Buffer structure of spring bolt of lock

A buffer structure and lock body technology, which is applied in building locks, building construction, construction, etc., can solve problems such as component damage, affecting service life, and noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

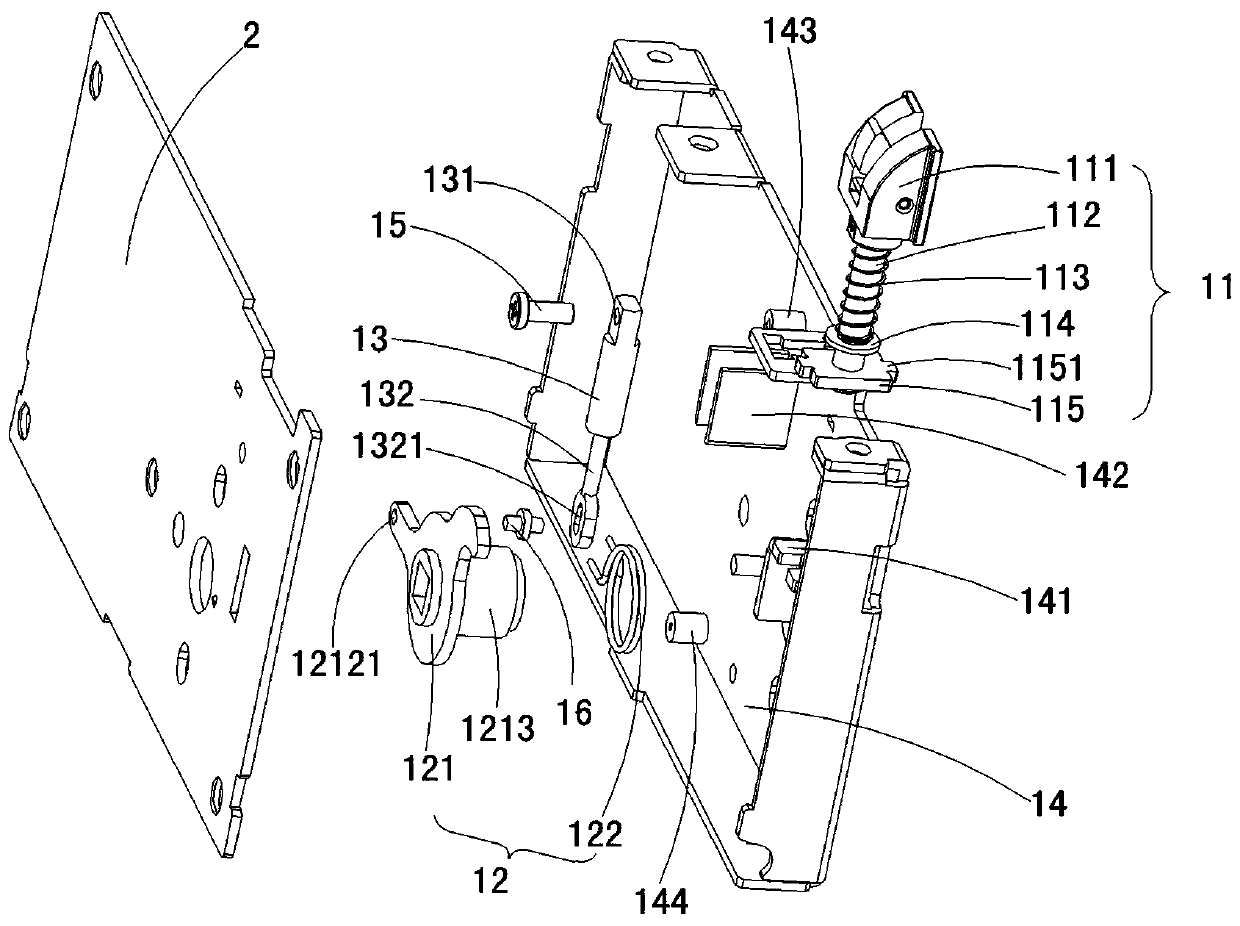

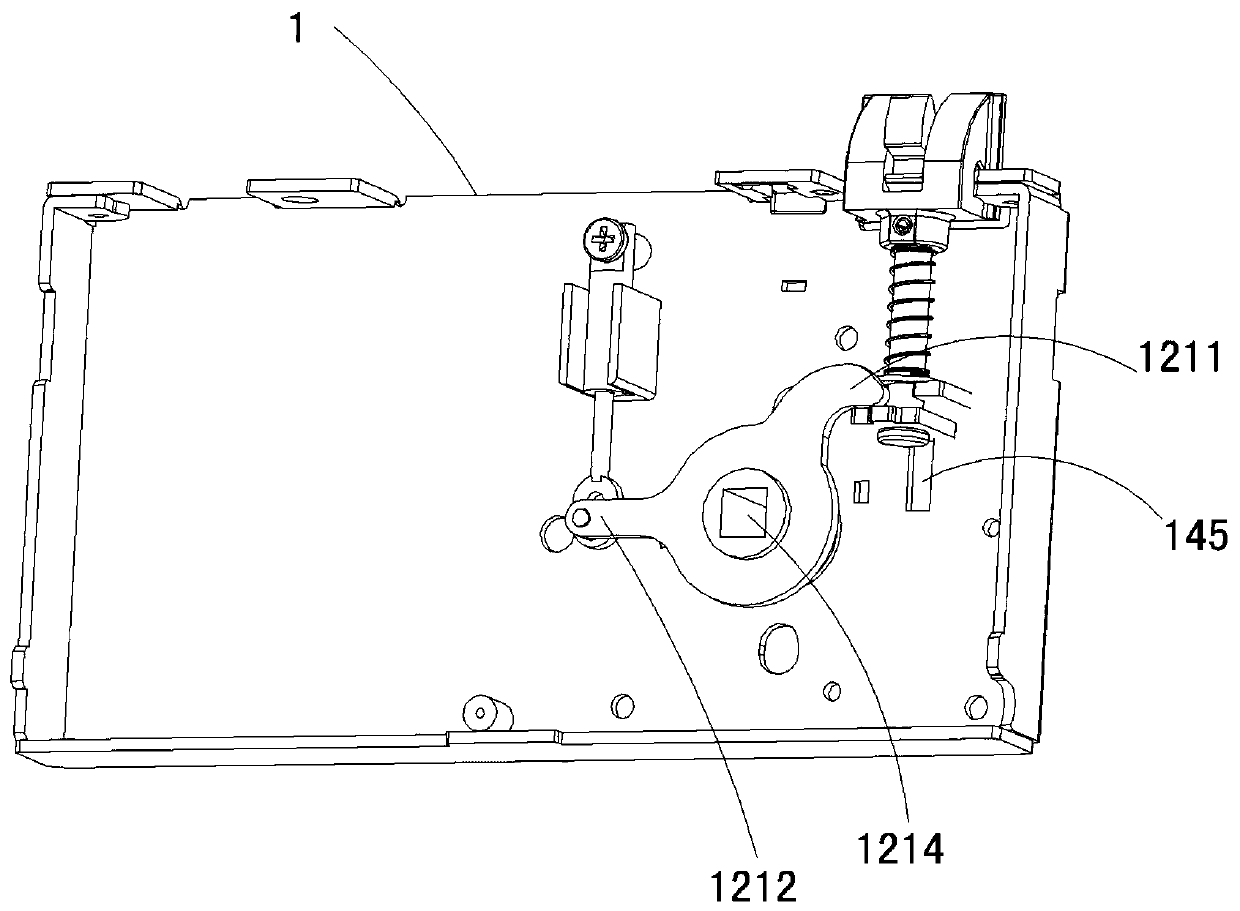

[0015] A lock body bolt buffer structure, including a box bottom assembly 1 and a lock body upper cover 2, characterized in that: the box bottom assembly 1 includes a bolt assembly 11, a bolt bolt assembly 12, a damper 13 and a box body 14. The latch bolt assembly 11 includes a latch bolt 111, a latch bolt pull rod 112, a latch bolt spring 113, a washer 114 and a shifting block 115, and two ends of the shifting block 115 are provided with sliders 1151; 12 includes the oblique tongue dial 121 and the oblique tongue dial reset spring 122. The upper part of the oblique tongue dial is provided with an upper swing arm 1211, the middle part is provided with a oblique tongue dial fixing hole 1214, and the lower part is provided with a lower swing arm 1212. The lower swing arm 1212 is provided with a bolt hole 12121; the left side of the damper 13 is provided with a damper fixing hole 131, the right side is provided with a piston rod 132, and the right side of the piston rod 132 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com