Industrial data classification method based on model migration

A technology of industrial data and classification methods, applied in neural learning methods, biological neural network models, character and pattern recognition, etc., can solve the problem of less application of transfer learning methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the examples.

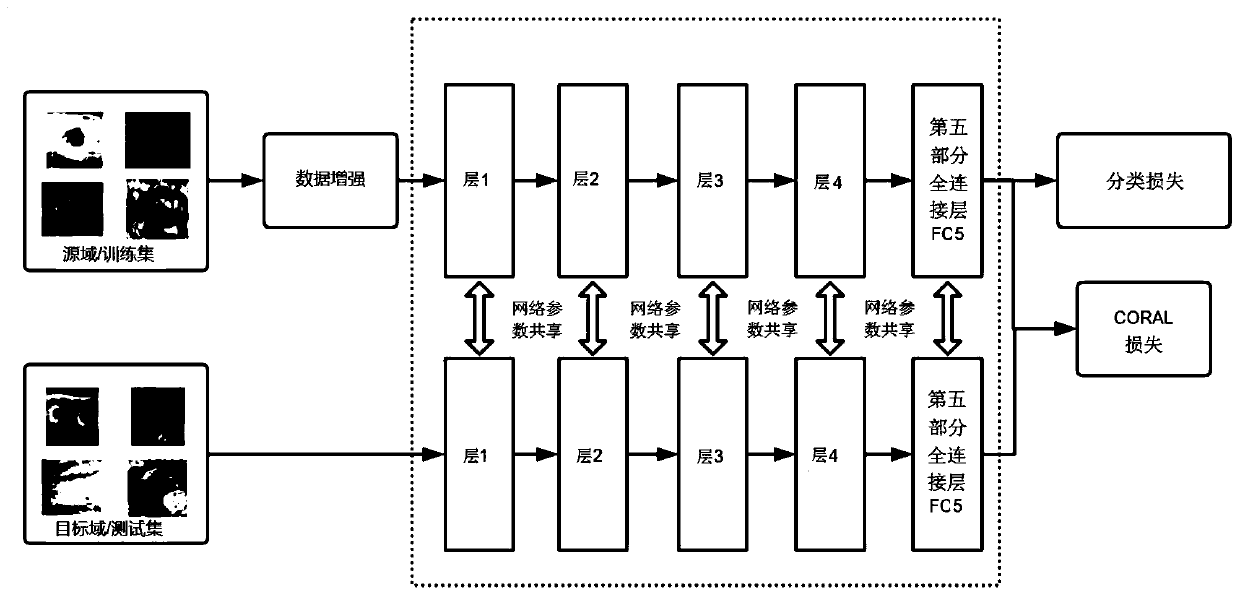

[0051] The invention discloses a method for classifying industrial data based on model migration, which includes the following steps (taking welding defects as an example):

[0052] Step A: Collect a large number of welding defect data sets A of different types of products in the industry as source domain data sets, and divide them into different folders according to the type of welding defects and number them (such as: 1-surface cracks 2-surface pores 3-undercut 4-welding bump);

[0053] Step B: Collect defect data to be classified of a small number of products to be tested (hundreds of pieces) as target domain data;

[0054] Step C: Perform data enhancement on the source domain data, expand the training set, increase the data feature density, and avoid overfitting;

