Suede three-prevention polyurethane leather for sofa furniture and preparing method thereof

A polyurethane and synthetic leather technology, applied in textiles and papermaking, can solve the problems of difficult process control, weak velvet effect, not waterproof and anti-fouling, etc., and achieve the effect of reducing damage, strong surface velvety, and anti-fouling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing polyurethane synthetic leather for suede three-proof sofa furniture, comprising the following steps:

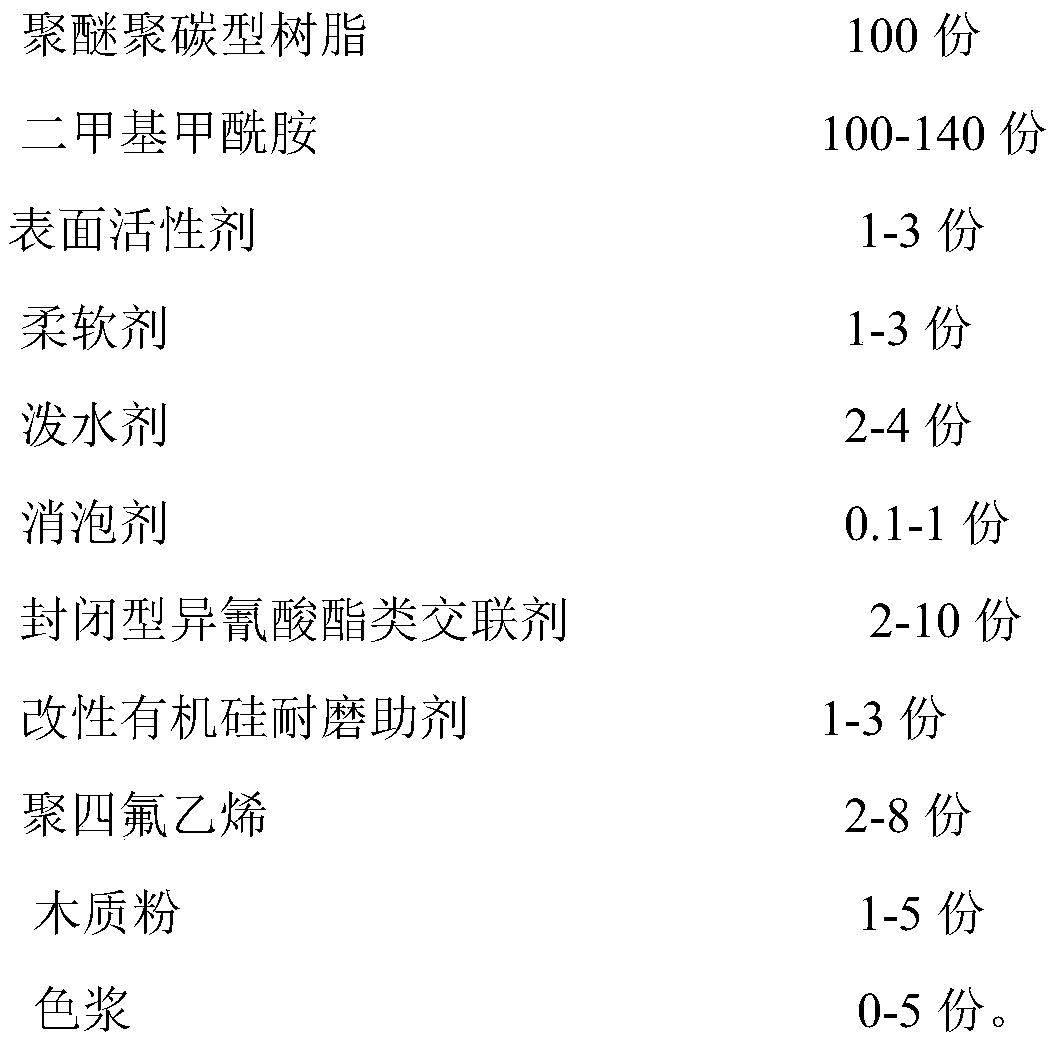

[0032] (1) Prepare wet-process polyurethane slurry as impregnating slurry, with the raised surface of the single-faced fleece substrate facing up, and the thickness of the single-faced fleece substrate is 0.65mm. After impregnating the single-faced fleece substrate, pass through The DMF solution is coagulated, washed with water, and dried to obtain a wet-process semi-finished product with a thickness of 1.0mm, which is denoted as S0; wherein, the wet-process polyurethane slurry is prepared by parts by weight from the following components:

[0033]

[0034] (2) Use a roller-type dermabrasion machine to sand the surface of the wet-process semi-finished product to obtain a semi-finished product with a velvet feel. The sandpaper used for the sanding is 240 mesh, and the smooth wool and the reverse wool are sanded once, and the wool feels after sand...

