Multi-gold-sheet multi-combination sheet feeding device and embroidery machine

A sequin feeding technology, which is applied in the field of sequin embroidery machines, can solve problems such as the inability to achieve multiple specifications of sequins with one needle and four stacks, and the limitation of gold plate specifications, so as to save installation space and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

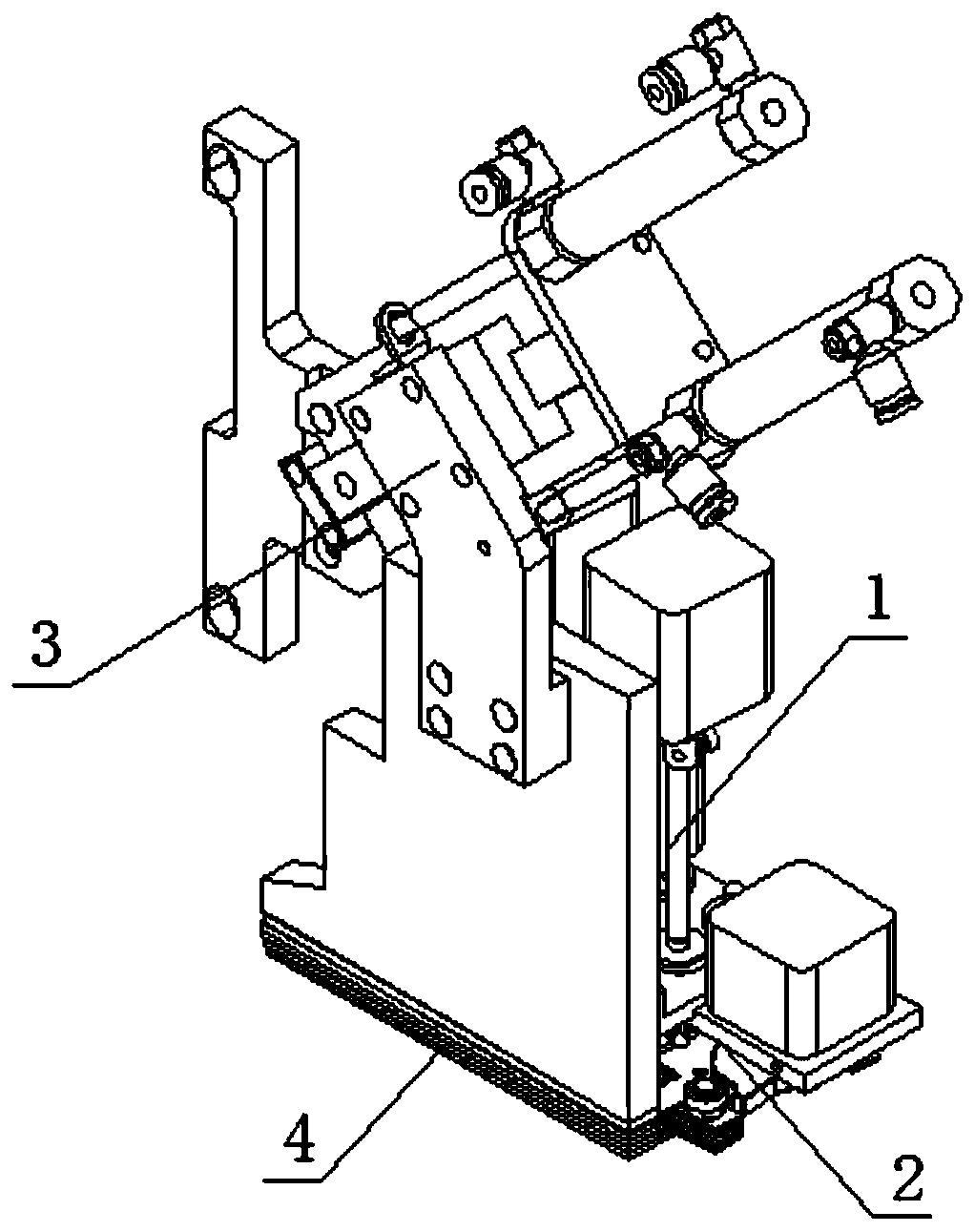

[0040] Such as Figure 1 to Figure 10 As shown, the sequin embroidery device for multi-sequin multi-combination feeding includes:

