Small submersible pond sludge sucking device

A submersible, pond technology, used in earthmovers/shovels, mechanically driven excavators/dredgers, construction, etc., can solve problems such as troublesome implementation, slow equipment work, inconvenient movement in water, etc., to avoid blockages Sludge pump, the effect of reducing the diffusion area and reducing the turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

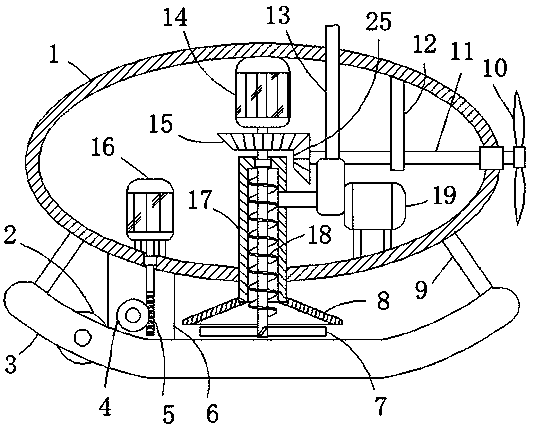

Embodiment 1

[0023] Embodiment 1: A small-sized submersible pond suction device, including a sludge pump 19 and a housing 1 with an arc-shaped structure. The center of the inner wall of the lower end of the housing 1 is fixedly connected with a fixed block 17 through a mounting hole, and the lower end of the fixed block 17 is opened. There is a cylindrical groove, and a stirring structure is arranged in the cylindrical groove. The input end of the sludge pump 19 is fixedly connected with a connecting pipe, and one side of the fixed block 17 is fixedly connected with the nozzle of the connecting pipe through a round hole, and the connecting pipe communicates with the cylindrical groove , the upper end of the housing 1 is fixedly connected with an output pipe 13 through a through hole, the lower end of the output pipe 13 passes through the through hole and is fixedly connected with the output end of the sludge pump 19, and the power input end of the sludge pump 19 is connected through a wire a...

Embodiment 2

[0025] Embodiment 2: the difference based on Embodiment 1 is;

[0026] The agitating mechanism includes a rotating shaft arranged in the cylindrical groove, the upper end of the rotating shaft is rotationally connected with one side of the cylindrical groove through the second sealed bearing, the shaft wall of the rotating shaft is fixedly connected with a helical blade 18, and the inner wall of the upper end of the housing 1 is fixed The first motor 14 is connected, and the power input end of the first motor 14 is electrically connected to the external power supply through wires and control switches. This technology has been widely used in daily life, and those skilled in the art should know it, so it will not be done again. More details, the end of the output shaft of the first motor 14 passes through the first sealed bearing and is fixedly connected with the upper end of the rotating shaft, the output shaft of the first motor 14 is fixedly connected with the second bevel gea...

Embodiment 3

[0029] Embodiment 3: the difference based on embodiment 1 is;

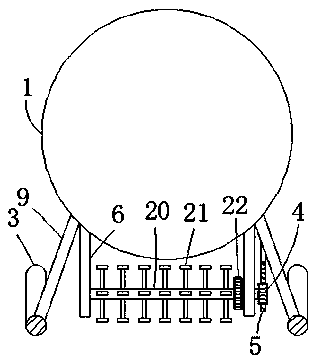

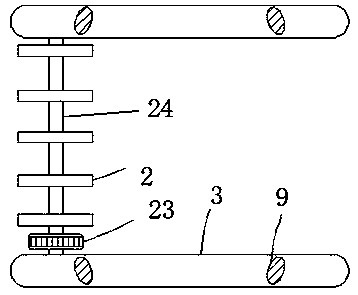

[0030]The pulverizing mechanism includes a stirring shaft 20 which is rotatably connected between the two mounting plates 6 through a first rolling bearing. The shaft wall of the stirring shaft 20 is fixedly connected with a plurality of evenly distributed crushing blades 21, and the plurality of crushing blades 21 are T-shaped. structure, one end of the stirring shaft 20 passes through the first rolling bearing and is fixedly connected with the worm wheel 4, the worm wheel 4 is meshed with the worm 5, the upper end of the worm 5 is rotationally connected with the lower side of the housing 1 through the third sealed bearing, the housing 1 The inner wall of the lower end is fixedly connected with a second motor 16, and the power input end of the second motor 16 is electrically connected with an external power supply through a wire and a control switch. To repeat too much, the output end of the second motor 16 passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com