Two-way four- outlet concrete mixing station used for production of PC components

A mixing station and concrete technology, which is applied in the field of two-way four-exit concrete mixing plant, can solve the problems of less material outlets and low discharge efficiency, and achieve the effects of improving discharge efficiency, reducing work intensity, and meeting user needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

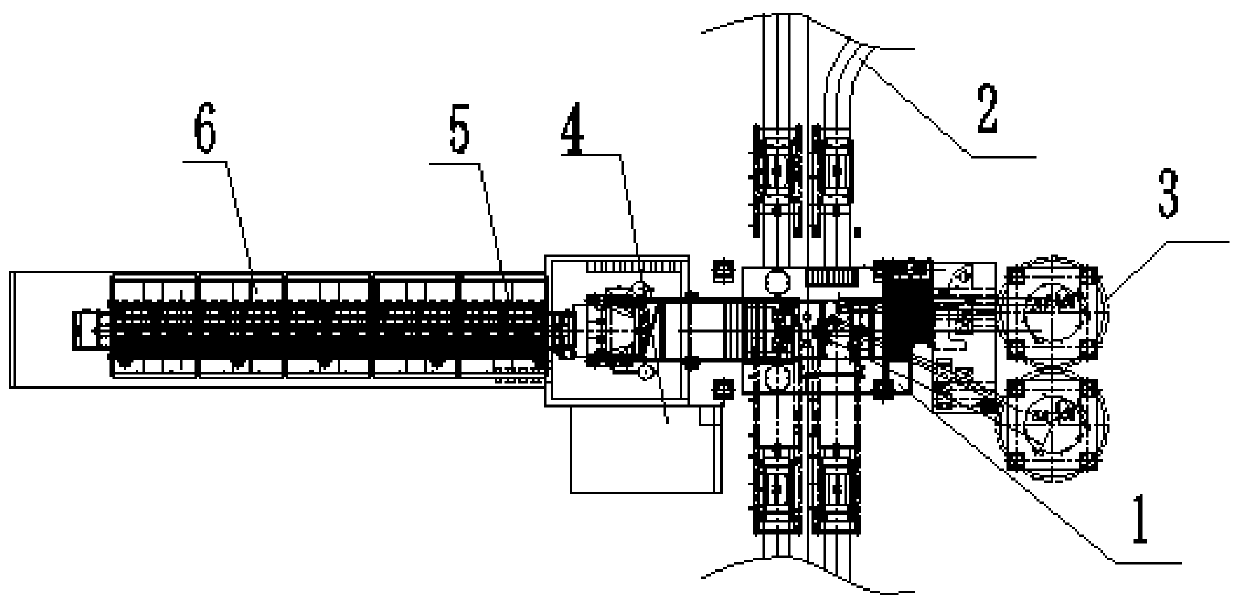

[0020] refer to Figure 1-3 , a two-way four-outlet concrete mixing plant for producing PC components, including a mixing plant body 1, four transport tank tracks 2 are arranged on the mixing plant body 1, and transport tanks are arranged in the four transport tank tracks 2, and the mixing There are two silos 3 on one side of the station body 1, three sand silos 5 on the other side of the mixing station body 1, and two stone silos on the side of the three sand silos 5 away from the mixing station body 1 6. A pool 4 is provided on one side of the mixing station body 1, and the pool 4 is located below the sand bin 5.

