Stamping equipment with waste collection function

A technology for stamping equipment and waste collection, applied in the field of stamping equipment, can solve the problems of time-consuming and laborious, no clamping device, increased labor force, etc., and achieve the effect of convenient use, reasonable structure and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

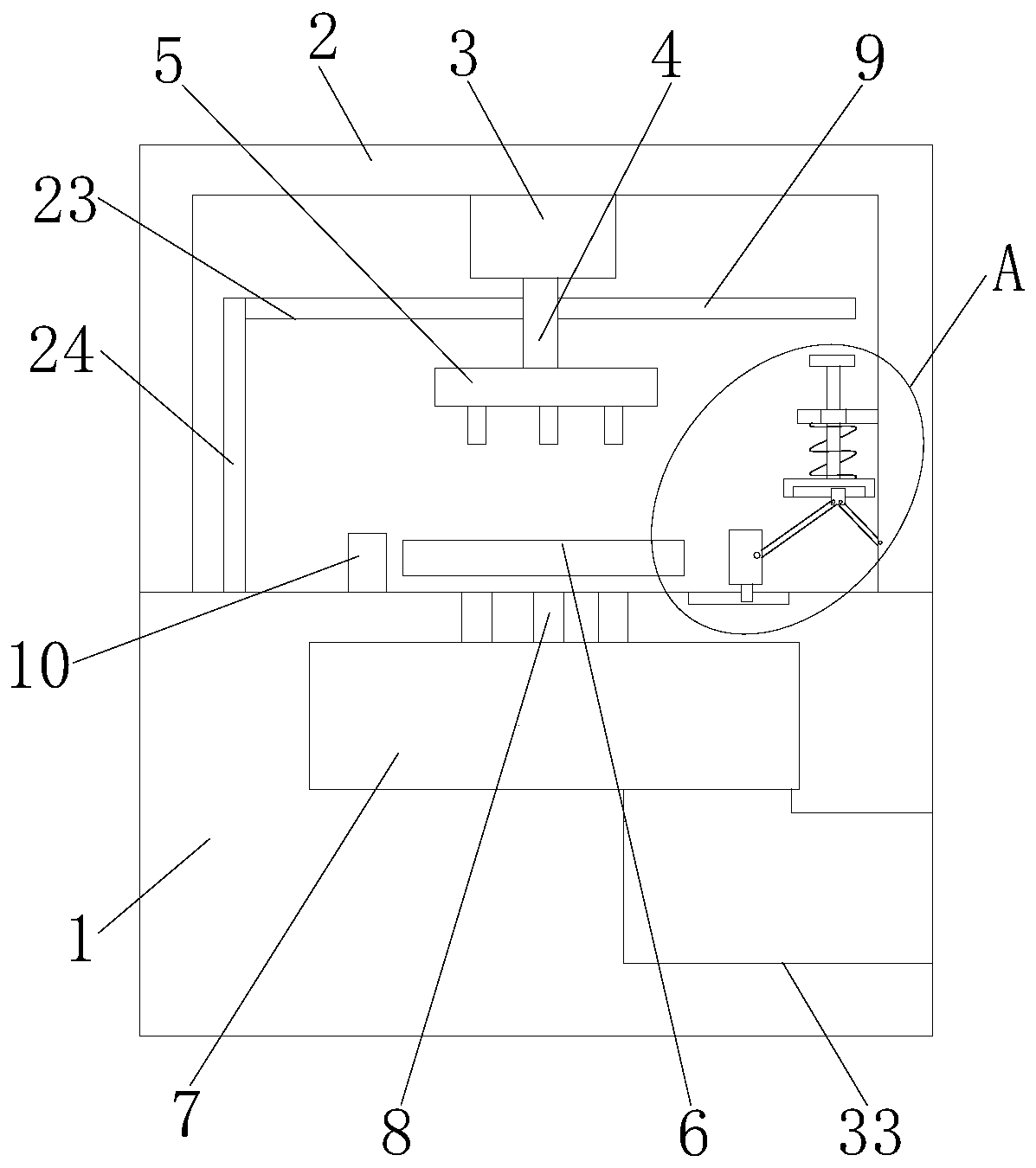

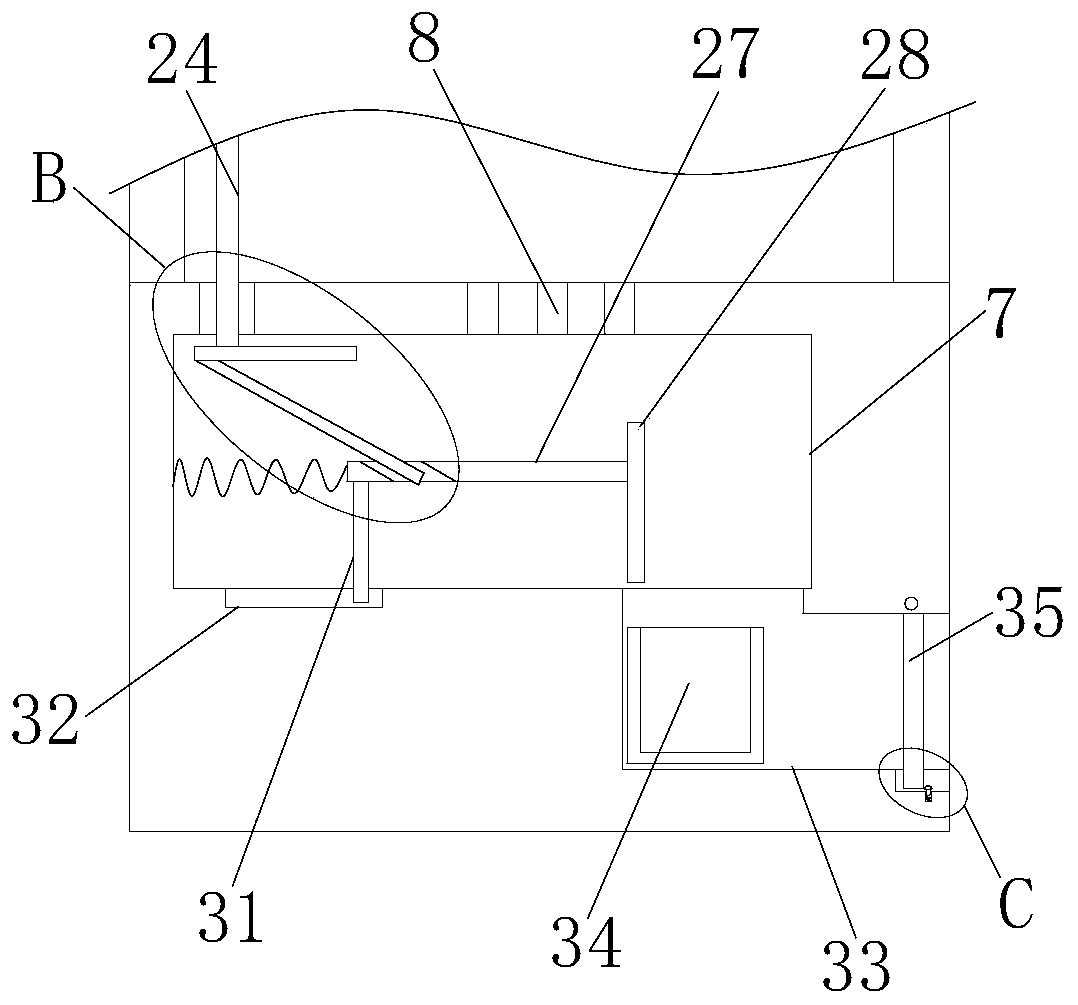

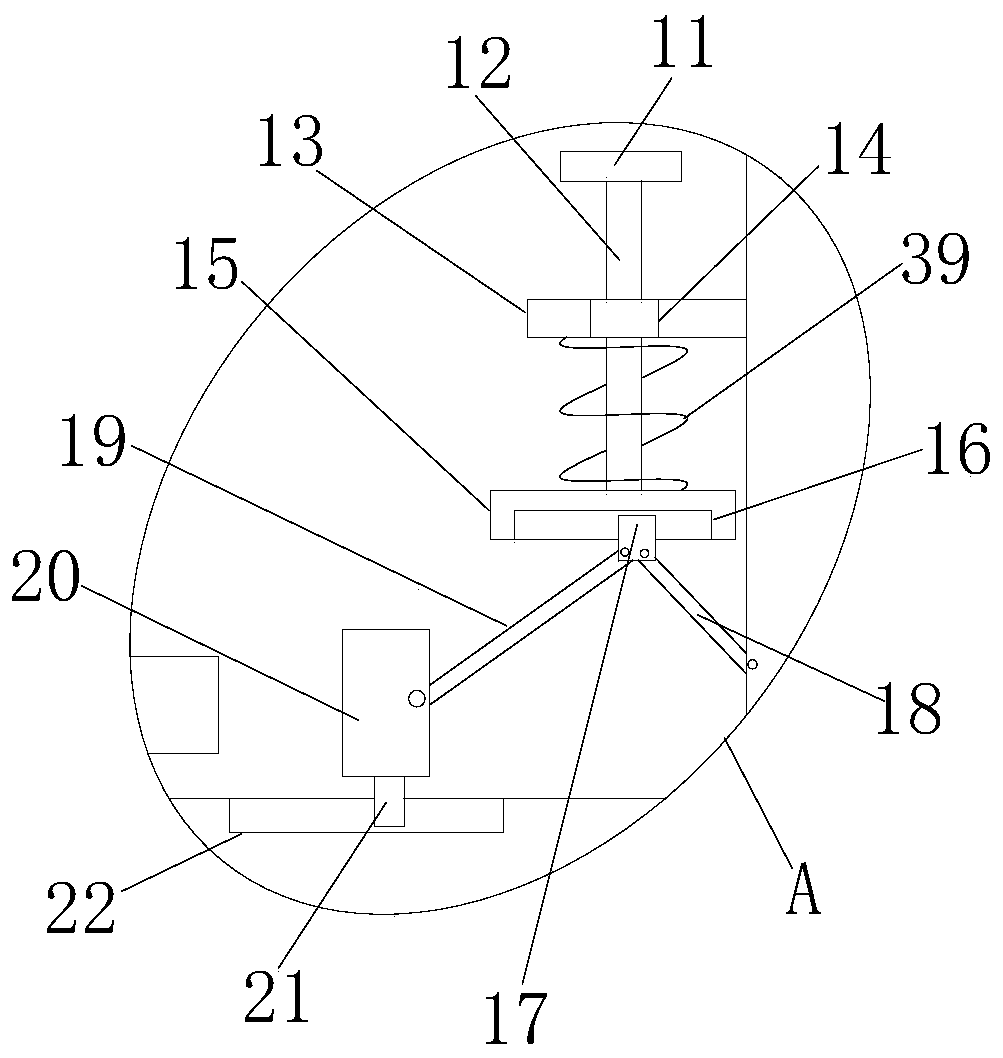

[0027] refer to Figure 1-5 , a kind of stamping equipment with the function of collecting waste materials, comprising a device body 1, an equipment frame 2 is arranged on the device body 1, a motor 3 is arranged on the device frame 2, a telescopic rod 4 is arranged on the motor 3, and the bottom end of the telescopic rod 4 A stamping head 5 is