Storage battery fixing frame

A fixing frame and battery technology, which is applied to battery pack components, circuits, electrical components, etc., can solve the problems of battery loosening, displacement power failure, and the circuit cannot achieve a safe explosion-proof type, and achieves reliable and simple fixed structure. , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

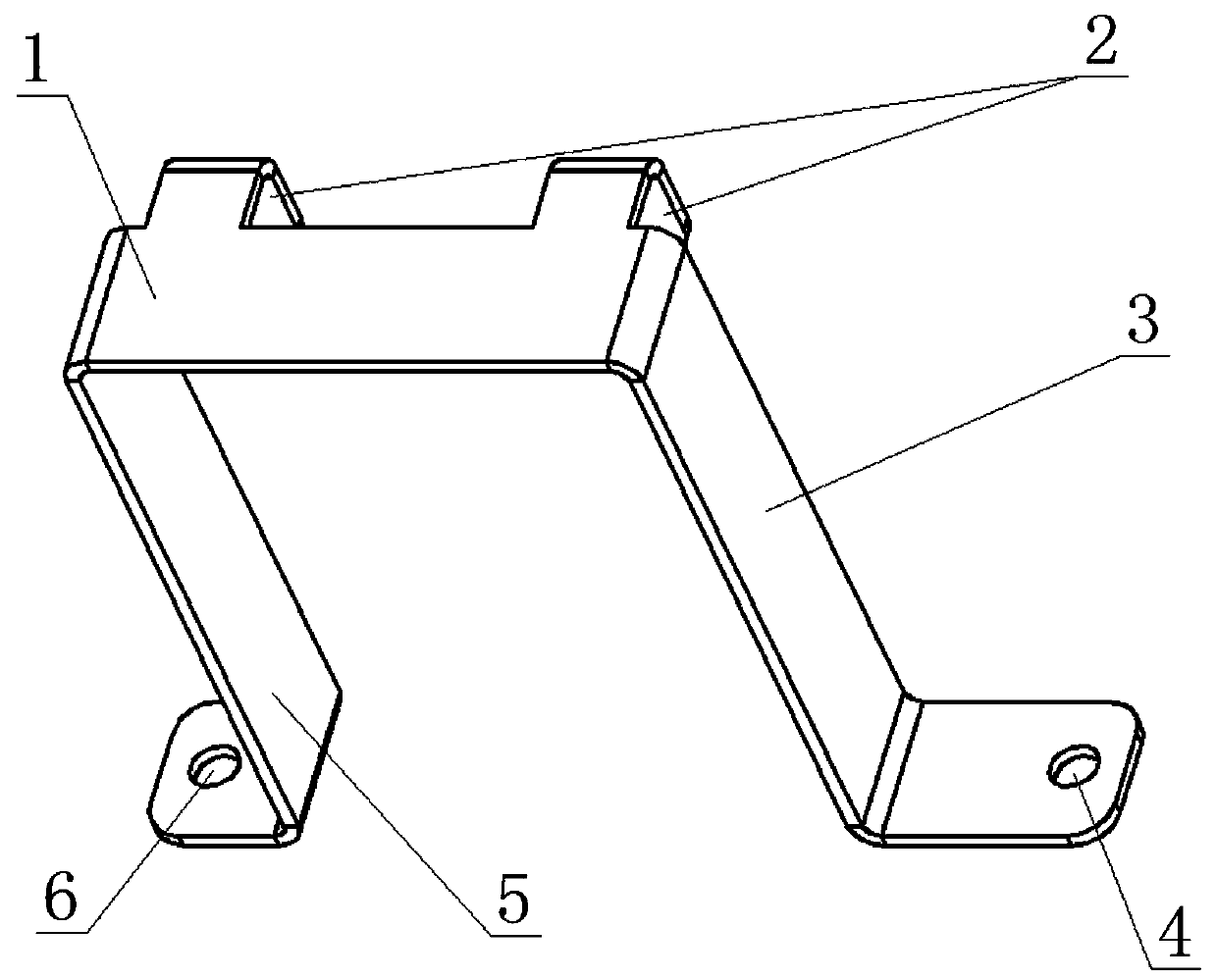

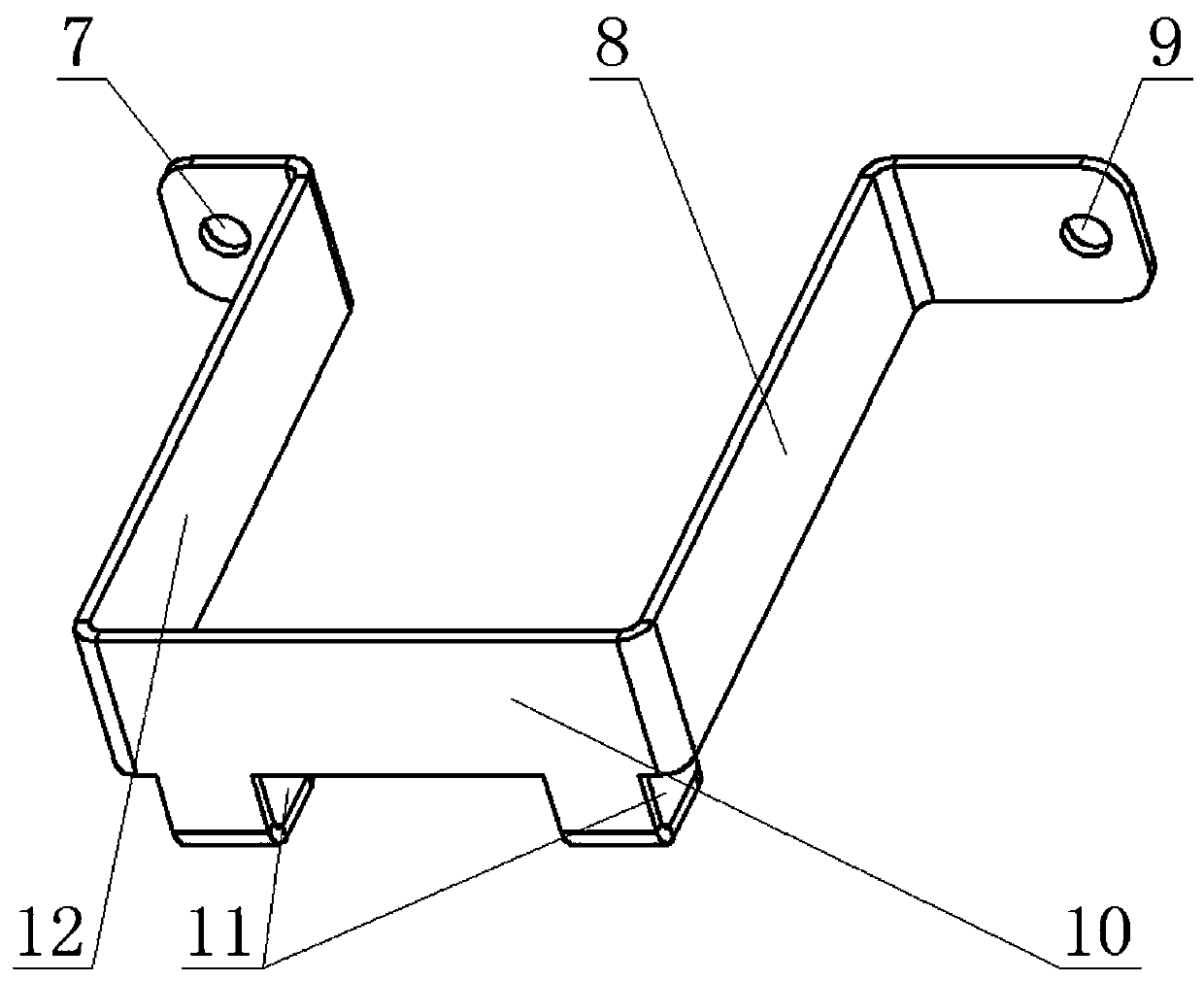

[0013] A battery fixing frame, comprising an upper frame beam 1 and a lower frame beam 10; it is characterized in that: the upper frame beam 1 and the lower frame beam 10 have a U-shaped structure; the upper frame beam 1 includes a bottom plate of the upper frame beam 1 and a left side plate 5 of the upper frame The upper shelf right side plate 3; the lower shelf beam 10 includes the lower shelf beam 10 bottom plate, the lower shelf left side plate 12, and the lower shelf right side plate 8; the upper shelf limit hook 2 is provided on the side of the upper shelf beam 1 bottom plate, and the lower shelf The bottom plate of the beam 10 is provided with a lower shelf limit hook 11; the top of the left side plate 5 of the upper shelf and the right side plate 3 of the upper shelf are all provided with an upper shelf fixing plate; and the mounting hole 4 on the right side of the upper frame; the top of the left side plate 12 of the lower frame and the right side plate 8 of the lower ...

Embodiment 2

[0015] The technical solution adopted in the present invention is: the positioning storage battery fixing frame is divided into an upper shelf and a lower shelf. The upper frame adopts a U-shaped frame structure, and two limit hooks are designed on the upper part of the U-shaped frame; the lower frame also adopts a U-shaped frame structure, and two limit hooks are designed on the lower part of the U-shaped frame. The battery is placed between the upper shelf and the lower shelf, the U-shaped shelf structure is positioned left and right and up and down, and the upper and lower sets of limit hooks are positioned front and back.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com