Method for determining leakage pollution range of hazardous chemical substance

A determination method and technology for hazardous chemicals, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as non-existence and inability to determine the range of steam clouds, and achieve easy to master, high calculation accuracy, and data visualization. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

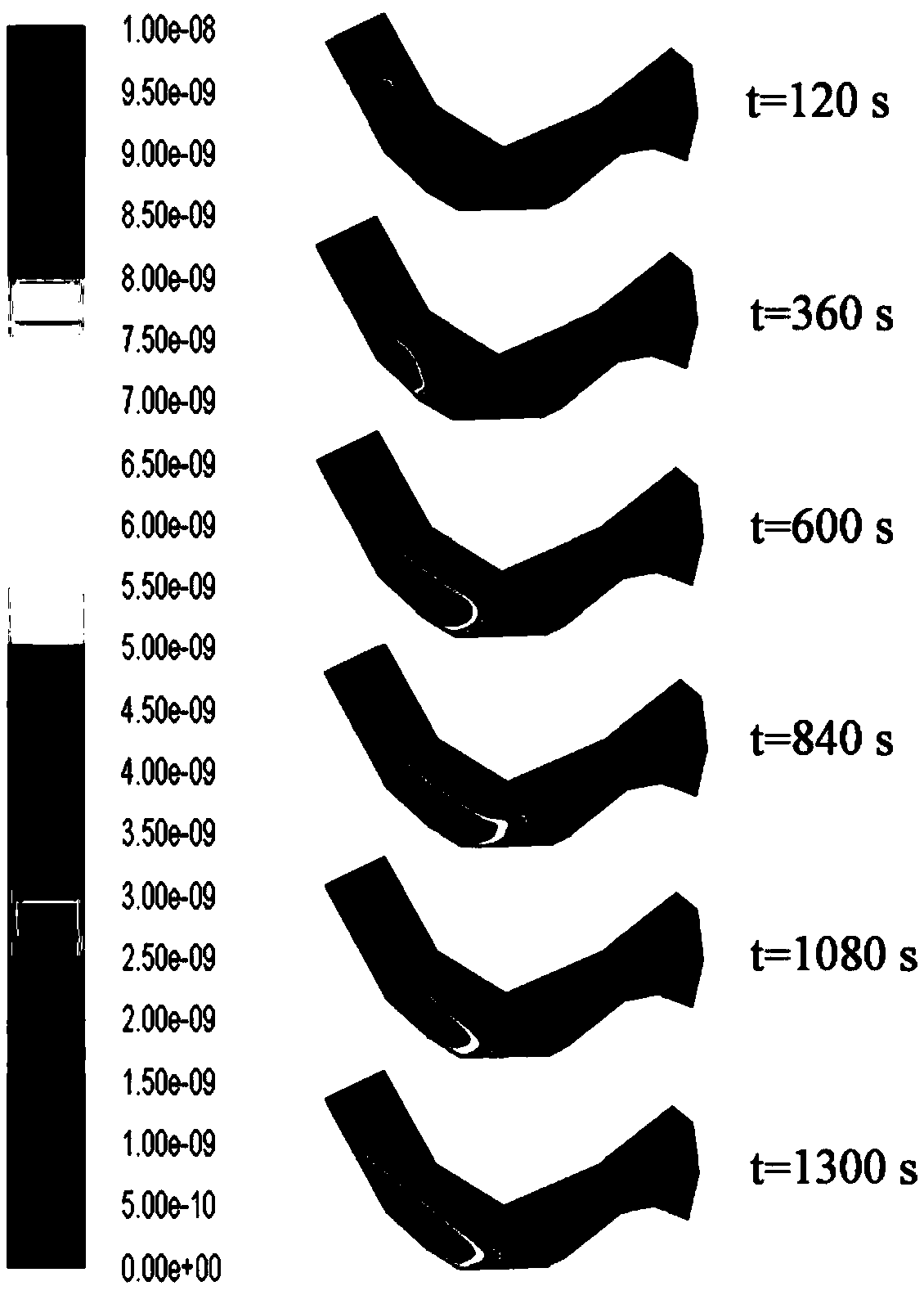

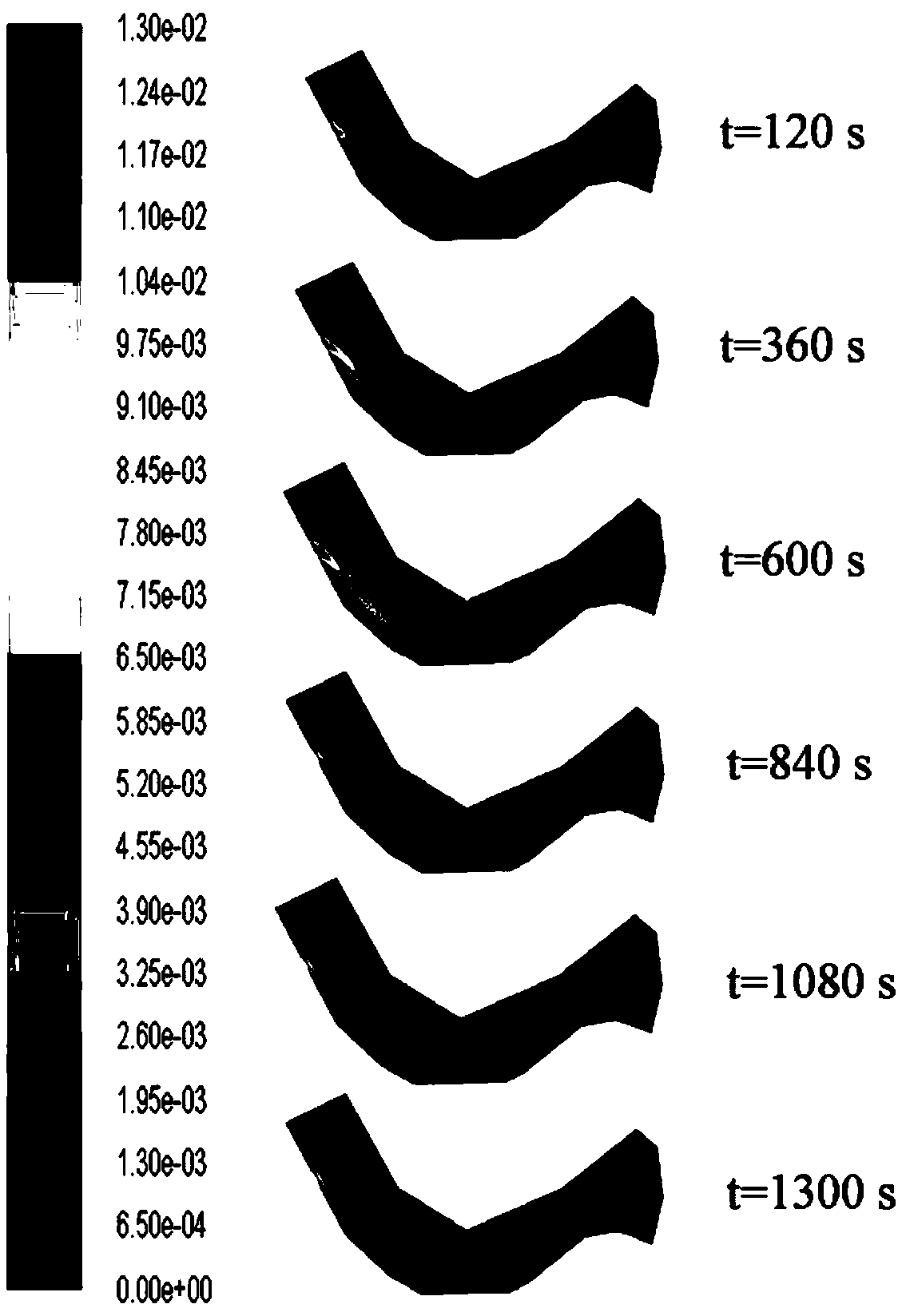

[0040] A method for determining the scope of pollution from leakage of hazardous chemicals, comprising the following steps:

[0041] s1. Determine the simulation scenario, and obtain the meteorological and hydrological information, geographical feature information and leakage source information of the area where the leakage accident occurred.

