High-performance autoclaved aerated concrete slab parapet structure of prefabricated building

A technology of autoclaved air filling and concrete slabs, which is applied to building structures, building components, buildings, etc., can solve the problems of weakened structural rigidity and stability, failure to achieve fireproof and heat preservation effects, etc., to improve structural stability and overall The effect of reliable structure quality and stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

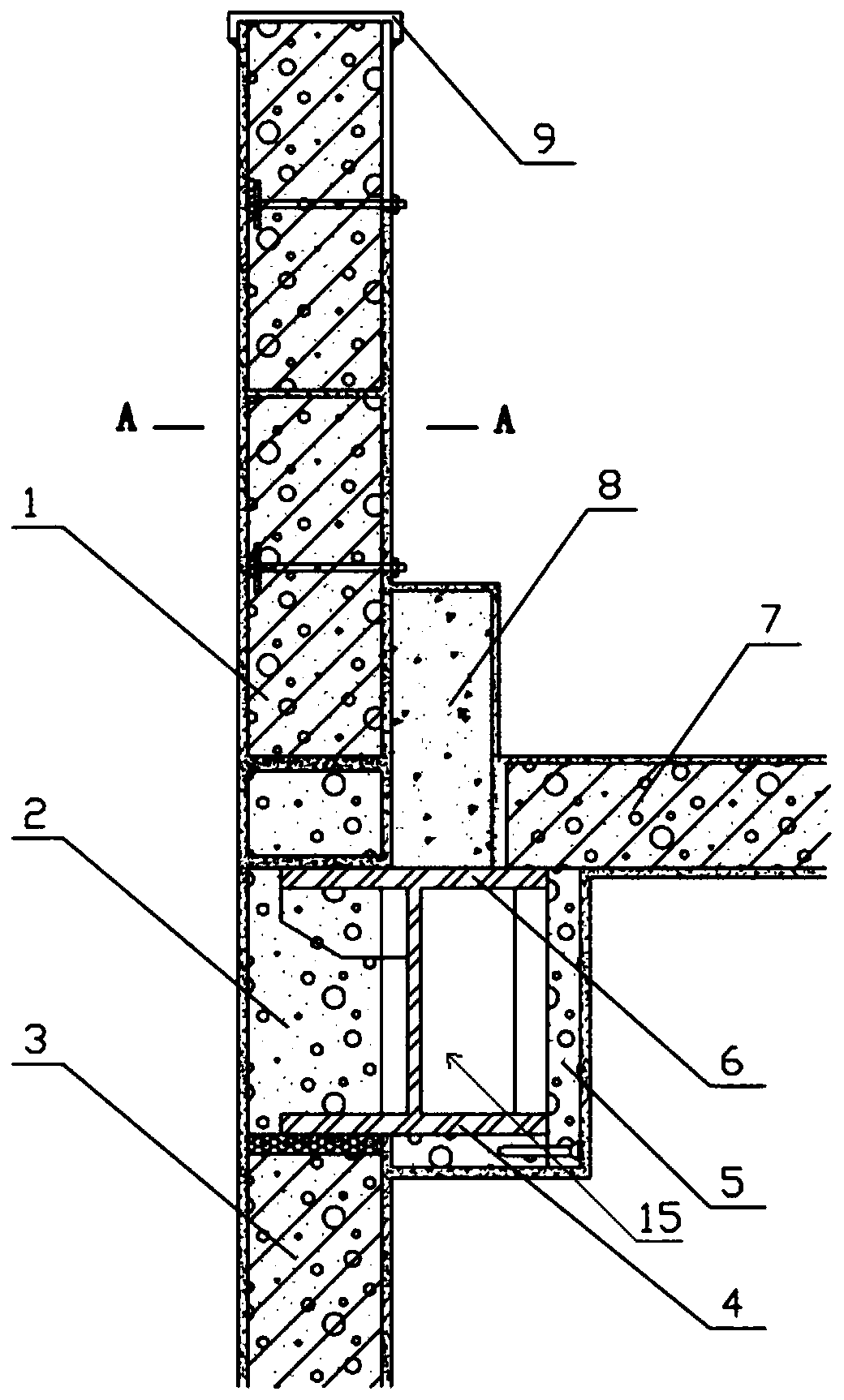

[0030] see figure 1 As shown, the embodiment of the present invention provides a high-performance autoclaved aerated concrete slab parapet structure for a prefabricated building, including a parapet, a wall panel assembly and a third connector 15, wherein the parapet includes a plurality of prefabricated parapets Wall panel 1, the end of the assembled parapet panel 1 is provided with a first connector, here specifically refers to the ends of the two adjacent assembled parapet panels 1 being provided with a first connector. The assembled parapet panel 1 is provided with a first connecting piece only at one end near the inner wall; at least one second connecting piece is provided between each left and right adjacent assembled parapet panel 1, and the second