Lamp tube capable of being compatible with high frequency and power frequency and implementation method thereof

A light tube and power frequency technology, which is applied in the field of LED light tubes, can solve problems such as misuse damage, light failure, and difficulty in figuring out lamp holders, etc., to achieve the effect of ensuring safety and avoiding abnormal risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

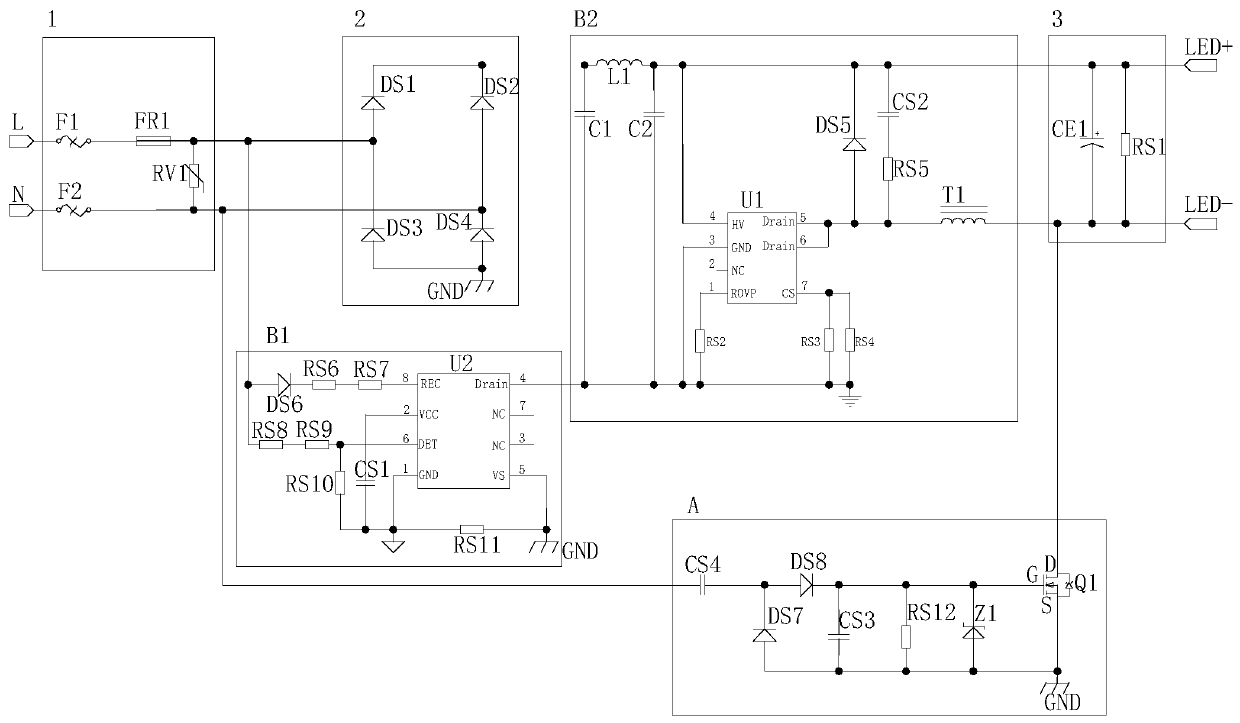

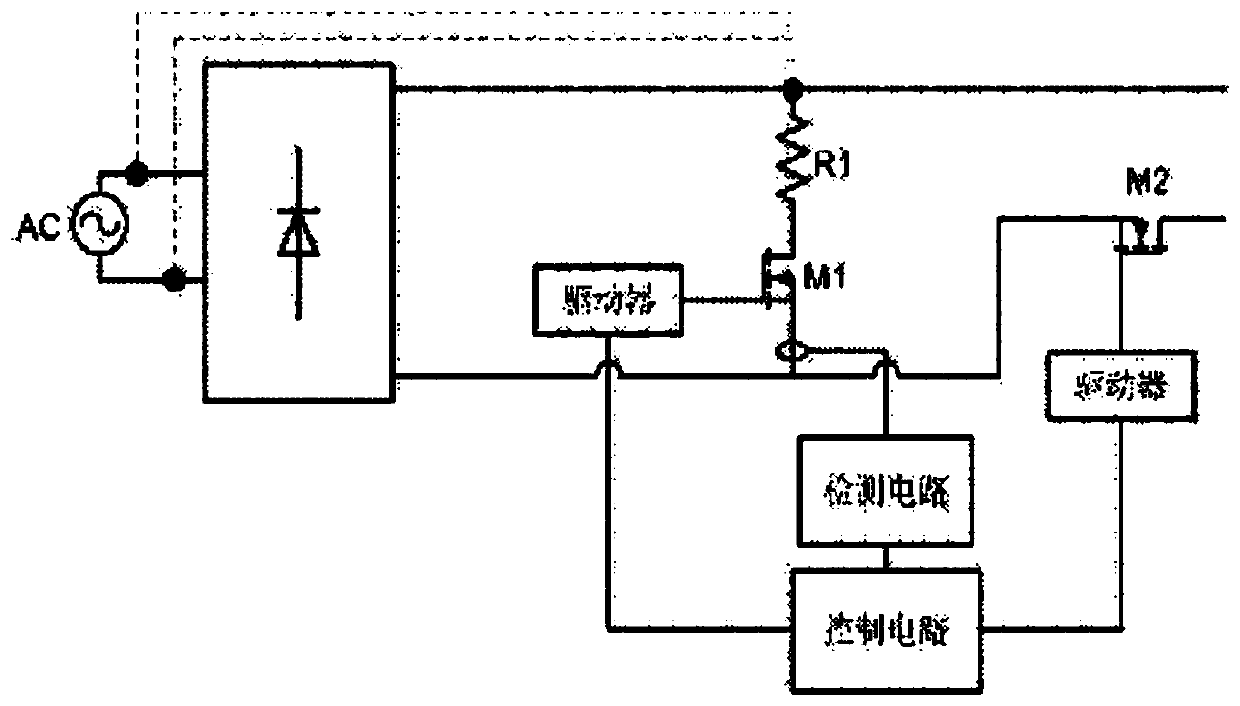

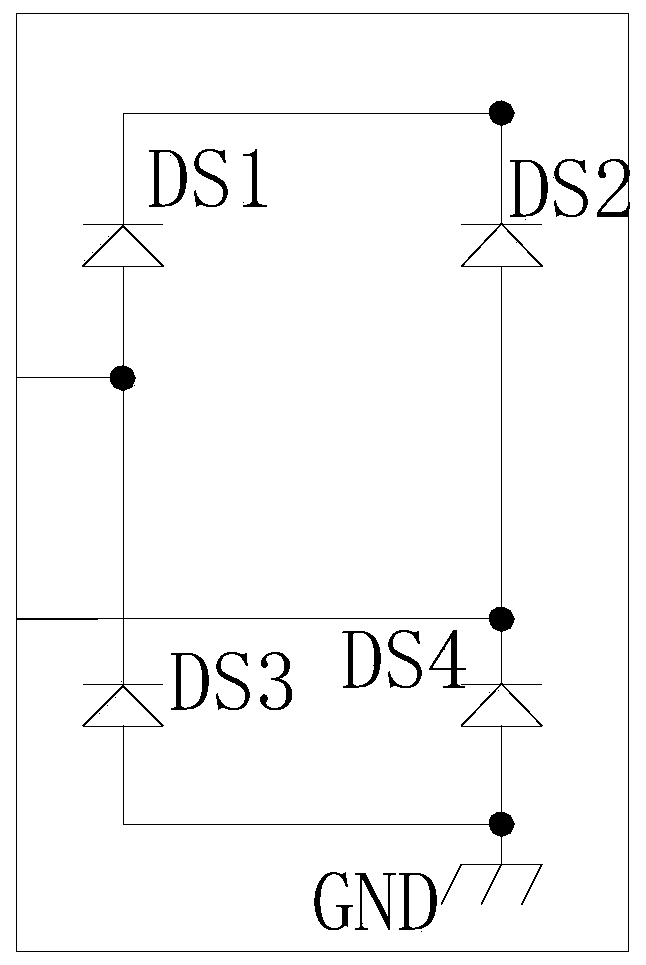

[0035] see Figure 1-6 , the present invention provides the following technical solutions: a lamp compatible with high frequency and power frequency, including a safety protection circuit 1, a rectification circuit 2, an LED drive circuit 3, an electronic ballast drive circuit A, and a leakage current detection protection circuit B1 and a solid IC drive circuit B2, wherein the safety protection circuit 1 is respectively connected to the input terminal L and the input terminal N, and the safety protection circuit 1 is also respectively connected to the rectification circuit 2, the leakage current detection protection circuit B1 and the electronic ballast circuit circuit A , the rectifier circuit 2 is connected to the solid IC drive circuit B2, the leakage current detection protection circuit B1 is connected to the solid IC drive circuit B2, the leakage current detection protection circuit B1 is connected to the LED drive circuit 3, and the electronic ballast loop circuit A is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com