[0042] Among them, the meteorological and hydrological information includes wind speed, wind direction, air pressure, water flow distribution and water flow velocity.

[0043] Wherein, the geographic feature information includes a contour map.

[0044] Among them, the leakage source information includes equipment or pipeline operating parameters, design parameters and physical parameters of the leakage material.

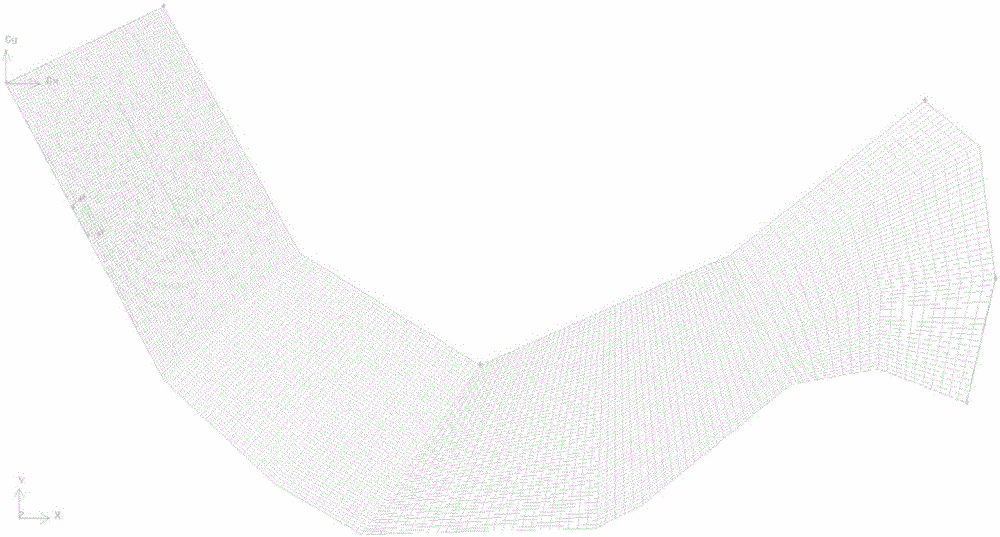

[0045] s2. Establish a three-dimensional geometric model of the area near the leakage source and perform grid division.

[0046] The purpose of grid division is to make the model into a finite element. After the grid is divi...

Embodiment 2

[0058] This embodiment 2 describes a method for determining the scope of leakage of hazardous chemicals. Except for the following technical features that are different from the above-mentioned embodiment 1, other technical features of this method can refer to the above-mentioned embodiment 1.

[0059] This embodiment 2 also provides the basic principle of grid division in step 2, as follows:

[0060] If the geometric shape of the 3D geometric model is relatively regular, select the structured grid;

[0061] If the geometric shape of the 3D geometric model is irregular, the structured grid is divided into blocks or the unstructured grid is used as a whole.

[0062] The benefits of the above meshing are:

[0063] When the geometric shape is relatively regular, it can be divided into structured grid or unstructured grid. Compared with unstructured grid, structured grid has faster calculation speed and fewer grids.

[0064] However, the division of irregularly shaped geometric mo...

Embodiment 3

[0066] This embodiment 3 describes a method for determining the scope of leakage of hazardous chemicals. Except for the following technical features that are different from the above-mentioned embodiment 1 or 2, other technical features of this method can refer to the above-mentioned embodiment 1 or 2.

[0067] In this embodiment 3, in step s3, after importing the mesh into the fluid flow module in the finite element analysis software, it is necessary to check the quality of the mesh. Negative volumes cannot appear, and if so, re-mesh to ensure the mesh quality The quality meets the requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com