connecting piece It is used to connect the two first connectors in the ends of the corresponding two adjacent assembled parapet panels 1, connect multiple assembled parapet panels 1 to form a whole parapet, and keep the overa...

Embodiment 2

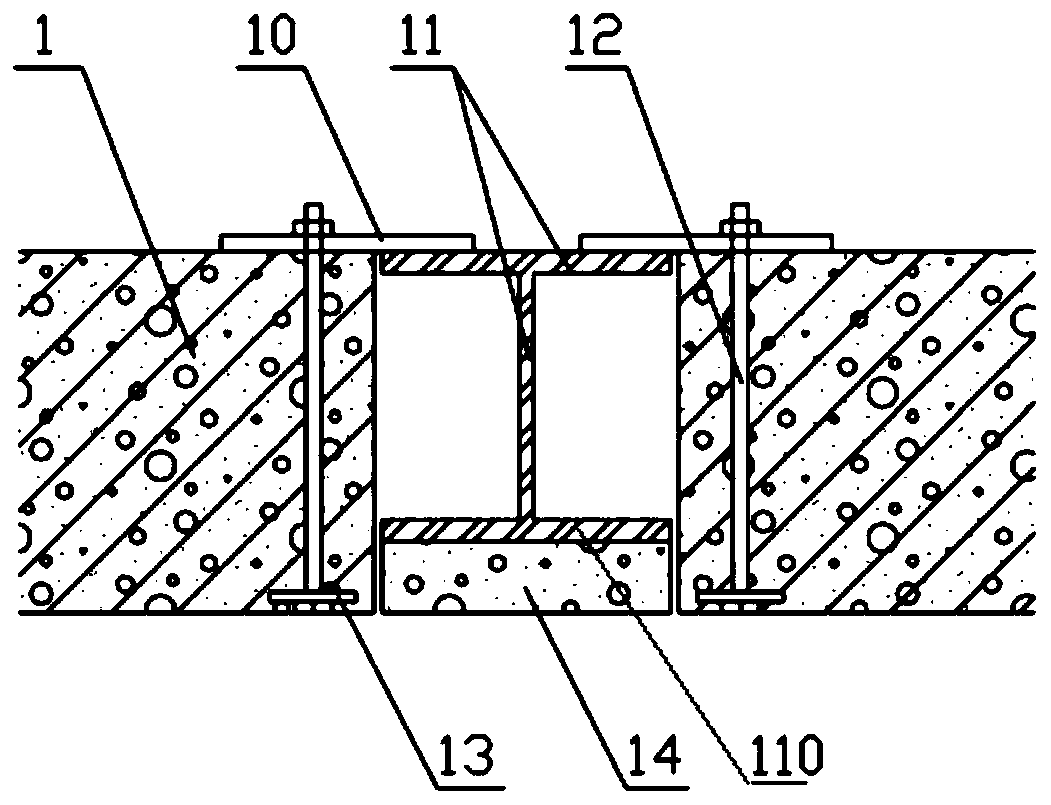

[0036] The present invention also provides an embodiment, see figure 1 , figure 2 , the present invention is a high-performance autoclaved aerated concrete slab parapet structure for prefabricated buildings. It is composed of high-performance autoclaved aerated concrete panels with internal reinforcement. The parapet is a whole composed of prefabricated parapet panels 1, and I-shaped panels are installed between the ends of adjacent prefabricated parapet panels. Type structural steel column 11; bolted iron parts 13 are welded on the reinforcement main reinforcement inside the end of the assembled parapet panel 1, and the iron parts 13 are connected with the steel plate connector 10 and the bolt 12 by bolts during installation, and the steel plate is connected at the same time Part 10 is welded with the wing plate in the I-shaped structural steel column 11 to form an integral parapet structure of the prefabricated building; the exposed part of the I-shaped structural steel co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com