A refined hydrogen recovery device used in pta production process

A production process and recovery device technology, which is applied in the field of refined hydrogen recovery devices, can solve problems such as waste of resources, inability to eliminate hydrogen, and excessive hydrogen addition, and achieve the effect of ensuring elimination and ensuring moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

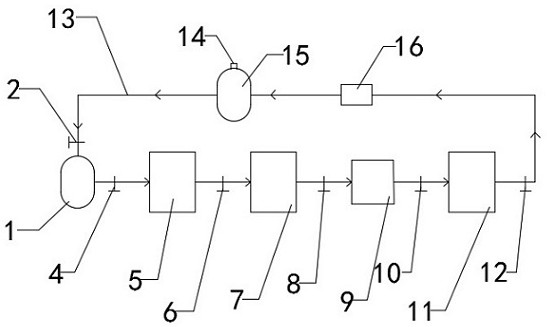

[0024] see Figure 1-3 , a refined hydrogen recovery device used in the PTA production process, comprising a PTA reaction body 1, the PTA reaction body 1 is connected to a gas cooling mechanism 5 through a connecting pipe 13, and the gas cooling mechanism 5 is connected to moisture through a connecting pipe 13 The separation mechanism 7 is connected, and the water separation mechanism 7 is connected with the hydrogen recovery mechanism 11 through the connecting pipe 13, and the hydrogen recovery mechanism 11 is connected with the gas collection tank 14 through the connection pipe 13, and the gas collection tank 14 is connected with the PTA reaction body 1 By connecting through the connecting pipe 13, the connecting pipe 13 between the PTA reaction body 1 and the gas cooling mechanism 5 is provided with a control valve-4, and the connecting pipe 13 between the gas cooling mechanism 5 and the moisture separation mechanism 7 A control valve two 6 is provided, and a control valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com