Temperature transmitter fixing device

A technology for temperature transmitters and fixing devices, applied in the direction of supporting machines, mechanical equipment, machine platforms/supports, etc., can solve problems such as shaking, detection deviation, damage, etc., and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

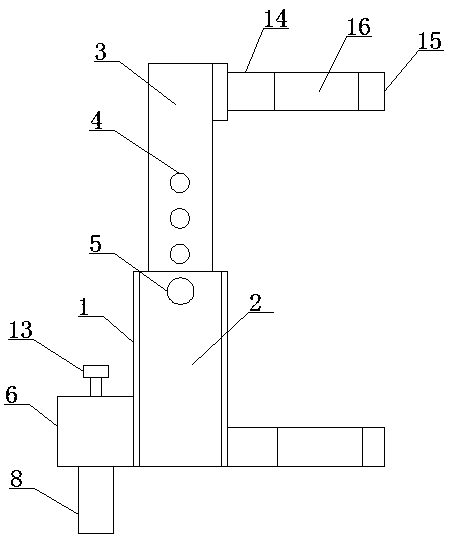

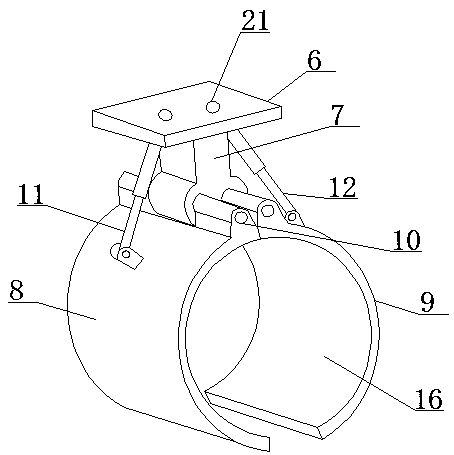

[0024] like Figure 1-3 As shown, the fixing device of the integrated temperature transmitter according to the embodiment of the present invention includes a cylinder body 1 and a limit sleeve 2 located at the inner bottom end of the cylinder body 1, and the limit sleeve 2 is provided with an extension To the column 3 at the top of the cylinder 1, one side of the column 3 is provided with a number of evenly distributed limiting grooves 4, and one side of the cylinder 1 is provided with tight fittings extending into the limiting groove 4. Fasten the bolt 5, the bottom end of one side of the cylinder 1 is provided with a side plate 6, the bottom end of the side plate 6 is provided with a connecting block 7, and the bottom end of the connecting block 7 is symmetrically provided with a fixed piece 8 and The second fixed piece 9, the first fixed piece 8 and the second fixed piece 9 are respectively connected to the connecting block 7 through the rotating shaft 10, the side of the f...

Embodiment 2

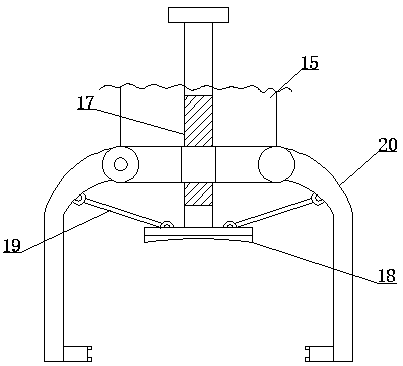

[0026] like Figure 1-3 As shown, the clamping mechanism 15 includes a hole 16 located on the horizontal plate 14, the hole 16 is provided with a threaded rod 17 passing through the horizontal plate 14, and the other threaded rod 17 is The side is provided with push plate 18, and the top two sides of described push plate 18 are symmetrically provided with the connecting rod 19 that obliquely arranges, and the other side of described connecting rod 19 is provided with clamping rod 20, and the top of described clamping rod 20 Both are connected to the horizontal plate 14, the clamping rod 20 is an arc structure, and the clamping rod 20 is connected to the horizontal plate 14 through a roller.

Embodiment 3

[0028] like Figure 1-3 As shown, the bottom end of the push plate 18 is provided with an arc-shaped groove, and a rubber cushion is provided in the arc-shaped groove, and the side plate 6 and the connecting block 7 are provided with a 11 and the threaded groove 21 that matches the threaded rod two 12, the side of the fixed piece one 8 and the fixed piece two 9 that are close to each other are provided with a matching flexible layer, located at the top of one side of the column 3 The said transverse plate 14 is connected with it by a backing plate. It is not difficult to see from the above design that the design of the rubber cushion can better protect the outer wall of the device from being scratched.

[0029] In order to facilitate the understanding of the above-mentioned technical solution of the present invention, the working principle or operation mode of the present invention in the actual process will be described in detail below.

[0030] In actual application, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com