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, characteristics and effects of the present invention.

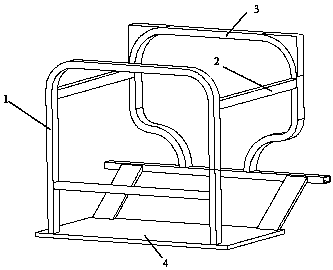

[0015] like figure 1 , The surrounding type anti-continuous rollover anti-vibration source vehicle cab protection device of the present invention is mainly composed of a front guard 1, a beam 2, a rear guard 3 and a base 4.

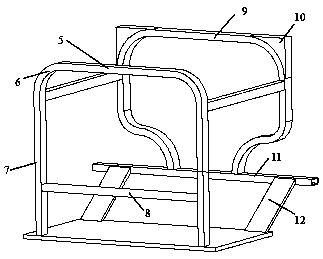

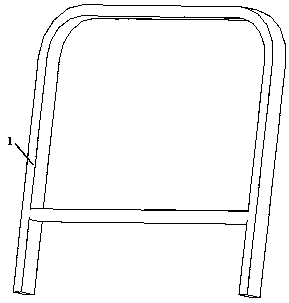

[0016] figure 2 It is a schematic diagram of the surrounding type anti-continuous rollover anti-vibration vehicle cab protection device according to a preferred embodiment of the present invention. In this embodiment, the cab protection device for the rollover of the vibrator-controlled vehicle adopts a surrounding structure as a whole, and the front guard 1 is as follows: image 3 As shown, the whole is welded by square and rectangular tubes, and this structure has a good energy absorption and bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com