Waste ink conveying device and image forming device

A conveying device, waste ink technology, applied in the direction of inking device, printing device, printing, etc., can solve the problems of leakage, pollution around, faulty waste ink, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

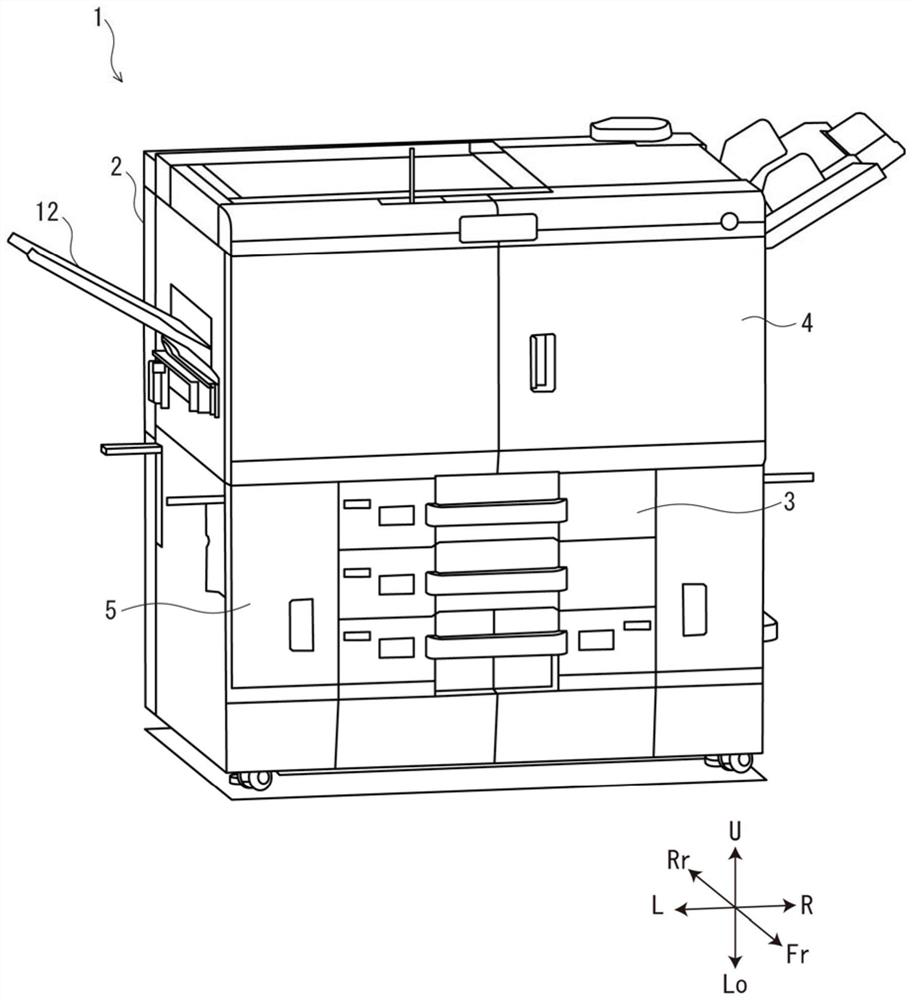

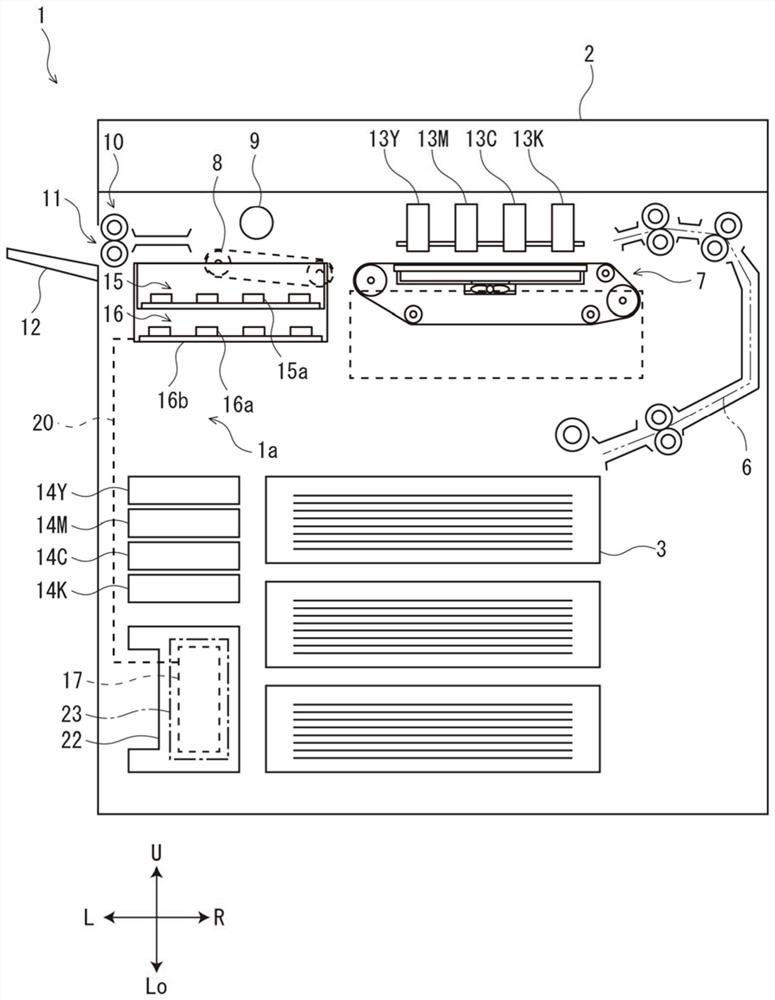

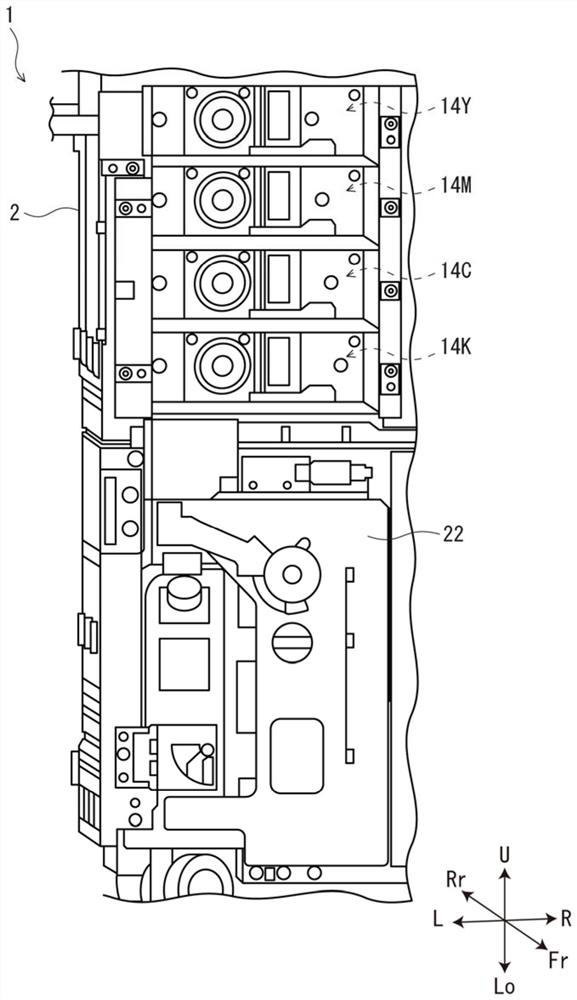

[0046]First,figure 1 withfigure 2 The overall configuration of the printer 1 of the inkjet image forming apparatus according to the first embodiment of the present invention will be described. Below, in order to facilitate explanation,figure 1 The paper surface is close to the front side of the printer 1. The arrows FR, RR, L, R, U, LO, which are suitable in each diagram, indicate the front side of the printer 1, the rear side, the left, the right side, the upper and lower side, respectively.

[0047]Such asfigure 1 withfigure 2 As shown, the printer 1 has a printer main body 2 of a box type shape. At the lower part of the printer body 2, the paper feed cassette 3 containing the storage paper can be contained.

[0048]At the front surface of the printer main body 2, the upper cover 4 and the lower left side cover 5 are provided in a manner that can be opened. By opening the upper side cover 4, the paper conveying unit 7, the end cap unit 15, and the wiping unit 16 are maintained. In addit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com