Embodiment 2

[0051] A method for preparing polyurethane synthetic leather for suede three-proof sofa furniture, comprising the following steps:

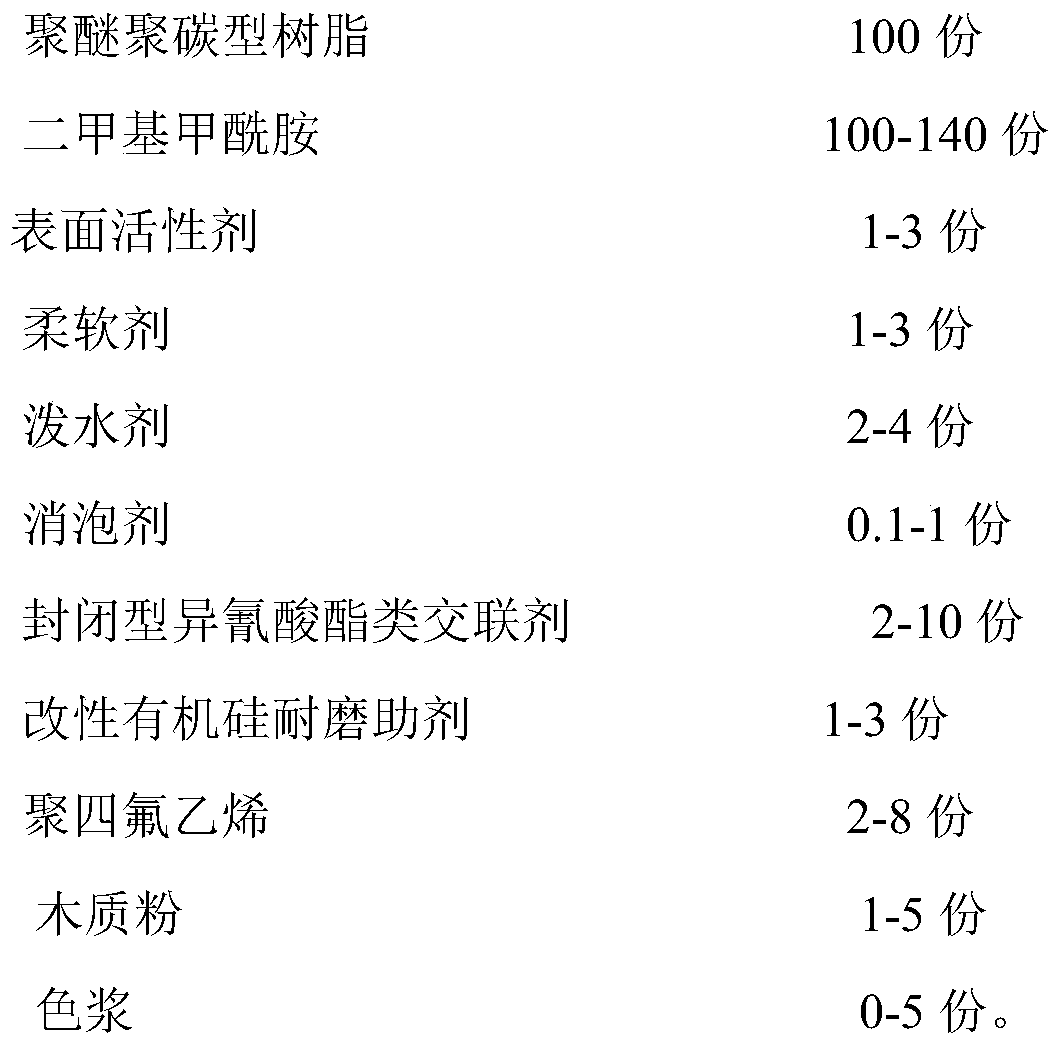

[0052](1) Prepare the wet-process polyurethane 3 urethane slurry as the impregnating slurry, with the raised side of the single-face fleece substrate facing up, and the thickness of the single-face fleece substrate is 1.0 mm. After impregnating the single-face fleece substrate , followed by DMF solution coagulation, washing, and drying to obtain a wet-process semi-finished product with a thickness of 1.3 mm; wherein, the wet-process polyurethane slurry is prepared from the following components by weight:

[0053]

[0054] (2) Use a roller-type dermabrasion machine to sand the surface of the wet-process semi-finished product to obtain a semi-finished product with a velvet feel. The sandpaper used for the sanding is 200 mesh, and the smooth wool and the reverse wool are sanded once, and the wool feels after sanding. The thickness of the semi-fin...