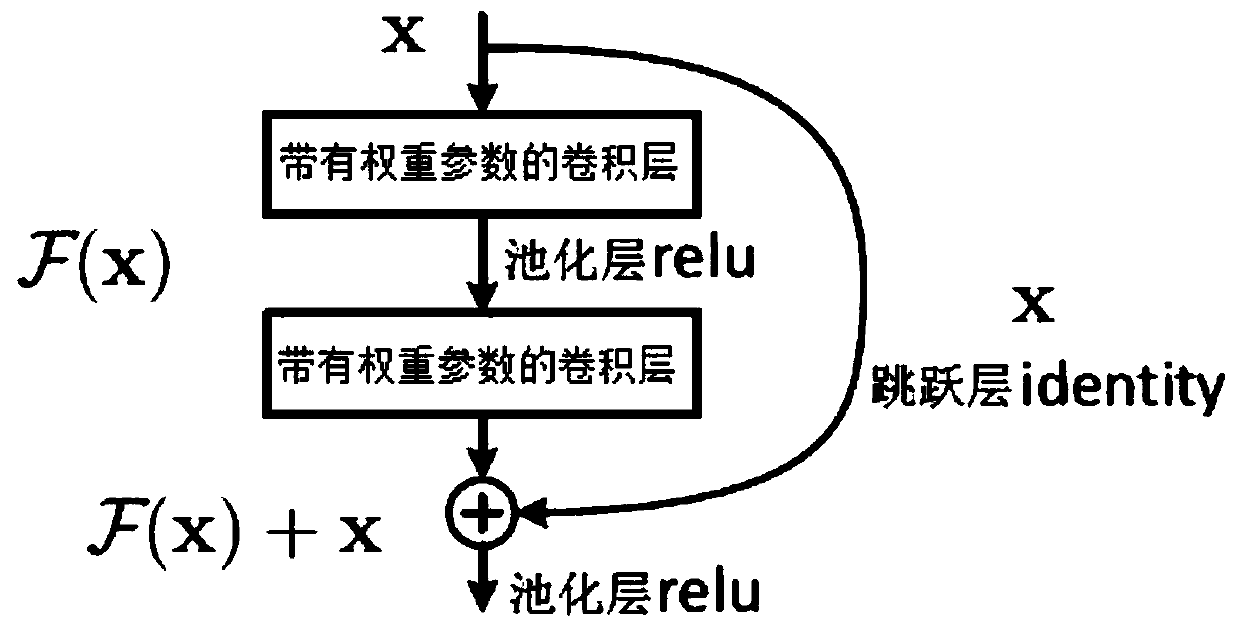

[0055] Step D: Construct a convolutional neural network with a residual structure;

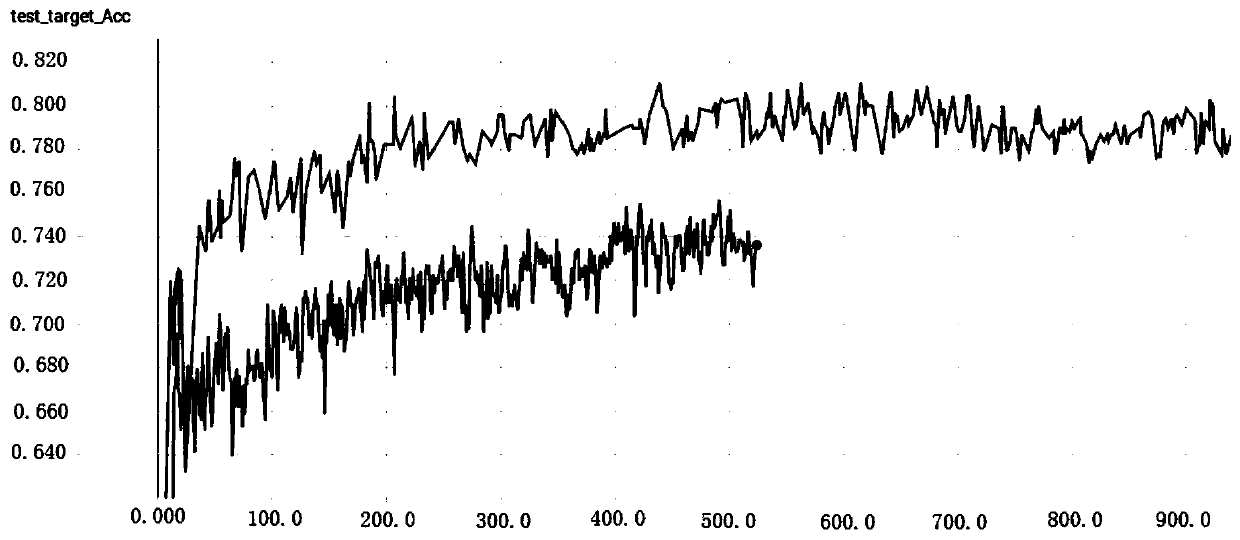

[0056] Step E: E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com