Tire

A tire and tire circumferential technology, applied to tire parts, tire tread/tread pattern, rolling resistance optimization, etc., can solve the problems of inability to drain water, poor turning performance on dry roads, and reduced rigidity of the outer tread pattern, etc. problems, to achieve the effect of high lateral rigidity and excellent cornering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

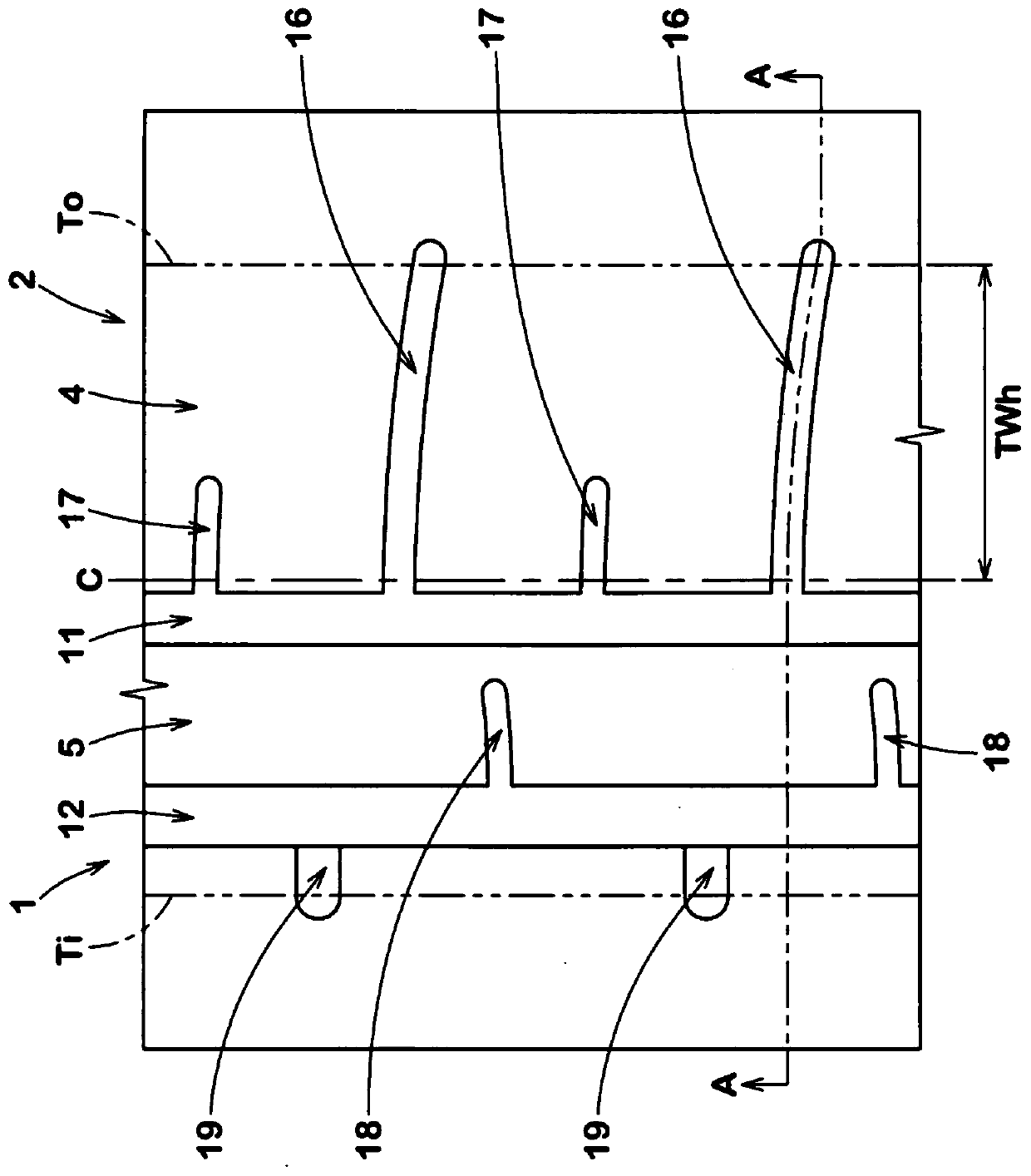

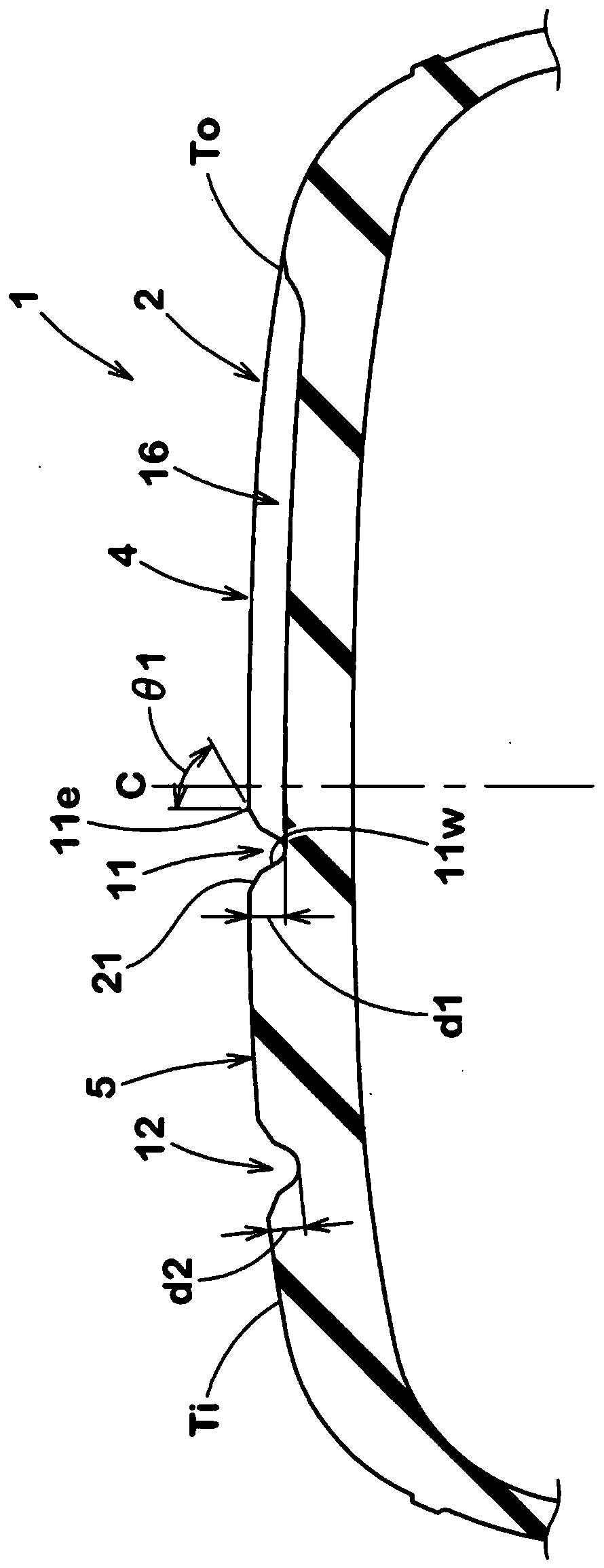

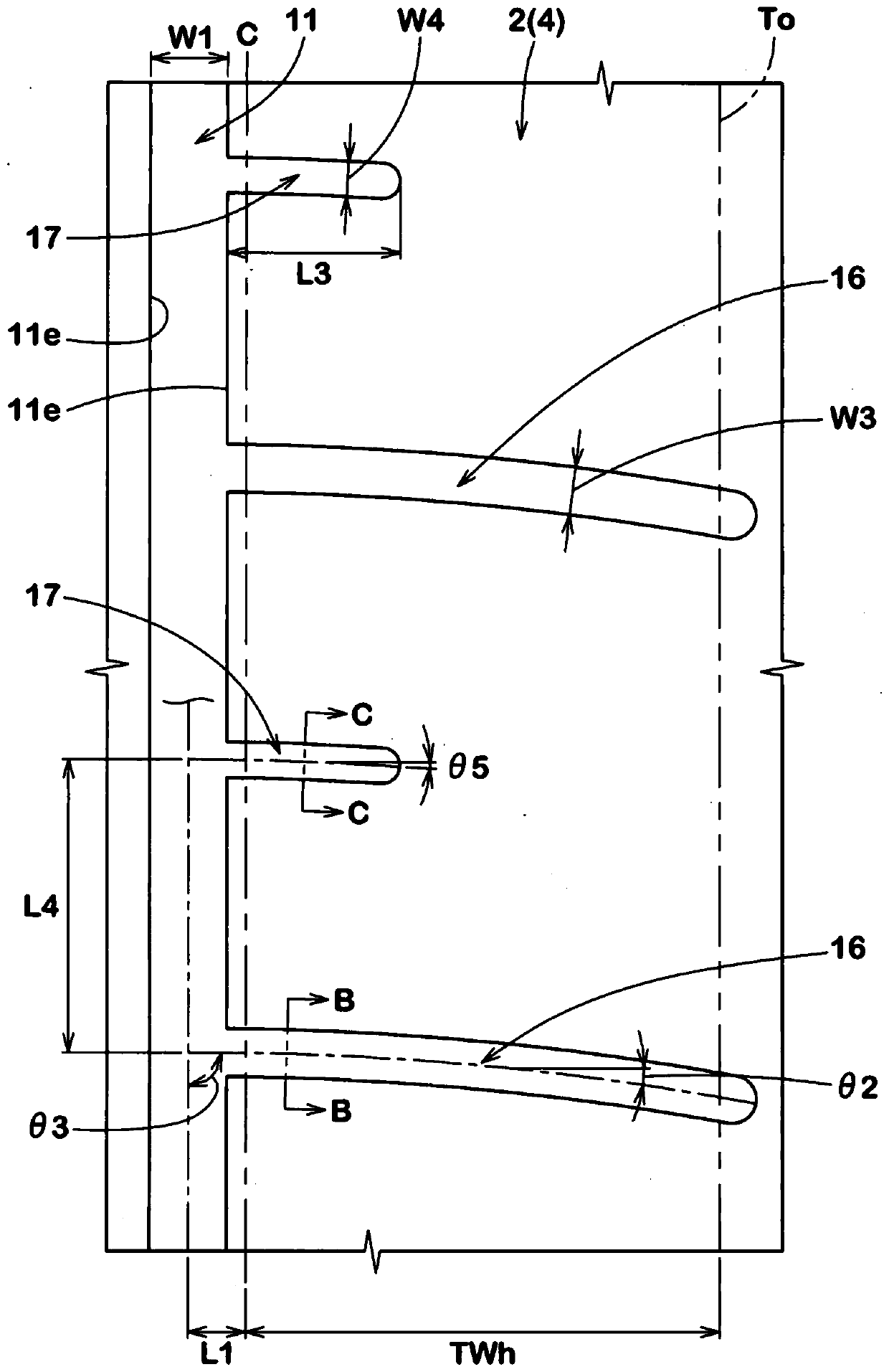

[0081] Based on the specifications in Table 1, a trial production with figure 1 The basic tread pattern is a tire of size 205 / 55R16. As a comparative example, such as Figure 7 The pneumatic tire shown has a main groove b provided in the outer tread portion a, and a plurality of lateral grooves c extending from the main groove b toward the outer tread edge To and interrupted in the outer tread portion a. The wet road performance and the cornering performance on a dry road surface of each test tire were tested. Common specifications and test methods for each test tire are as follows.

[0082] Rims: 16×6.5J

[0083] Tire internal pressure: 230kPa

[0084]

[0085] Using a built-in drum tester, the generation speed of the slipping phenomenon when each test tire was run on a drum surface with a water depth of 5.0 mm under the following conditions was measured. The results are an index based on Comparative Example 1 as 100. The larger the numerical value, the higher the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com