Railway vehicle vertical combined type glass installation supporting device

A technology for rail vehicles and supporting devices, which is applied in the installation of window glass, window device, workpiece clamping device, etc., can solve the problems such as glass does not slide down, bonding strength cannot be guaranteed, etc., and achieves convenient operation, light weight and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

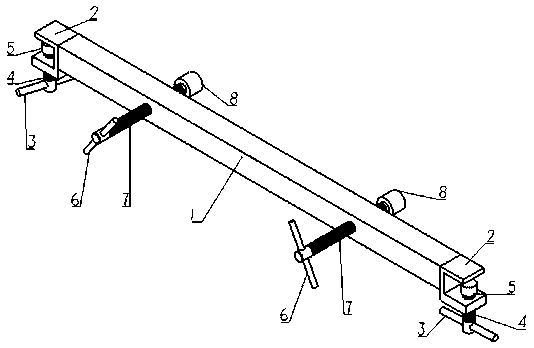

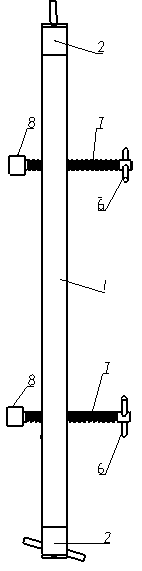

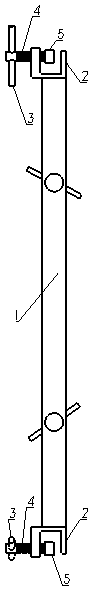

[0021] A rail vehicle upper and lower combined glass installation support device, including a pipe body 1, an upper positioning clamping device, a lower positioning clamping device, an upper screw lifting device and a lower screw lifting device, an upper positioning clamping device and a lower positioning clamping device The upper and lower ends of the pipe body 1 are respectively fixedly arranged, and the upper screw lifting device and the lower screw lifting device are installed at the middle end of the pipe body 1 .

[0022] Further, the upper positioning clamping device includes a chuck 2, a handle 3, a screw 4 and a pressure head 5, the chuck 2 is fixedly arranged on the front end of the pipe body 1, the shape of the chuck 2 is U-shaped, and the lower end of the chuck 2 is opened Cooperate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com