provided, a plate 6 is provided on the equipment body 1, a punching hole 8 is opened on the top side of the equipment body 1, a first installation rod 9 is fixedly installed on one side of the telescopic rod 4, and a movable installation is installed on one side of the equipment rack 2. There is a pressing plate 11, the top side of the pressing plate 11 is adapted to the first installation rod 9, the bottom side of the pressing plate 11 is fixedly equipped with a moving bar 12, and the bottom end of the moving bar 12 is fixedly equipped with a mounting block 15, and one side of the mounting block 15 A connecting rod 19 is installed mova...

Embodiment 2

[0038] refer to Figure 1-5 , a kind of stamping equipment with the function of collecting waste materials, comprising a device body 1, an equipment frame 2 is arranged on the device body 1, a motor 3 is arranged on the device frame 2, a telescopic rod 4 is arranged on the motor 3, and the bottom end of the telescopic rod 4 A stamping head 5 is provided, a plate 6 is provided on the equipment body 1, a punching hole 8 is opened on the top side of the equipment body 1, a first installation rod 9 is fixedly installed on one side of the telescopic rod 4 by welding, and a first installation rod 9 is fixedly installed on one side of the equipment rack 2. A pressing plate 11 is movable, and the top side of the pressing plate 11 is adapted to the first installation rod 9. The bottom side of the pressing plate 11 is fixedly equipped with a moving bar 12 by welding, and the bottom end of the moving bar 12 is fixedly installed with a mounting block 15 by welding. One side of the mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com