Reinforced composite geotechnical cushion capable of preventing capillary barrier effect and manufacturing method thereof

A composite geotechnical and reinforcement technology, applied in geotextiles, excavation, soil protection, etc., can solve problems such as landslides, slope instability, and inability of rainwater to infiltrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

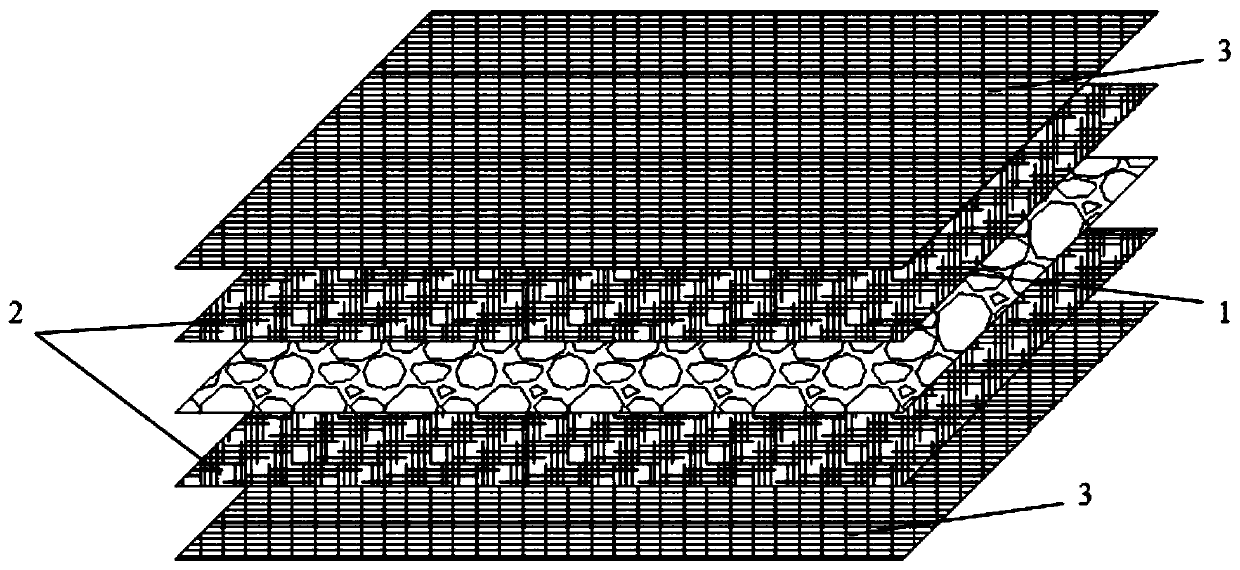

[0016] A reinforced composite geotechnical cushion for anti-capillary barriers, the overall structure of which includes three parts: a crushed stone silk layer, a hot-melt plastic silk layer, and a reinforced grid layer.

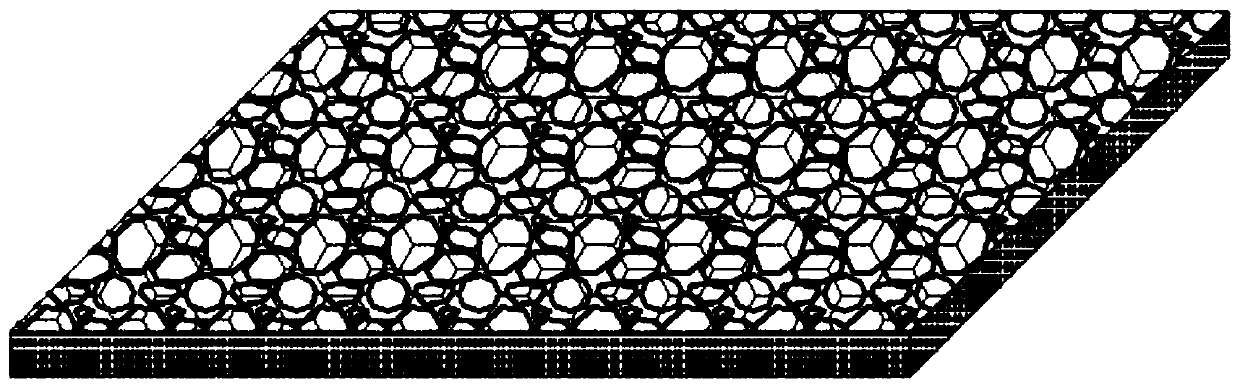

[0017] The crushed stone and silk layer in the structure 1) is made of crushed stone with a single particle size group mixed with rayon or natural hemp, which has strong water permeability, large pores, and small capillary action;

[0018] The hot-melt plastic filament layer 2) in the structure is a plate-shaped porous structure formed by spraying hot-melt plastic into filaments and cooling in a flat mold;

[0019] The reinforced grid layer 3) in the structure is a square grid structure, which is made of plastic with tensile strength. The warp and weft are interlaced to form a porous grid structure. The divided square cells have only four walls and no upper and lower bottoms. .

[0020] The manufacture method of the reinforced composite geotechnical cushion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com