Embodiment 3

[0061] A preparation method of polyurethane synthetic leather for suede three-proof sofa furniture, comprising the following steps:

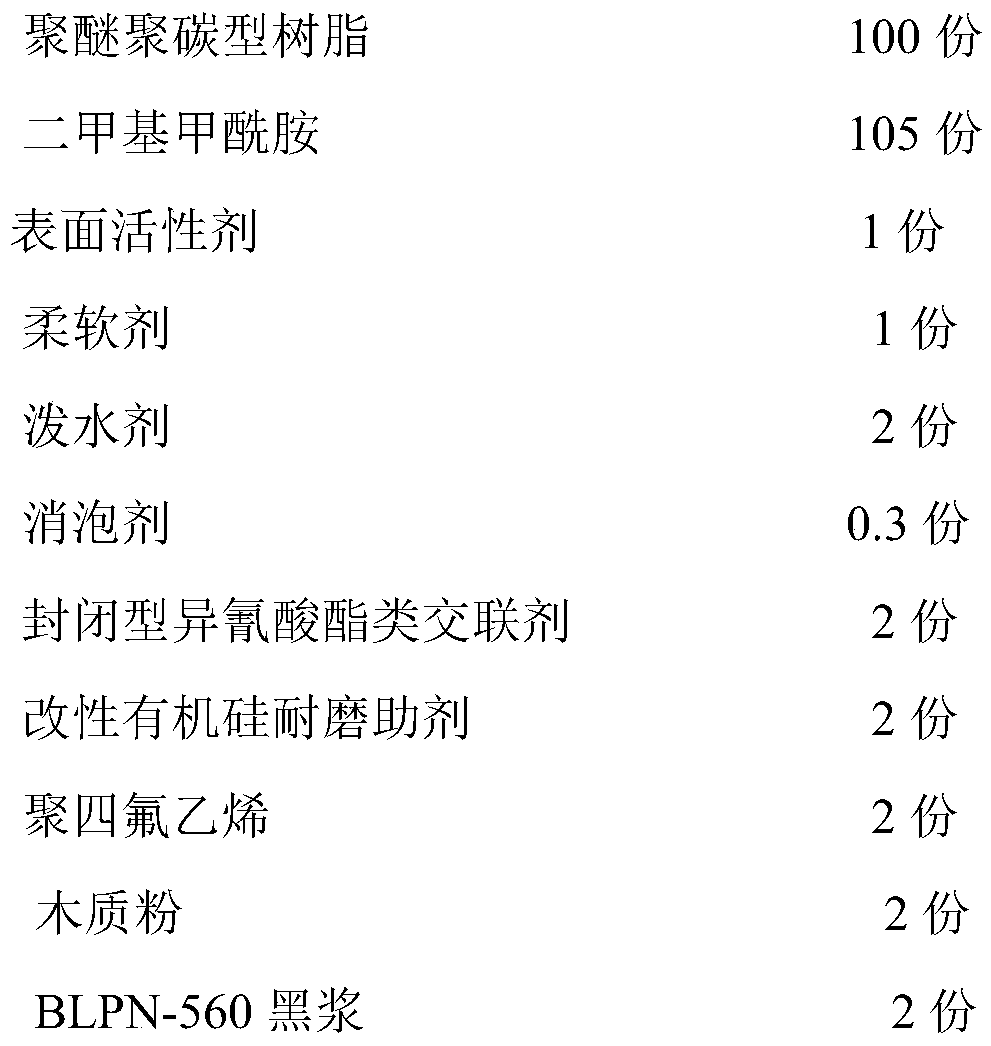

[0062] (1) Prepare the wet-process polyurethane slurry as the impregnating slurry. The raised surface of the single-faced fleece substrate faces up, and the thickness of the single-faced fleece substrate is 0.75mm. After impregnating the single-faced fleece substrate, it is passed through The DMF solution is coagulated, washed with water, and dried to obtain a wet-process semi-finished product with a thickness of 1.2mm; wherein, the wet-process polyurethane slurry is prepared from the following components by weight:

[0063]

[0064] (2) Use a roller-type dermabrasion machine to sand the surface of the wet-process semi-finished product to obtain a semi-finished product with a velvet feel. The sandpaper used for the sanding is 180 mesh, and the smooth hair and the reverse wool are sanded once, and the wool feels after sanding. The thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com