A fully automatic anti-electric shock pole climbing device for electric power engineering maintenance

A technology of electric power engineering and electric shock prevention, applied in the direction of climbing, sports accessories, etc., can solve problems such as difficulty in implementation, difficulty in work, etc., and achieve the effects of careful and safe maintenance, simple structure, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

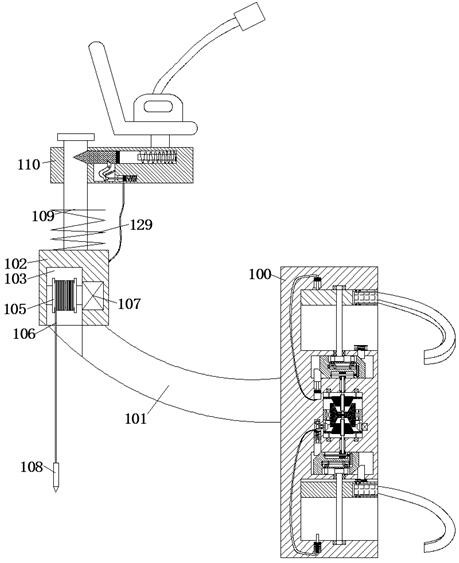

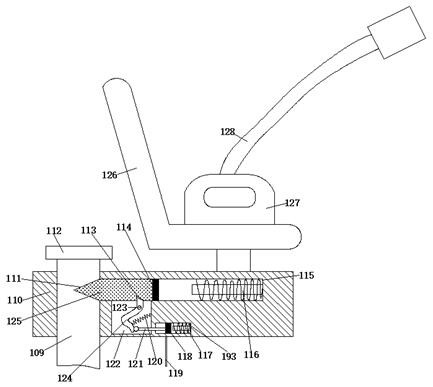

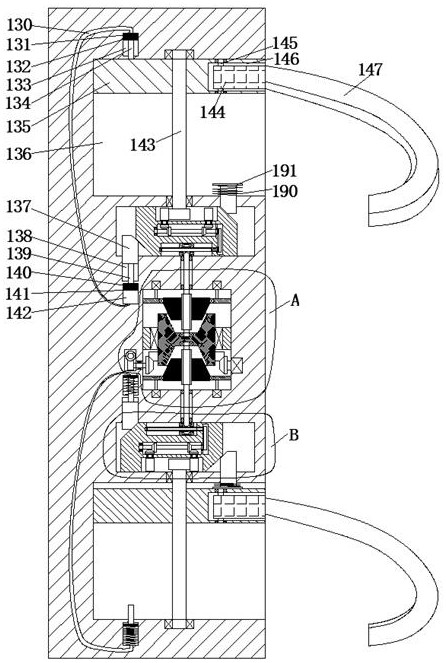

[0036] see Figure 1-7 , a fully automatic anti-shock electric pole climbing device for electric power engineering maintenance, which includes a climbing body 100, a support frame 101, a support body 102 and an electric shock-proof seat 110, and the middle part of the left end of the climbing body 100 is fixedly connected with a support frame 101 , the support frame 101 is curved, the other end of the support frame 101 is fixedly connected with a support body 102, and the top of the support body 102 is fixedly connected with a front and back symmetrical fixed guide column 109, and the fixed guide column 109 is sleeved with an electric shock-proof seat 110. The top of the body 102 is provided with a shock-absorbing spring 129 surrounding the fixed guide column 109, and the right end of the climbing body 100 is dug with a vertically symmetrical first chute 136, and the first chute 136 is provided with a power direction conversion groove near the center end of the climbing body 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com