A method for reverse control of neutron action in injection molding machine

A reverse control, injection molding machine technology, applied in the field of injection molding machines, can solve the problems of complicated operation process, oil leakage at the connection of oil pipes, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

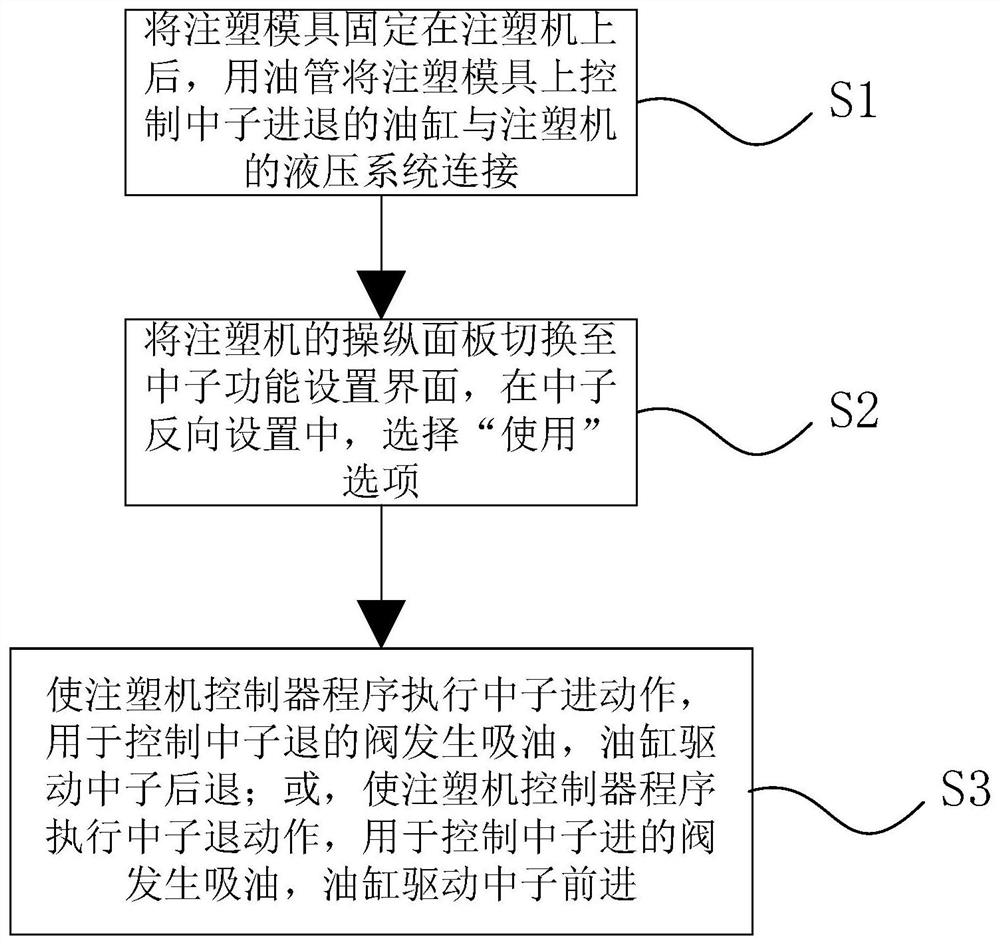

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

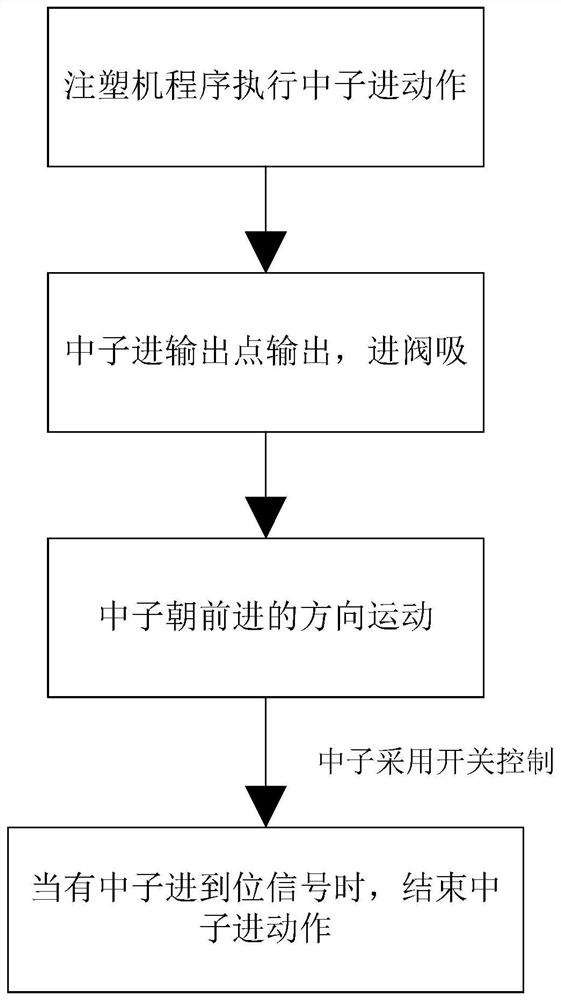

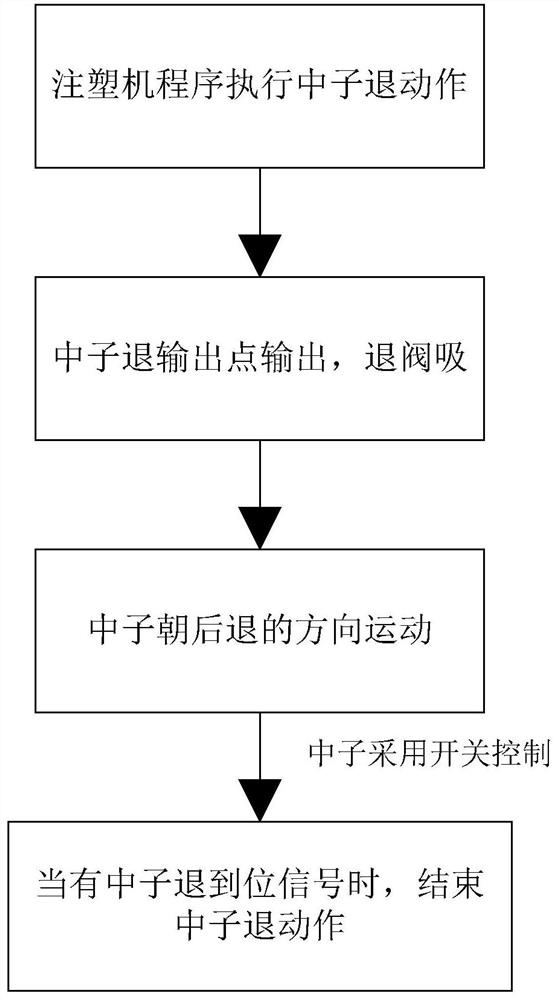

[0033] For some plastic products with relatively complex structures, flat molds alone cannot be formed. For example, the formation of side holes, side grooves and other structures must be formed by setting a slider mechanism on the injection mold; and the movement of the slider is divided into oblique guides There are two types of column drive and oil cylinder drive. Compared with the inclined guide column drive, the oil cylinder drive has the advantages of stable operation, strong core pulling force, and is not easy to jam the slider. An oil cylinder is installed at the end of the slider, and the oil cylinder is connected to the hydraulic system of the injection molding machine through the oil pipe. By controlling the expa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com