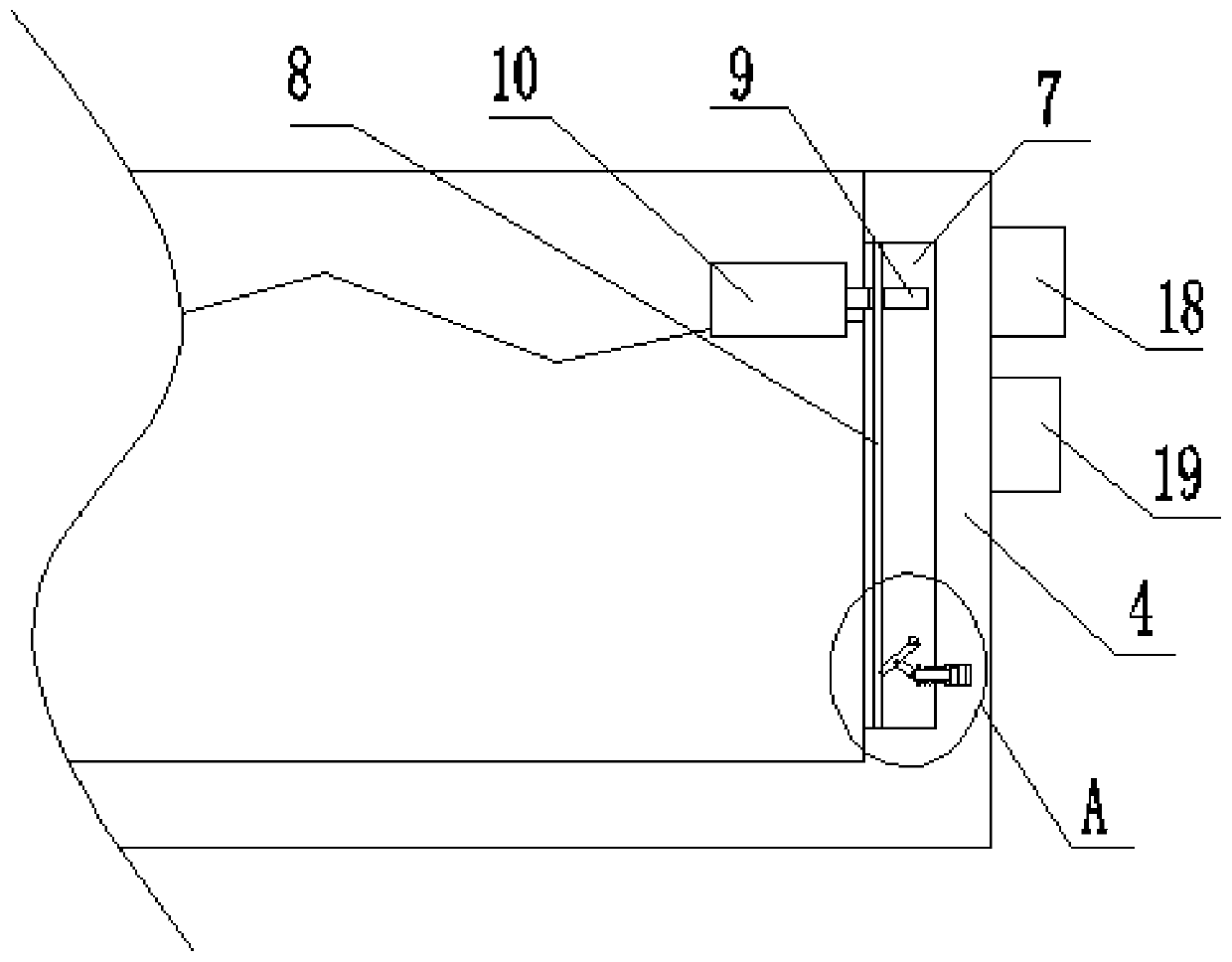

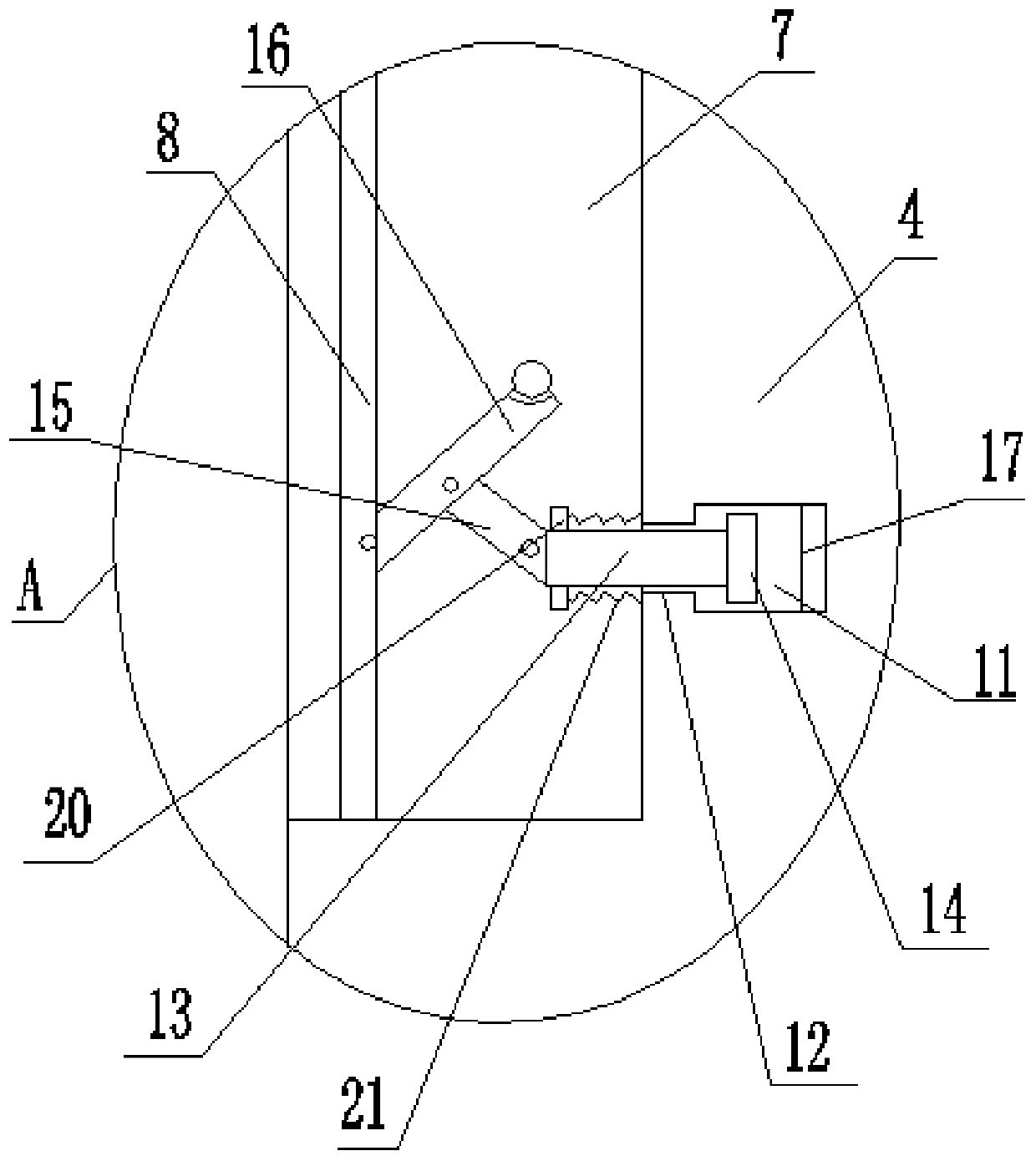

[0021] In the present invention, a chute 7 is provided on the inner wall of one side of the pool 4, and the same sliding rod 8 is fixedly installed on the inner wall of the top side and the bottom side of the chute 7, and a moving rod 9 is slidably installed on the sliding rod 8. Both ends of 9 extend to the outside of the chute 7, and one end of the moving rod 9...

Embodiment 2

[0028] refer to Figure 1-3 , a two-way four-outlet concrete mixing plant for producing PC components, including a mixing plant body 1, four transport tank tracks 2 are arranged on the mixing plant body 1, and transport tanks are arranged in the four transport tank tracks 2, and the mixing There are two silos 3 on one side of the station body 1, three sand silos 5 on the other side of the mixing station body 1, and two stone silos on the side of the three sand silos 5 away from the mixing station body 1 6. A pool 4 is provided on one side of the mixing station body 1, and the pool 4 is located below the sand bin 5.

[0029] In the present invention, a chute 7 is provided on the inner wall of one side of the pool 4, and the same sliding rod 8 is fixedly welded on the inner wall of the top side and the bottom side of the chute 7, and a moving rod 9 is slidably installed on the sliding rod 8. Both ends of 9 extend to the outside of the chute 7, and one end of the moving rod 9 ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com