A kind of △5-cholesteryl sulfate compound liposome and its preparation method

A technology of cholesteryl sulfate and compound, which is applied in the field of △5-cholesteryl sulfate compound liposome and its preparation, to achieve the effect of overcoming adverse effects, good dispersion and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

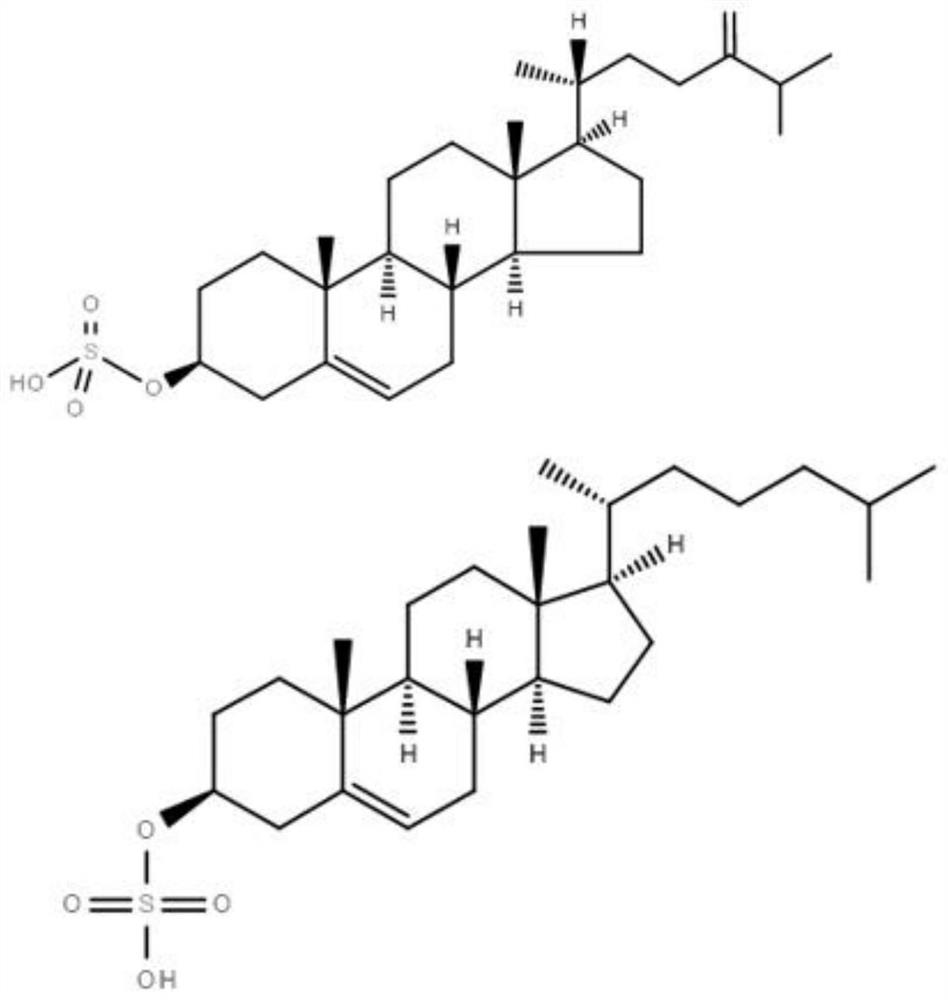

[0029] The representative components of △5-cholesteryl sulfate group are 24-methylene-cholest-5-ene-3β-ol-3-sulfate group and cholest-5-ene-3β-sulfate group. The structural formula is shown in figure 1 , the preparation method is as follows: take the body wall of the aquatic product, grind and sieve after vacuum freeze-drying, add a certain volume of chloroform:methanol solution (2:1, v / v), and keep the total solid-liquid ratio as 1:15 (m / v), continuous stirring and leaching for 24h. After filtering the extract, add 1 / 4 volume of water, fully oscillate and mix, and then let stand to separate layers. After the layers were separated, the lower chloroform layer was removed, concentrated under reduced pressure in vacuo, and dried to obtain the total fat. Take 200-300 mesh silica gel and activate it at 105°C for 10-12 hours, then cool it at room temperature for use, dissolve the total fat in chloroform, mix it with silica gel, pour it into a silica gel column quickly and evenly, ...

Embodiment 2

[0032] Wherein the membrane material components are: 1.0g lecithin and 0.2g Δ5-cholesteryl sulfate compound. All the other are identical with embodiment 1.

[0033] The prepared blank nanoliposomes of △5-cholesteric sulfate group compound is a relatively transparent light yellow solution with an average particle diameter of 107.3nm and a dispersion coefficient of 0.193. It has good stability and can be stored for more than 10 days at 4°C. Equal stability to cholesterol blank liposomes.

Embodiment 3

[0035] Application of a kind of embodiment 1 liposome in drug delivery system:

[0036] Accurately weigh 0.6g of lecithin, 0.2g of △5-cholesteric sulfate group compound and 20mg of astaxanthin, completely dissolve in 12mL of dichloromethane, and remove the dichloromethane by vacuum rotation in a water bath at 40°C. A uniform lipid film was formed on the Add 20 mL of normal saline solution, place it in an ultrasonic cell disruptor and sonicate to obtain a deep red suspension, namely the crude liposome suspension of △5-cholesteryl sulfate compound encapsulating astaxanthin. The crude liposome suspension was centrifuged at 10000 g for 10 min to remove impurities that did not form liposomes in the system. The supernatant is the prepared astaxanthin-encapsulating △5-cholesteric sulfate compound nanoliposome. The prepared △5-cholesteric sulfate nanoliposomes encapsulating astaxanthin is a deep red solution, with an average particle diameter of 110.3nm, a dispersion coefficient of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com