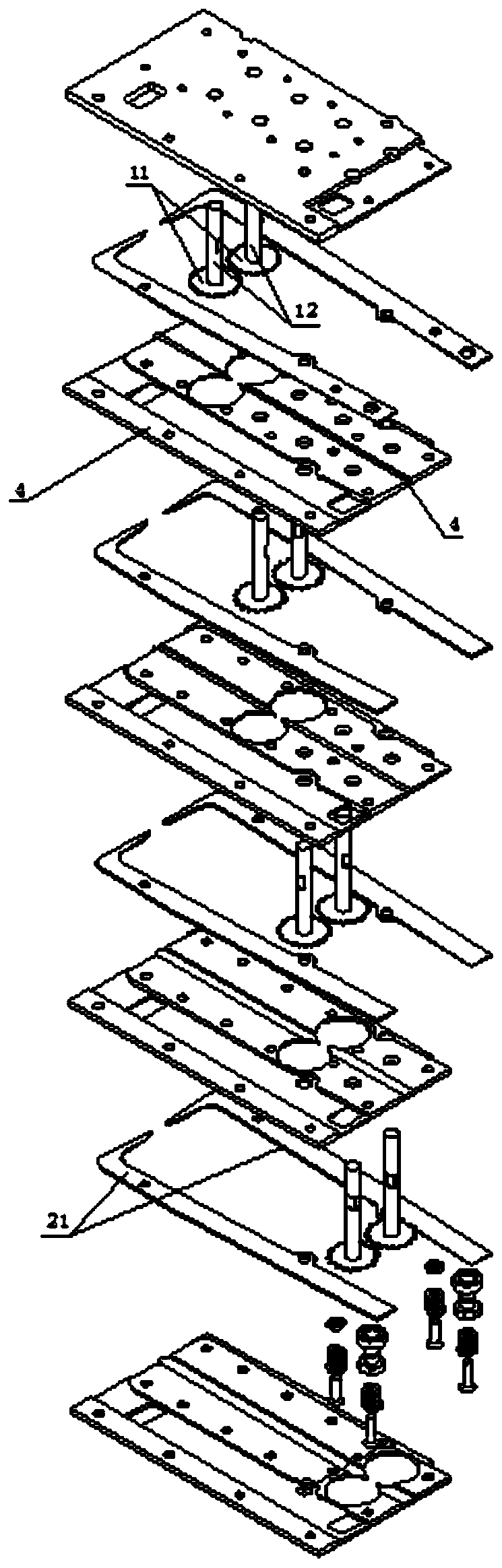

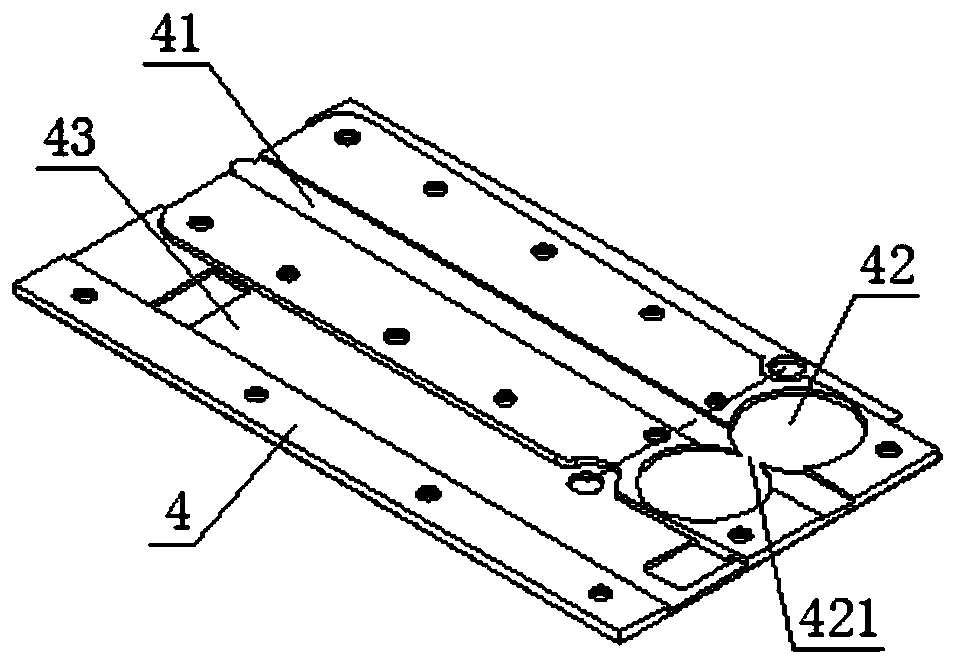

[0041] A gold sheet separator 4, a plurality of the gold sheet separators 4 are stacked to form a gold sheet separator assembly, and a gold sheet conveying channel is arranged between two adjacent gold sheet separators 4, thus forming a multi-layer structure along the height direction The gold flake conveying channel, the horizontal projection of the center line of the gold flake conveying channel of all layers coincides, so that the conveyed gold flakes form the effect of multi-layer lamination;

[0042] The sheet conveying assembly 1 includes sheet conveying rollers 11, and a group of sheet conveying rollers 11 is correspondingly arranged for each gold sheet conveying channel, and each group of sheet conveying rollers includes two sheet conveying rollers 11 symmetrically arranged on both sides of the width of the gold sheet conveying passage, A...

Embodiment 2

[0073] The embroidery machine includes the sequin embroidery device with multiple sequins and multi-combination feeding pieces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com