Large-resistance three-line gauntleted track railway sleeper for automatically monitoring train state

A technology for train status and automatic monitoring, applied in railway transportation, railway transportation, tracks, etc., can solve the problems that manual inspection cannot meet real-time monitoring, track instability, easy to produce fatigue, etc., to reduce work intensity and missed inspections. possibility, eliminate operational hazards or failures, improve reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

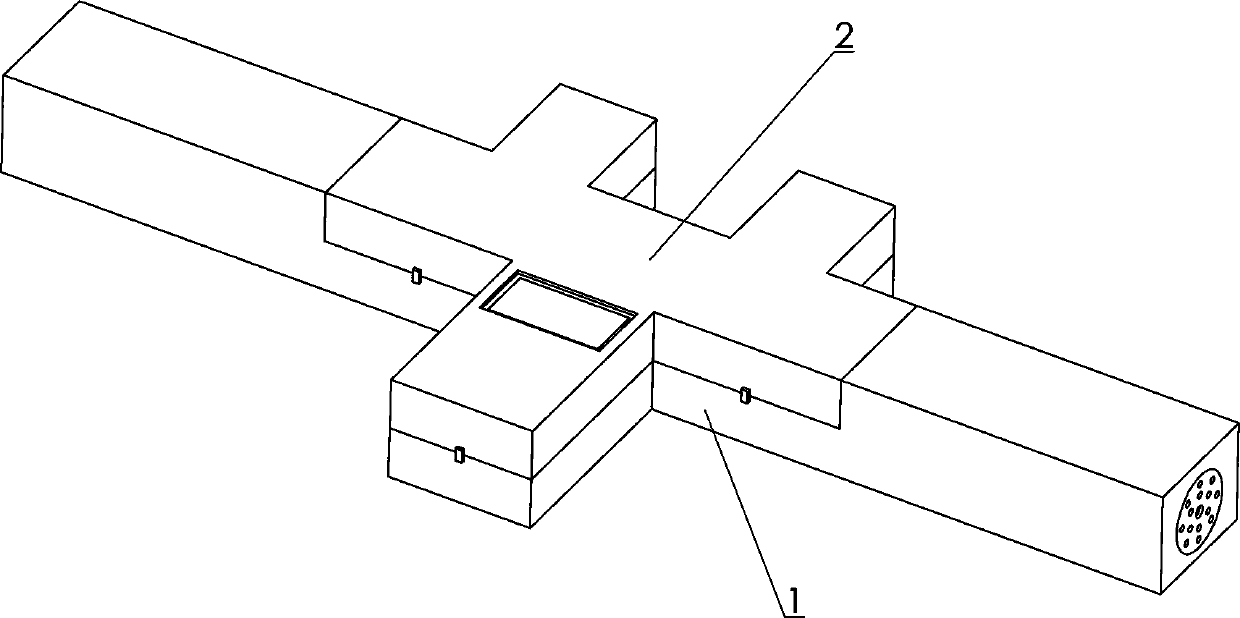

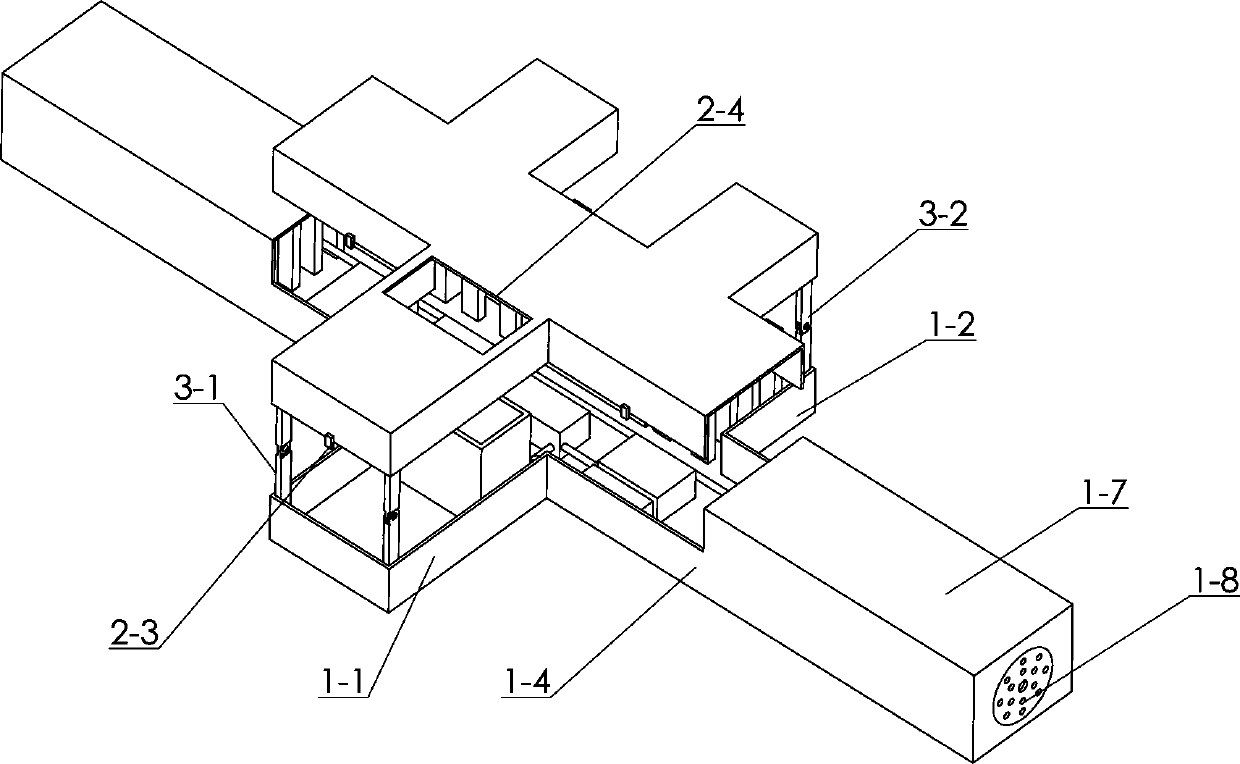

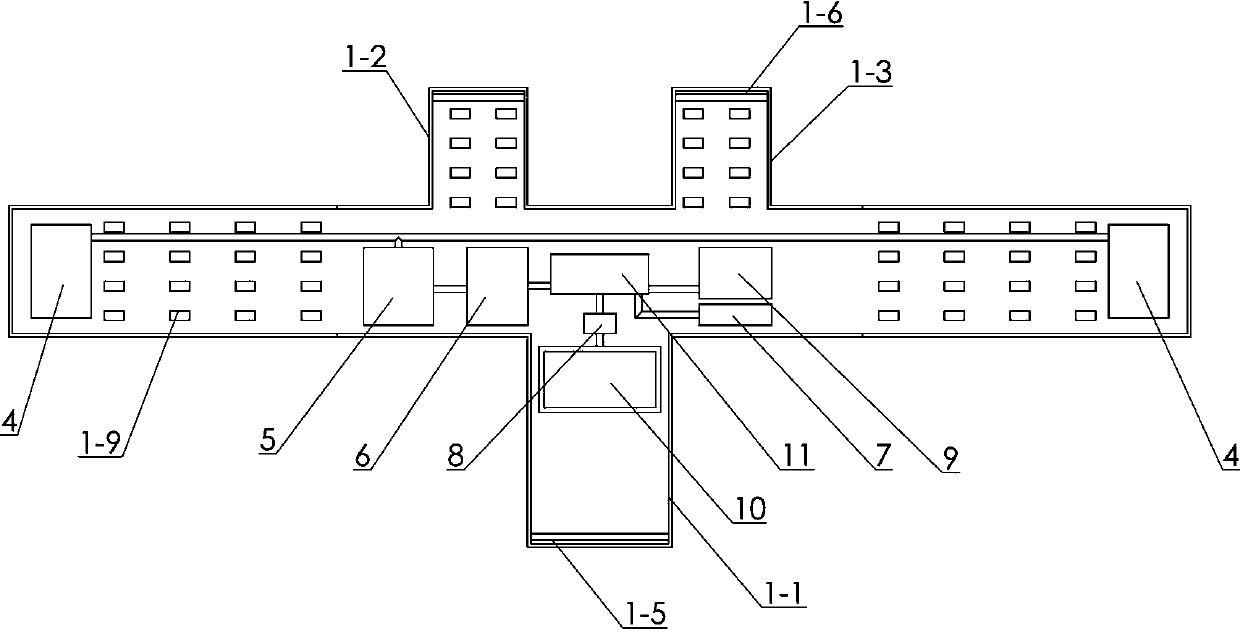

[0036] as attached Figure 1-4 As shown, the present invention includes a fixed sleeper 1, a moving sleeper 2 and a connecting assembly,

[0037] The fixed sleeper 1 includes a long rib 1-4, which is characterized in that the front end of the long rib 1-4 is provided with a first convex limit block 1-1, and the rear end is provided with a second convex limit block 1 -2 and the third convex limit block 1-3, the first convex limit block formed between the second convex limit block 1-2 and the third convex limit block 1-3 Block 1-1 is adapted to the connection groove, the first convex limit block 1-1 is provided with the first front connecting shaft 1-5, the second convex limit block 1-2 and the first The rear second connecting shaft 1-6 is arranged in the three-convex limit block 1-3,

[0038] Fixed protective covers 1-7 are arranged symmetrically at both ends of the long ribs 1-4,

[0039] The moving sleeper 2 is embedded in the groove between the fixed protective covers 1-7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com